Tooling up: The Hoffmann Group - where distribution meets consultancy

MACH 2016 provided the ideal platform to find out more about tooling specialist the Hoffmann Group. This is after all a €1.1 billion turnover organisation that employs more than 3,000 people in over 50 countries with more than 135,000 customers globally – yet the business is still relatively unknown in the UK. Dave Tudor believes it’s time to put the record straight.

German manufacturing companies are often family-run businesses and Hoffmann falls squarely into that category. Now in its fourth generation of family ownership, it started life way back in 1919. CEO Reinhard Banasch is breaking with tradition though; recruited in 2014 he’s the first non-family CEO ever employed by the company.

“As you can imagine the company has seen a lot of changes since its inception,” he observes. “We started purely as a Bavarian manufacturing company/tooling dealer; then grew the business into other parts of Germany before evolving into the true global organisation we are today.

We have 25 subsidiaries around the world and six partner companies – three in Germany and others in Switzerland, Sweden and Lithuania. What's more, longstanding distribution partnerships in a number of key markets provide us with additional sales and support channels globally. We are still growing in Europe but worldwide we’re also focusing on four key markets – South East Asia, Mexico, the US and India.”

An interesting aspect of Hoffmann’s business is that apart from an industrial furniture production division specialising in workstations and storage systems, it doesn’t actually manufacture any products itself. The company is essentially a cross between a consultant and a distributor; it has a vast span of products in its portfolio from a multitude of leading manufacturers, as well as its own premium Garant range, but it also employs around 1,200 field-based specialist consultants that work closely with clients to ensure that the right solution for a specific application is provided.

Some customers of course will just call to buy new drills, taps or endmills off the shelf, but others have more complex manufacturing conundrums to solve. This is Hoffmann’s strength – it’s a true solutions provider and if it can’t provide the right product from the range, it’ll work with the customer to source a solution.

People power

At the heart of Hoffmann’s success is its people. New employees often have a strong tooling background before they join the company but irrespective of experience, all undertake an extensive six month training period before being ‘let loose’ into the marketplace. As Mr Banasch explains, on the sales side there are effectively four tiers of support that a customer can access.

“The first level is a sales representative that looks after a specific region,” he says. “His or her product knowledge is pretty good but if things need to go to the next level then there’s two levels of applications specialists on hand. Then if things get really technical, the product managers step in. It’s a very effective system that works really well; some customers may call simply to order a tool whilst others may need support for a highly complex turnkey project. In either case, we have the infrastructure to help the customer.”

A case in point was a large turnkey project undertaken last year. Around 70 40ft Hoffmann container lorries full of mainly storage racks, tool vending cabinets and workstations were shipped and installed by the company at the new Audi manufacturing plant in Puebla, Mexico. Logistically, Mr Banasch believes that only a few companies in the world could handle projects of this magnitude.

Online and in print

The Hoffmann catalogue is at the centre of the company’s operations and it contains a mind-bogglingly huge and diverse selection of products – everything from HSS drills, solid carbide drills, taps and countersinks through to reamers, saw blades, metrology equipment, workholding products, hand tools and tool vending solutions. Mr Banasch believes that not manufacturing any products in-house is not restrictive in any aspect: “Our business model is similar to Apple or Nike,” he reveals. “Those companies don’t actually manufacture products themselves yet their brands are seen as market leaders in their respective fields.

“Our catalogue carries many carefully selected products from leading manufacturers and we employ 150 product managers to support the application of those products. However we are adding new suppliers all the time because we are 100% focused on supplying the right solution to the customer, whatever it takes.

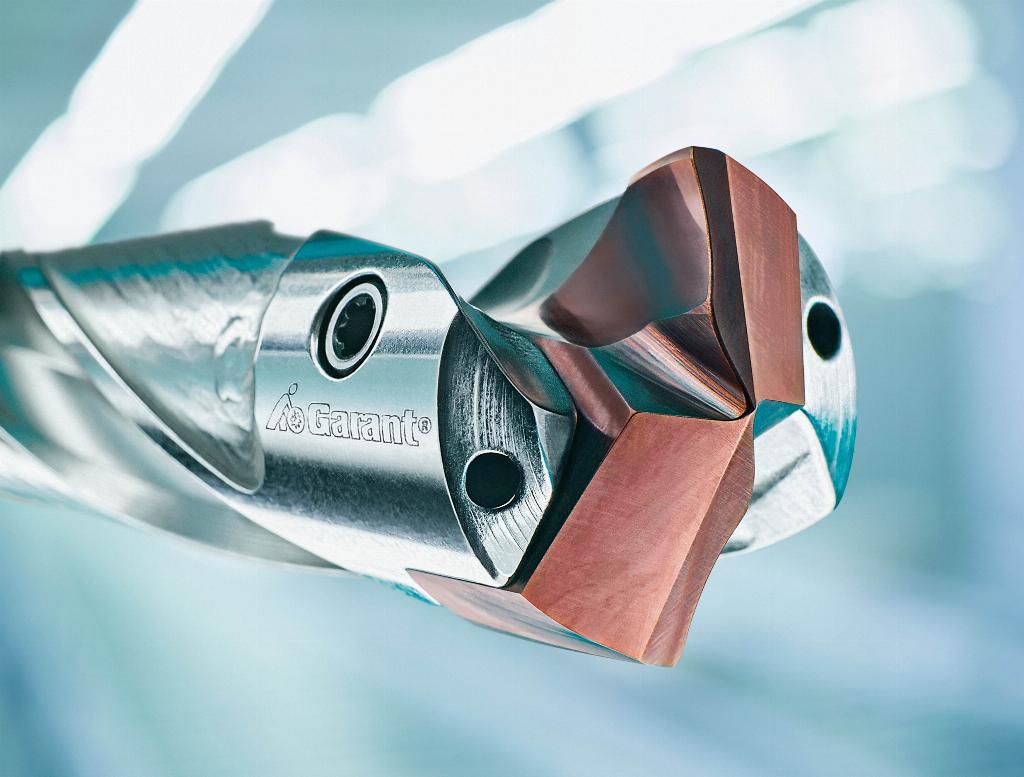

“Sometimes we’ll take a product and work with the manufacturer to improve it,” Mr Banasch adds. “Those items are then rebranded under our own Garant brand and sold as premium products. It’s a win-win situation: the manufacturer is happy because he’s partnering with us to actually improve the product resulting in more sales for both parties; we’re happy because we establish strong partnerships with our suppliers which reinforces and strengthens our own Garant brand; and the customer is happy because he or she is getting the right tool for the job.”

On the subject of catalogues, surely in 2016, in the largely digital world we live in, there’s no need to print paper versions of this somewhat weighty tome? Mr Banasch emphatically disagrees: “In 2005, someone within the company predicted that by 2015 there would be no need to have a printed catalogue. Last year we printed half a million copies in 18 languages. Of course having an online presence is vital too – we have 500,000 products available.”

Premium products

Hoffmann’s premium Garant range has seen unquestionably meteoric levels of growth since it was initially introduced in 1973. More than 25,000 products encompassing machining, clamping technology, measuring tools, grinding and separating technology, hand tools, workstations and storage make up the range with the brand having its own development team and test centres. 99% of Garant stock items are available from the Hoffmann Group within 24 hours in Germany and 48 hours in the rest of Europe. Its 36,000m² warehouse in Nuremberg holds €120 million worth of stock and ships 60,000 items a day.

“Garant’s objectives are clear,” Mr Banasch explains. “From a performance perspective, the products need to be as good or better than anything available in the marketplace.”

In addition to the physical products, the Garant family also includes a range of tooling services branded under the ‘Garant 360° Tooling’ umbrella. These comprise: eTool downloadable 2D/3D CAD/CAM data for 500,000 tools; ToolScout (www.toolscout.com) which enables application orientated searches for mono/modular tools as well as direct comparison of cutting data; and ToolGrinding which is a tool regrinding service that claims to restore tools back to their ‘as new’ original condition – to the same geometry and inclusive of any coatings that were part of the original specification and at a fraction of the price of new tooling. This is guaranteed because the tools are reground on the same machines as they were originally manufactured.

A notable new product from the Garant range showcased on the Hoffmann stand at MACH was the Tool24 Smartline storage solution for the procurement, storage and issuing of tools. The Smartline system is completely modular meaning it can be expanded at any time. Sturdily constructed tool cabinets with up to 90 drawers offer round the clock access and intuitive software allows selections to be made via scanner, keyword search or part number.

Smartline can be accessed through a pin/password system, RFID access or fingerprint and a network interface facilitates linking to a company network and/or ERP system. Hoffmann can manage the entire monitoring/reordering process seamlessly because everything is automated. In addition, the system offers detailed management reporting capabilities.

UK operations

Hoffmann’s market presence in the UK is on the rise with a recruitment drive planned for the near future. Currently there are nine members of staff in the UK – eight field sales engineers and regional manager Phillip Meechan who heads up the team. In Achim near Bremen in Northern Germany, the UK operation is supported by six dedicated internal sales engineers.

“Business has grown year on year in the UK and we’ll be expanding the operation in the future with the recruitment of more field sales engineers and an additional regional sales manager so things can be territorially split north and south,” Mr Meechan advises.

Ethically speaking

Away from business, the Hoffmann Group is an intensely ethical and socially responsible company. For many years the Hoffmann family and employees alike have engaged socially – and financially – with society, helping underprivileged, sick and abused children get a decent chance in life. In 2006 these activities culminated in the setting up of the Hoffmann Group Foundation and in 2010 the Orange House was officially opened.

“The Orange House is a creative centre for children located in upper Bavaria,” Mr Banasch explains, “and it provides a safe haven for kids that have perhaps been abused, have serious injuries or even may be terminally ill.

“I’ve been there several times and through our instructors there, it’s fascinating to see how much the children enjoy getting involved in making things. It gives them a real purpose in life and it can really make their problems seem less significant if only for a short time. We’re all very proud of the Foundation and there are plans to build a similar facility in Northern Germany.”

And proud it should be. The Foundation takes care of all operating and maintenance costs of the Orange House and since opening, it has helped more than 2,500 children.

Hoffmann Group www.hoffmann-group.com