Turning to a new partnership

Mastercam, has partnered with Sandvik Coromant to bring the industry’s first automated CAM support to the cutting tool specialist’s new PrimeTurning innovation.

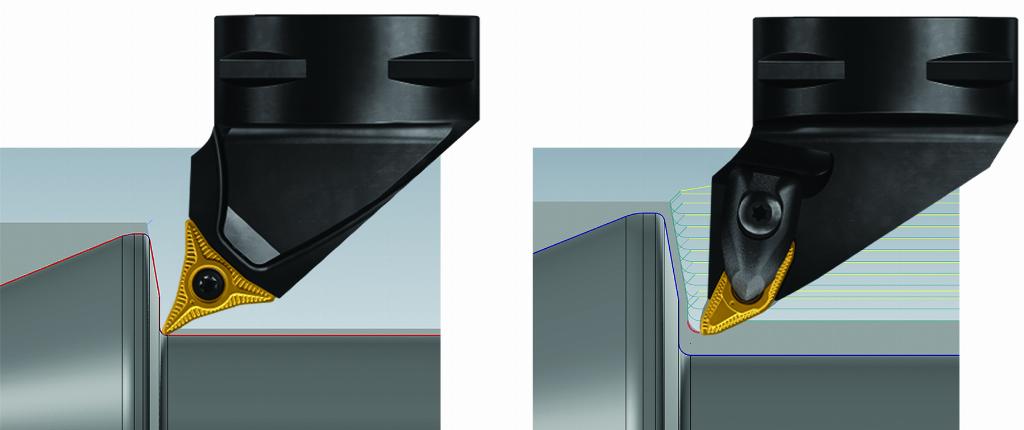

A new set of Mastercam turning strategies, scheduled for the upcoming Mastercam 2018 release in June, supports Sandvik Coromant CoroTurn Prime inserts and the PrimeTurning technology. These automated strategies simplify CAM programming for these inventive inserts capable of increasing productivity by as much 50-80%, achieving high material removal rates, and doubling tool life over conventional inserts currently in use.

Mastercam worked closely with the Sandvik Coromant product line management and technical specialists to implement its patent-pending PrimeTurning methodology for performing turning operations in all directions within Mastercam’s standard product.

These specialised toolpath strategies take full advantage of CoroTurn Prime insert designs to achieve high material removal rates and improved tool life. Mastercam 2018 supports both CoroTurn Prime A-type inserts designed for roughing, finishing, and profiling, and B-type inserts for heavy roughing applications.

These automated toolpaths allow programmers to achieve high productivity gains in ISO P steels, ISO M stainless steels, and ISO S heat resistant super alloy (HRSA) materials.

“The Sandvik Coromant PrimeTurning method and new CoroTurn Prime inserts represent a game-changing development for turning, and we’re thrilled to partner with Sandvik Coromant to help bring this innovation to the market,” says Meghan West, president of CNC Software which develops Mastercam.

“We are excited that our users will be some of the first to benefit from this industry breakthrough. With the widest installed base of any CAM system, we’re eager to see the many ways Mastercam users will capitalise on this ground-breaking advancement.”

“It’s not very often that real innovative solutions are introduced to the metalcutting industry. However, the PrimeTurning method is without doubt one of these things. After intense research and development and extensive testing, we can now proudly state that this is the biggest innovation in turning since turning,” affirms Mia Pålsson, senior manager product unit turning tools at Sandvik Coromant.

“To really benefit from the huge potential, this method requires correct and smart programming. We are therefore proud to work together with CNC Software to support our common end users.”

Scheduled for release in June 2017, toolpath strategy support for Sandvik Coromant PrimeTurning method will be included within the Mastercam 2018 release, free of charge, to all new seats and maintenance customers of Mastercam Lathe Level 1 and mill-turn products.

MASTERCAM www.mastercam.com/primeturning

SANDVIK COROMANT www.sandvik.coromant.com