Where will metrology be in the next 5-10 years?

Metrology has come a long way since its conception during the era of the pharaohs. Measurement Solutions’ managing director Iain Caville gazes into his crystal ball and predicts developments over the next five to ten years.

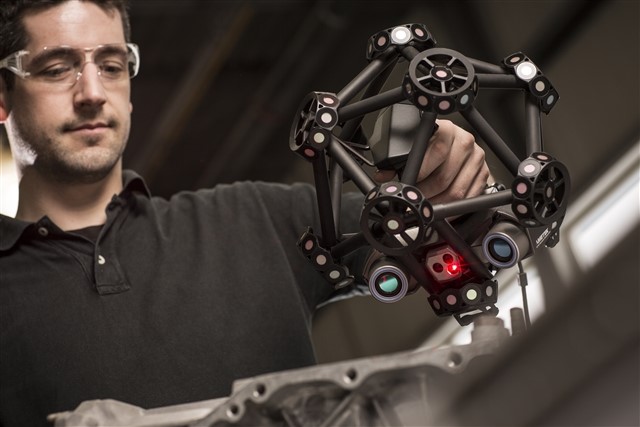

Metrology evolution is unrelenting and ongoing but it would be true to say that developments have been particularly rapid in the last 25 years with the advent of lasers, 3D scanners, and optical technology.

Therefore, it is logical to consider that this field will continue to evolve even further to improve quality control and inspection, and that new developments will change manufacturing processes. Here, we take a brief look into the future to see what metrology solutions and metrology equipment might look like in five to ten years. Here are the revelations from our crystal ball.

One thing is for sure – inspection will move away from the metrology laboratory to become fully integrated into shopfloor processes and the keys to this transition will be equipment portability, simplicity, and flexibility. Moreover, measurements will be performed without the need for human intervention and manufacturing processes will self-correct based on these automated measurements.

Measurement closer to manufacturing

Now that metrology equipment is moving closer to the production floor, its simplicity and ease of use will become mandatory to enable those who manufacture the parts to also inspect them. Inspection and quality control will no longer be considered as a parallel procedure, but rather an integral part of the manufacturing process. Measurements will occur on several occasions during the manufacturing, so that the manufactured part will have already been measured at several key locations before completing its production process.

Simplicity and flexibility

More operators will be asked to perform quality control and inspection directly on the production floor and metrology equipment will be intuitive, simple to use, and easy to understand. The level of expertise required to operate this equipment will decrease. Moreover, there will be a transition period where inspection will still be managed by quality control teams, who may not necessarily be familiar with automation and robot programming, and will progressively move to production teams that may not be completely used to measuring methods. Metrology will have to rely on flexible solutions during this period to get measurements, which will soon be automated and self-corrected.

3D scanning

Another thing we can be certain of is that 3D scanning metrology solutions will gradually replace traditional probing solutions for three major reasons: speed of acquisition, density of information analysed, and the short time required to characterise a complete part. Scanning devices will need to be far more flexible than those generally available today, most of which currently exhibit many limitations when applied to a wide spectrum of activities.

Software and hardware integration

In the future, there will be better synergy between each of the system components and standardisation of software across multiple devices will be vital. Indeed, both metrology equipment hardware and software will be jointly developed to fully interact, operate and give users maximum capabilities. Therefore, generic software compatible with single devices will give way to an integration of all devices. It will allow for more possibilities and provide users with important benefits, especially in terms of simplicity and ease of use.

Automation

In the future, human intervention during inspection will be replaced by fully automated measurement systems. Since programming may quickly become a nightmare for quality control teams, they will prefer to use flexible and intuitive software integrated with the hardware. Ultimately, with collaborative robots becoming available, it could be as easy as manually making a motion, so the robot can record and program its own movement and trajectory independently.

Finally, smart measurements, as documented in Industry 4.0, will completely modify the production process. Based on automated measurements by the metrology systems, manufacturing processes will be able to auto-correct, even without human intervention.

At Measurement Solutions we have partnered with some of the leading metrology technology and software specialists to be able to effectively combine solutions according to specific needs.

Measurement Solutions www.measurement-solutions.co.uk