ABB Seminar: improving productivity with robots

ABB’s forthcoming Switch to Robots seminar (http://bit.ly/S2RMar2017) will explain how ongoing reductions in the cost and complexity of robotic automation are opening up new opportunities for UK SME manufacturing companies.

ABB’s forthcoming Switch to Robots seminar (http://bit.ly/S2RMar2017) will explain how ongoing reductions in the cost and complexity of robotic automation are opening up new opportunities for UK SME manufacturing companies.

Taking place at ABB’s Milton Keynes site on Wednesday 15th March 2017, the event will provide a simple step-by-step guide to introducing robot automation to the factory floor.

The seminar provides a step-by-step guide to the key issues around specifying, installing and operating a robot, including how to assess which processes can be automated and how to develop the right solution for your needs. Other topics covered will include how to calculate the potential return on investment that can be achieved in different types of applications.

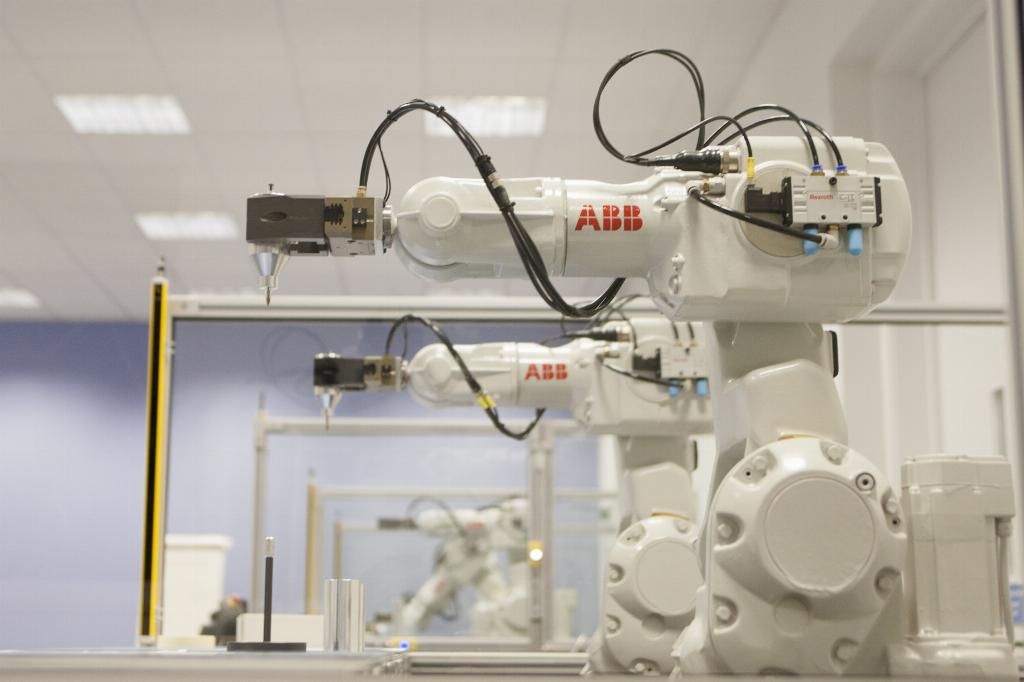

There will also be a hands-on workshop session in ABB’s training centre, providing the opportunity to see and use some of the latest robot technology, including ABB’s RobotStudio offline programming software, which helps to significantly reduce the time and cost of setting up a robot system by enabling robot cells to be modelled and tested offline.

“Misconceptions about the cost, flexibility and complexity of robots are stopping many small to medium UK manufacturing companies from realising their true potential,” commented Mike Wilson, general industry sales manager for ABB Robotics in the UK and Ireland.

“Our ‘Switch to Robots’ event has been designed to help businesses identify whether a robot could be beneficial and explain the steps they need to take in specifying and installing the best solution for their requirements.”

To book your place, email robotics@gb.abb.com or call 01908 350300, ref: ‘Switch to Robots seminar - March’ or visit the weblink below.

Switch to Robots seminar http://bit.ly/S2RMar2017