Seamless integration

Pete Baxter, vice president of digital manufacturing at Autodesk takes a look at the future of CAD and CAM in manufacturing and how the two technologies can be integrated effectively.

As CAD and CAM have been developing over the years, both technologies have undergone numerous changes from simple graphic design to 3D printing and VR.

With many lessons learnt and versions created, the industry now has a much more advanced offering. Thanks to improvements in visualisation, modelling, maintenance and data analytics, CAD and CAM now allow engineers to create products faster and with higher precision and quality than ever before. However, the software continues to develop and evolve even further with growing market demands for more customised and complex designs.

CAD and CAM integration

To address these new trends in the industry, we are now seeing CAM being integrated with CAD. Such integration is enabling manufacturers to have more control with additive manufacturing and programmable machines.

The integration of CAD and CAM helps designers and manufacturers unify and overlap stages of the making process: design, engineering, simulations and manufacturing. Designers can quickly iterate designs, perform simulations and create photorealistic renderings to better understand the product and make alterations. Engineers can then programme high-quality toolpaths to keep the production lines running smoothly.

This integration has simplified the production process for golf putter manufacturer, Sandflo Golf. Being able to 3D model putters in CAD enables the team to make small adjustments if needed before transferring the design into CAM software. The design informs the manufacturing toolpaths and generates a reliable code to run the part in the mill or lathe without having to keep a watchful eye, freeing up time for the manufacturer to focus on more creative work.

Streamlining the production process

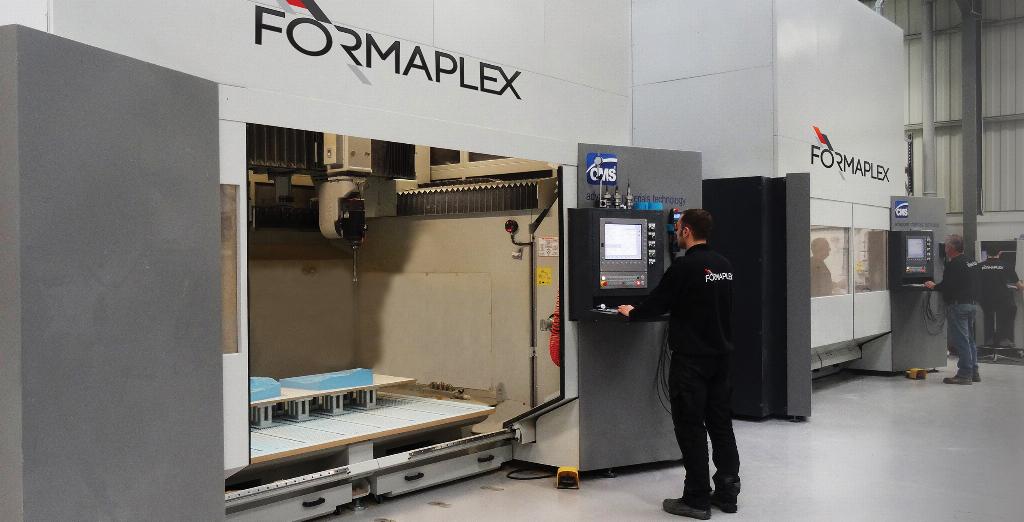

Such integration can allow manufacturers to create fully streamlined processes, from designing an assembly, component or object in CAD software to creating toolpaths for CNC machines. Aligning each process helps manufacturers to maintain quality, increase efficiencies and meet tight deadlines. A great example here is Formaplex, a manufacturer of injection mould tooling, composite tooling, thermoplastic and composite components. The demand for Formaplex’s services grew considerably due to its reputation for producing high quality tooling and components within extremely short lead-times.

To meet the customer demand, it needed the most agile machinery, tooling and design processes to support increased production levels. With the new integrated software, its machines were able to safely move around the material with ease, reducing machining times significantly. In addition, Formaplex can also review the data and design process for each component and tool to ensure compatibility with their tooling capability for ease of manufacture. As a result of combing several parts of software, Formaplex is now able to streamline the entire manufacturing process to achieve the best results.

Taking the future of manufacturing into VR

As augmented reality and virtual reality are coming of age, manufacturers have started uncovering the benefits of the technologies by integrating the tools into production. With the evolution of VR technology, manufacturers can now easily transfer their CAD models into a virtual environment for even further optimisation and development. Through VR goggles, they can see real-sized virtual prototypes of their designs, allowing them to explore detailed models. This can enable them to conduct quality checks and pre-empt possible issues before their concepts are brought to life with a physical prototype.

This is a technique that Hack Rod, the world’s first artificial intelligence-designed car, has used to visualise and make changes to a full-scale car model. However, the technology has also allowed the team to collaborate with design partners across the world to further refine the vehicle.

Eventually, such technology will allow engineers to move the parts of the object around and interact with the designed object to optimise it for the best possible design. Having an ability to easily demonstrate it to the client, make amends and transfer it to production via the integrated system will ensure that the process is working to its best potential. This will equip the manufacturers with the right tools and techniques to make much better design decisions for future products.

For manufacturing to succeed, it is imperative that hardware, materials, and software are tightly aligned. This blend of processes will help engineers to make more informed decisions and product alterations, streamline the production and improve efficiencies. This means that simply adopting technologies like VR is not enough. To make sure manufacturers keep up with the competition in the market, they need to ensure all of their processes are integrated, co-related and well connected to each other. Grasping this future of making things and using the most innovative technologies, will put manufacturers on the front foot and ensure they produce the best objects possible.

Autodesk www.autodesk.co.uk