Blum-Novotest’s demo room proves a major hit with customers

Customers interested in test driving Blum-Novotest’s range of products now have the opportunity to ‘try before they buy’.

Customers interested in test driving Blum-Novotest’s range of products now have the opportunity to ‘try before they buy’.

The company has invested in upgrading the Demonstration Room at its UK headquarters in Burton-upon-Trent to feature all of its technology, including the recently launched Digilog family.

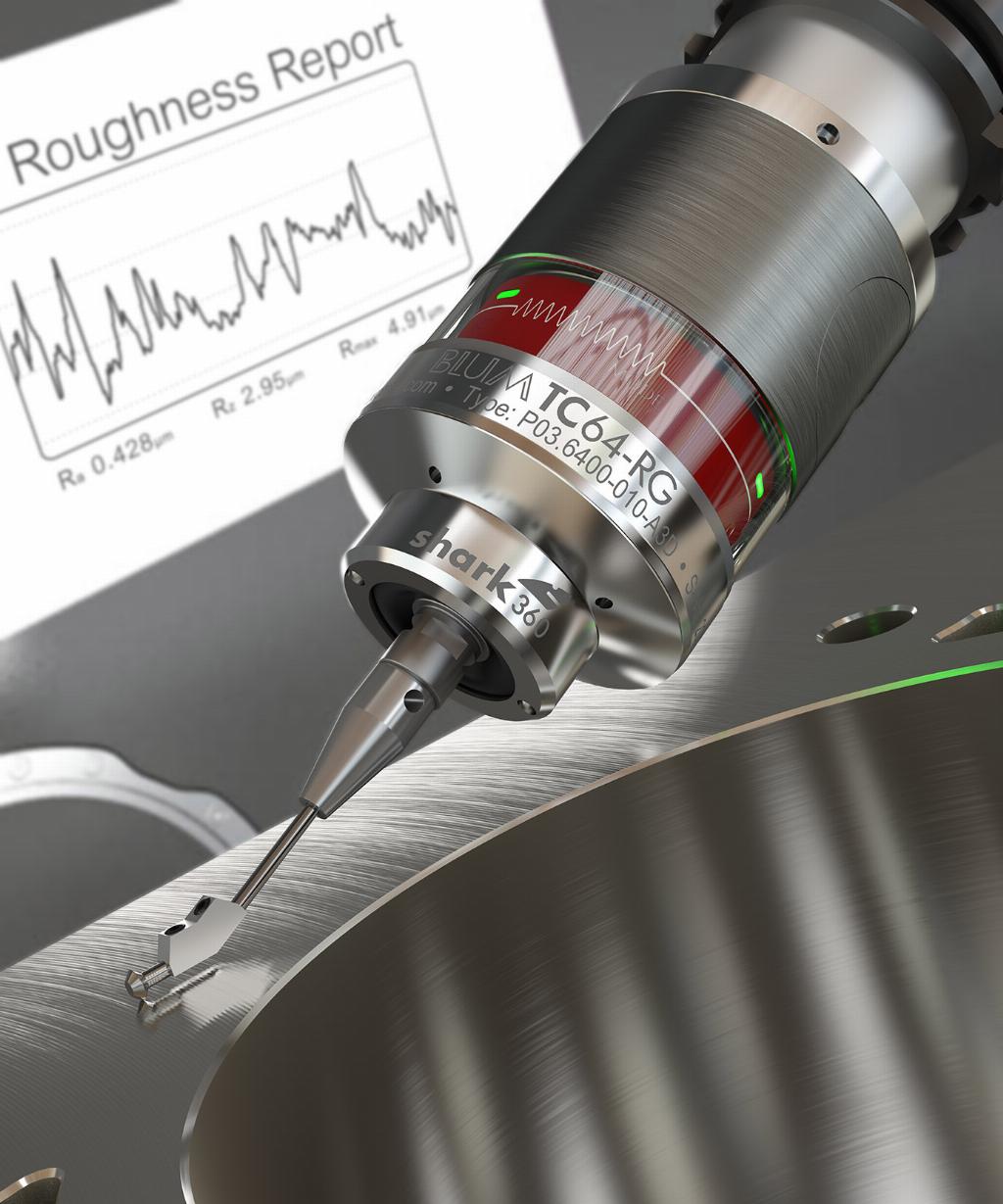

A Bridgeport GX710 vertical machining centre – fitted with Fanuc 0i control – is available for existing and potential clients to see real-time demonstrations of in-machine measurement, and roughness and bore gauges.

“The initial purpose of the machine was for the development of our UK engineers so they could quickly get up to speed with the new products and software being introduced,” explained Nathan Baulk, engineering manager.

“This means when we interact with customers we know exactly how the Blum technology can help their business and can offer fast installation, servicing and maintenance. However, we quickly realised we could use the facilities to give manufacturers the chance to see the performance of the products first-hand, before they invest.

“This has proven very popular and we have even had clients bringing their own parts up so they can witness the improvements in speed and accuracy on an actual production component. The confidence that then gives them to make the investment is huge.”

Blum-Novotest is embarking on an ambitious roll-out of new technology and products this year and has strengthened its team with the appointment of a dedicated technical sales engineer, Paul Hodgkinson.

Blum-Novotest www.blum-novotest.com