Right-first-time thanks to smart software

The acquisition of Bystronic fibre laser, press brake and software technology has enabled Holmfirth-based sheet metal design and engineering specialist, Allsops, to create a seamless cutting and bending production environment. PES reports.

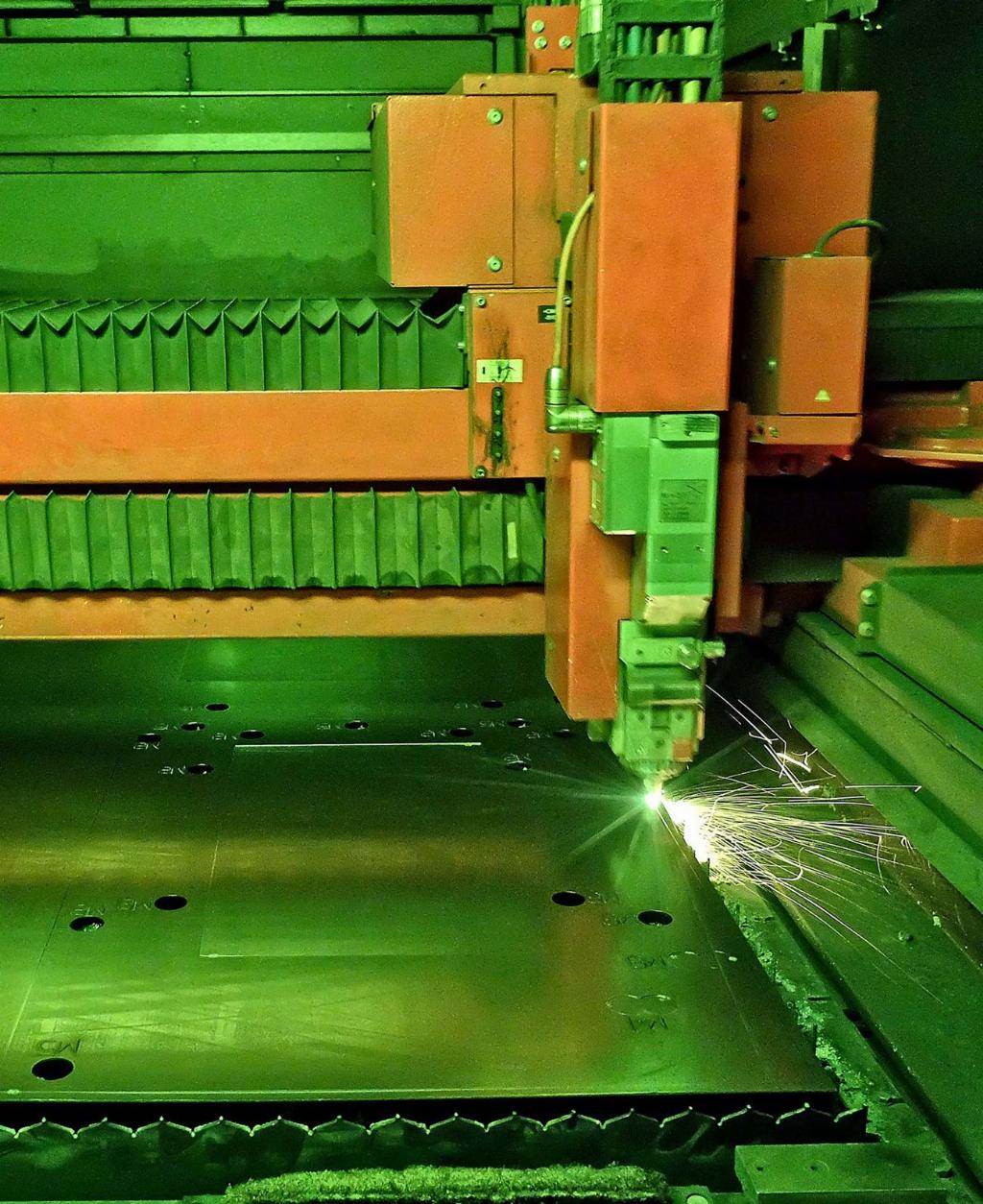

In recent years Allsops has progressed from CO₂ to fibre laser cutting, resulting in significant financial savings for the West Yorkshire company. Mild steel from 1.2 to 3mm thick is mainly processed and for these gauges – even up to 6mm – the production output from each of two Bystronic fibre laser machines is at least three times that of the previous CO₂ models they replaced, added to which running costs are much lower.

Furthermore, during 2018 the subcontractor upgraded its bending capability with the addition of two Xpert 40 Bystronic press brakes having a bending length of 1m and a stroke of 200mm. Raising the number of press brakes on site to 11, they provide a much more efficient platform for bending smaller parts than is possible using a 3m capacity machine, which necessarily has slower axis movements.

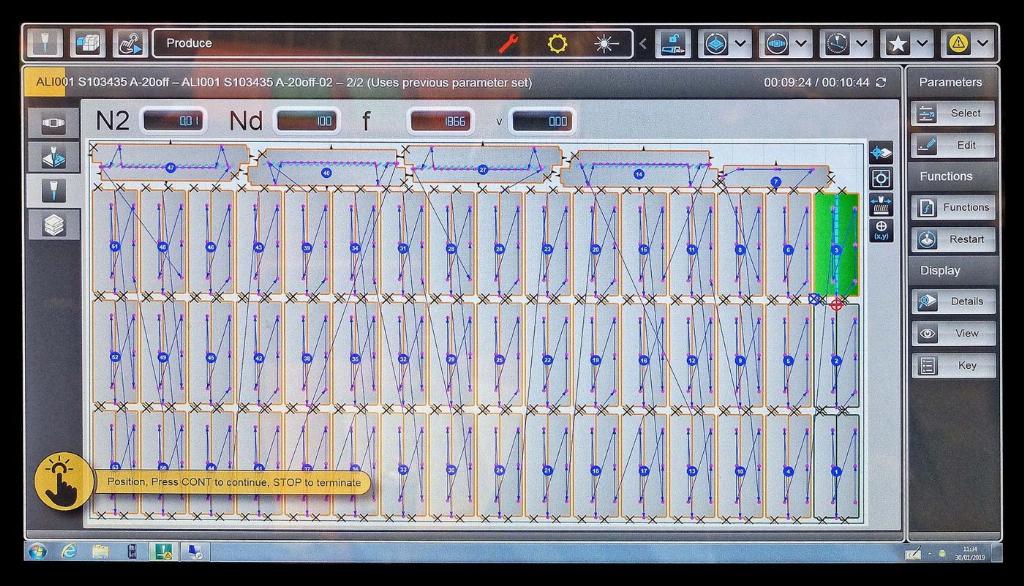

Further benefits come from Allsop's use of the Swiss manufacturer's BySoft 7 software to program both the fibre laser cutting machines and the new press brakes, resulting in seamless, rapid progression from cutting the blank to bending, guaranteeing the accuracy of the first-off part. This is invaluable for economy of production when dealing with prototypes and short runs. The software includes simulation of the bending sequence to identify any impending collisions.

Allsop's technical director Stephane Lericolais explains: "We previously used generic programming software for laser cutting and bending, but since 2010 we have standardised on BySoft 7. It imports our customers' 3D CAD models, flattens them and automatically generates programs offline for cutting the parts, nesting them optimally within a 3 x 1.5m sheet, and then bending them accurately.

"We know that the first part will be within tolerance whereas previously, when producing a prototype or starting a batch run, we would have to cut a blank, calculate the bend allowance, fold the part, check it for accuracy and have to do the same again perhaps once or twice before the job was right. All of this created expensive scrap and took much longer."

Handy bending

Not only is production able to start more quickly on the compact Xpert 40 press brakes, but the machines are also highly efficient, according to Allsop's production director, Lyndon Tyas.

He comments: "With these inherently fast bending cells, all of the upper and lower tooling is to hand in drawers on the left and right-hand sides of the machine and the operator can remain seated when loading them.

"Tool positions are automatically calculated as a part of the program and flashing LEDs on the front of the upper beam instruct the operator where to mount the tool segments.

"The ergonomic configuration means that setting up the machine is rapid, typically 15 minutes for a straightforward part. Accuracy is high – we easily hold ±0.5mm, more than good enough for most jobs and we can even halve that tolerance if required."

He also points out that there is space to hold cut blanks on one side of the machine and components that have been bent on the other. Another feature is the ByVision touchscreen control, which can be conveniently positioned to one side at the operator's eye level, or just above it centrally if preferred.

Allsops has been a customer of Bystronic and its acquired companies for more than 20 years and there is little sheet metal processing equipment on the Holmfirth site, apart from a bending line and a punch press, that have not been sourced from this supplier.

While thinner gauges of mild steel constitute a majority of the material going through the machines, plate up to 25mm thick is also cut as well as stainless steel and aluminium up to 30mm.

The subcontractor was an early adopter of CO₂ laser cutting, installing its first model back in 1995. Latterly there were two such machines on the shopfloor with a 4.4kW and 5.2kW laser source respectively. They were replaced in 2015 and 2016 by a BySprint Fiber and a ByStar Fiber, both of 6kW specification and of 3m by 1.5m sheet capacity.

The machines are supplied with material from ByTrans handling units that were formerly fitted to the CO₂ machines, enabling automated delivery of fresh sheets to the machines and return of laser profiled components for removal from their skeleton.

Allsop's is yet another good example of where fibre cutting has massively increased productivity compared with CO₂, in this case typically threefold. Managing director Rob Machon and his team had been keeping an eye on the advent of the technology and had watched the introduction of machines with 2, 3 and then 4kW of fibre laser power, but decided to wait until 6kW became available before making the first investment.

An end to 24/7

If the BySprint model was a revelation in terms of increased throughput, the ByStar installed the following year raised performance significantly further. Due to faster axis movements and higher dynamics compared with the earlier fibre machine, some sheets are processed 30% faster if components are complex, while for the simplest jobs there is still an improvement of nearly 10%.

Together, the machines are so productive that to achieve the required throughput, it is no longer necessary to run the factory 24/7, leading to significant labour cost savings. Currently, only a night shift is needed four days per week and there is no longer a necessity for weekend working.

At the end of Friday afternoon, the two ByTrans are loaded with material, which provides both machines with a couple of hours' lights-out running for processing the following Monday morning.

Mr Lericolais advises that further savings result from there no longer being a need for any laser gas or beam purging gas, while assist gas usage per cut component is 37% less.

Additionally, electricity bills have reduced by a similar amount; unsurprising as CO₂ technology requires 98kW of input power to generate 6kW of laser power at the cutting nozzle.

Allsops www.allsops.co.uk

Bystronic www.bystronic.com