CAM revolution

SolidCAM UK will be verifying its claim of being one of the most powerful CAM systems in the world from its stand 348 in Hall 17 at MACH 2024.

Owing to a core strategy of focusing on integrating with the leading 3D CAD systems, SolidWorks, Autodesk Inventor and Solid Edge, which has created major growth as well as establishing SolidCAM as a leader in integrated CAM, the company vows to inspire and impress attendees with its latest technological advancements.

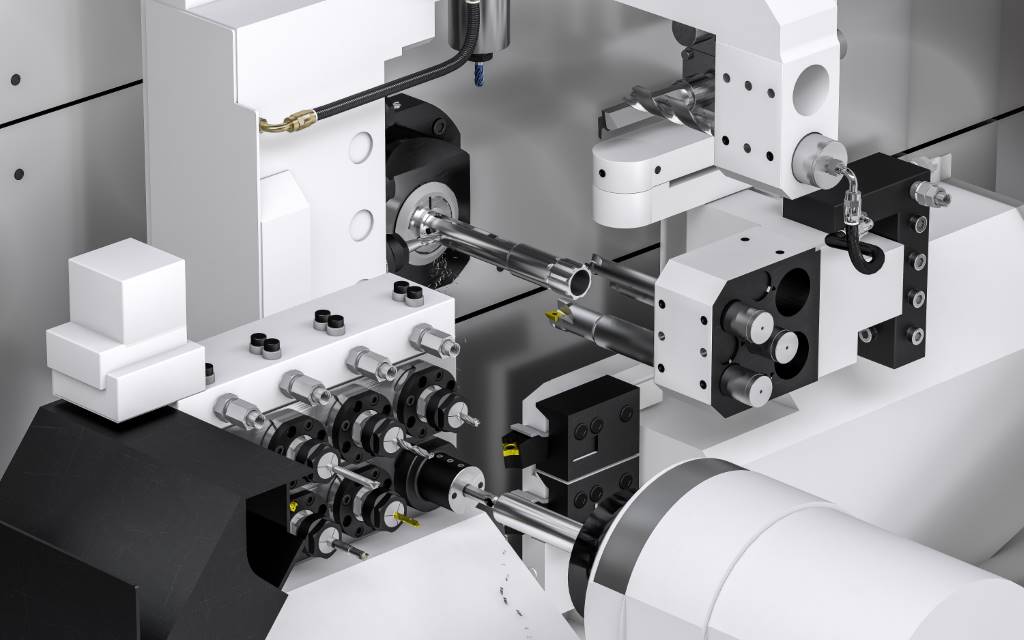

SolidCAM UK will be showcasing its scalable software which supports all milling and turning functionality, highlighting its powerful support for advanced mill-turn machines including multi-turret, multi-spindle and sliding head (Swiss-type) plus multi-channel synchronisation.

It claims the days of low productivity, modest ROI forecasts and dependence on outdated single operation machines are numbered. It also claims SolidCAM is a driving force behind the sliding head revolution, where manufacturing companies will be optimally positioned for the future with these machines that are more complex, risky, and unproductive to program manually on the controller.

There is no limit to the number of axes SolidCAM can control and synchronise with mill/turn applications. This provides companies with a cost-effective way to produce small, complex and precise parts in large quantities. The UK & Ireland reseller advocates that its software allows companies to get the most out of their high-end multi-tasking machines and will be on hand at MACH to demonstrate why.

CAM solutions for efficient and profitable programming fully integrated inside CAD systems, with full toolpath associativity, including easy to use technology with fast program creation will be showcased on the stand.

In today's world of manufacturing, every minute counts and every CNC machine must be utilised to the maximum. According to the developer, the company’s flagship SolidCAM iMachining technology, which is particularly effective on hard and difficult to machine materials such as Inconel and titanium, offers cycle time savings of 70% and more compared to traditional machining solutions, as well as increased tool life by five times or more.

Gordon Drysdale, managing director, SolidCAM UK comments: “AT MACH, visitors can discover how to benefit from the most tested and proven powerful simultaneous 5-axis machining toolpaths in the industry, with a user-friendly interface, collision checking and the most advanced control over all aspects of the toolpath. This includes special strategies and features such as Barrel Cutting, Swarf Machining, Rotary Machining, Multi-Blade Machining, Edge Breaking, Edge Trimming, Multi-Axis Machining, and Port Machining.

“We make bold claims that SolidCAM is the best-in-class CAM solution that’s easiest to use, with the shortest learning curve, and technology that can save 70% – or even as high as 90% - in machining time on even the most complex mill/turn and Swiss-type CNC machines,” he adds.

“At MACH we’ll demonstrate the full power of SolidCAM and we look forward to welcoming existing and prospective customers to our stand, helping them to advance their manufacturing processes and taking them to an entirely new level of CNC performance.

“Visitors will also discover that the ideal CAM solution not only involves the best software but also the best service levels. SolidCAM UK’s technical and post-processor support is praised by all of our customers and is a core part of our business.”

SolidCAM

www.solidcamuk.com

Hall 17, Stand 348