Good vibrations for turning – MACH 2022

Citizen Machinery will be exhibiting both sliding head and fixed head technology at this year’s MACH.

The company will also be will be celebrating the fifth anniversary of its innovative low frequency vibration (LFV) chip-breaking software, https://cmj.citizen.co.jp/english/product/lfv which forms part of the operating system in the controls on some of the manufacturer's sliding and fixed head mill-turn centres.

Essentially LFV means the size of chips from the workpiece can be controlled, meaning stringy swarf is a thing of the past, even when machining difficult to chip materials like stainless steel, aluminium, copper and plastics.

The need for manual swarf clearance is therefore avoided, raising productivity and unattended running time, while the risk of damaging the workpiece and tool is removed leading to longer tool life and improved surface finish due to better coolant penetration at the cutting edge.

There will be five Cincom machines on show at MACH equipped with LFV along with a Miyano fixed head lathe featuring the technology. A total of 12 turning machines will be demonstrated under power, including an automated production cell with integrated loading and unloading.

Sliding head lathes

From the Citizen sliding head machine range (making its world debut) will be the new 20mm bar capacity Cincom L20-XIIB5LFV. The series-5 Cincom M32-VIIILFV will also appear for the first time at a MACH show.

Additionally, a Cincom D25-VIILFV will be exhibited for the first time with the LFV proprietary chip-breaking software. As on many other sliding head lathes manufactured by Citizen, the user has the advantage of being able to remove the guide bush for more economical material usage when producing shorter components up to typically 2.5 times the bar diameter.

Also at MACH will be the Cincom L20, Citizen's bestselling sliding head lathe, that has been upgraded to simultaneous 5-axis control via the improved, super-fast M850VM CNC with 15" touchscreen. The new L20-XIIB5LFV allows multi-axis programming for superimposed machining with up to three tools in cut at the same time. It makes the machining of complex parts faster and easier and improves process stability.

Lathe with lasers

Launched in mid-2019, the Cincom 8-axis L32â€ÂÂXLFV will be on show, without the optional LFV software but with the addition of high-speed, in-cycle laser cutting. The technology, which was originally developed for efficient production of apertures in thin-wall stents, is capable of fulfilling a wide variety of additional operations when machining tubular stock or bar after it has been drilled longitudinally.

The development provides the option of in-cycle production of burr-free holes as small as 0.2mm diameter and features such as spiral cuts with a 0.025mm kerf. Consistent and accurate radii of less than 0.1mm in the corners of slots can be achieved without risk of tool wear or breakage and at a far faster rate than is achievable by a separate EDM process.

The new flagship series-5 M32-VIIILFV sliding head lathe with Mitsubishi M850W control will occupy a prominent position on the Citizen stand. The 10-axis machine has undergone a fundamental makeover and is considerably more robust than its predecessor, with larger and more rigid ballscrews and a bed that is 500kg heavier, bringing the total installed weight to 4.3 tonnes.

Fixed head innovations

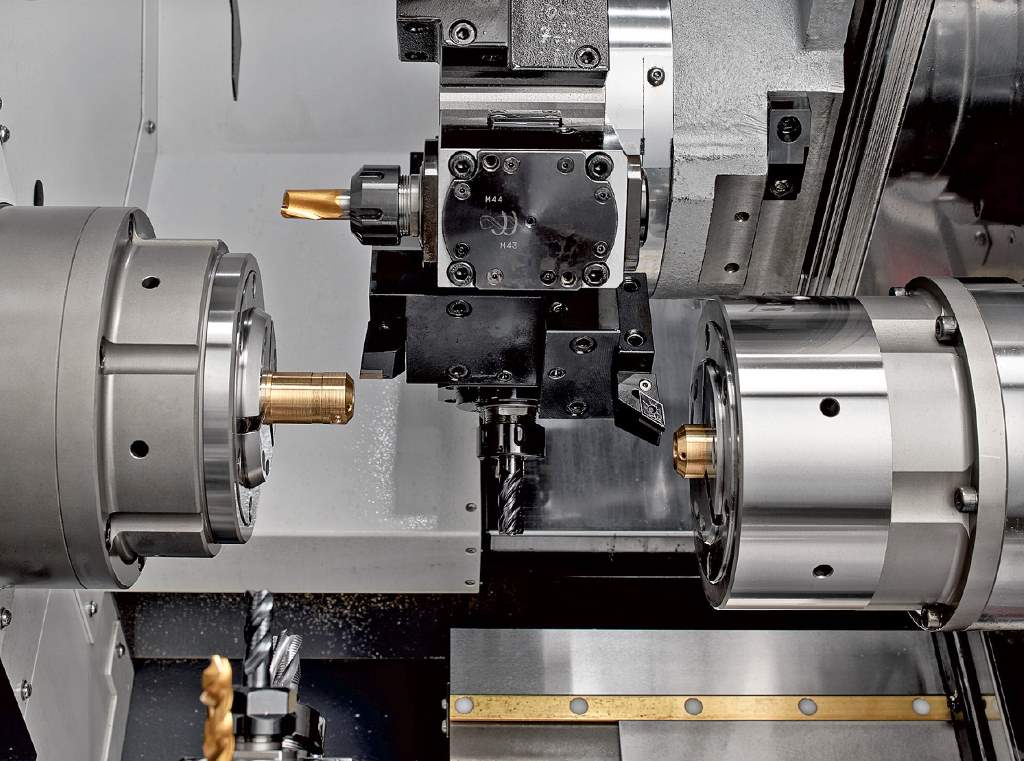

Machines on show from the Miyano fixed head stable on the Citizen stand, include the BNEâ€ÂÂ65MYY which has been redesigned to offer more power and flexibility and been fitted with the latest Mitsubishi 800-series touchscreen control. Consequently, the machine is Citizen's first 65mm capacity lathe to offer superimposed machining, which allows three tools to be in cut together under simultaneous 5-axis control for elevated levels of productivity.

Complex components up to 65mm diameter may be turned and milled from bar on the new Miyano BNE65-MYY 10-axis fixed head lathe. Equipped with two Y-axis turrets, one positioned above and the other below the centreline of the twin-opposed spindles, considerable flexibility is provided for balancing front and back working cycles.

The eight-tonne machine was introduced in the autumn of 2020 and is therefore making a first appearance at MACH this year.

Cohesive control

Making another appearance to illustrate automated chucking will be the twin-spindle Miyano GN-3200W equipped with a high-speed loader capable of achieving high levels of productivity. The compact, rigid, thermally symmetrical machine offers a wide choice of infeed/outfeed devices, single or double high-speed gantry loaders, and transfer and turnover units, making the machine ideal for automated production.

The largest bar capacity CNC lathe in the Citizen Machinery product portfolio is the new 12-axis Miyano ABX-64THY, a fixed head model also launched in the autumn of 2020 and therefore also new to the MACH show.

It has twin-opposed C-axis spindles and three Y-axis turrets moving over hand-scraped box ways, providing maximum rigidity. Originally designed for mill-turning parts from 64mm diameter stock, the lathe can now be uprated for continuous, automated, unattended production of components from bar up to 80mm diameter. Maximum billet size when chucking is 165mm diameter.

Citizen Machinery UK

www.citizenmachinery.co.uk

Hall 20, Stand 150