Driving the dream

Vladislav Belyakov, CEO of Box39, St. Petersburg, Russia, has long been driven by the idea of putting together a dream motorcycle.

After researching the motorcycle tuning market in the Russian Federation, he discovered that most components for custom bikes had to be imported which drove up costs and lead-times. The problem was there were very few companies in the country that had the CNC equipment needed to product high quality custom components at a reasonable cost.

“Marketing research told us that local custom motorcycle products were made by companies that could not meet high tolerance requirements,” Mr Belyakov says, “and in most cases, these companies had to perform time-consuming and expensive manual finishing operations. They were also often unable to produce complex parts with irregular shapes such as more than one undercut, surface openings and transitions in different planes.”

Mr Belyakov felt that an opportunity existed for a company to apply modern manufacturing methods to custom motorcycle components: “I took a big risk in making a career switch from financial services to motorcycle parts manufacturing in 2011,” he explains. “Our first production facility was a rental garage and we designed and put our first product into production within six months of opening our doors on a very tight budget."

Since then, Box39 has developed three more products and also developed a thriving business in tuning motorcycles, which involves installation of accessories and painting to change the concept, appearance and performance of a stock model into a custom bike. The business has grown rapidly.

"Last year, we decided to automate our production facility and purchase our first CNC machine,” Mr Belyakov affirms. “It allowed us not only to improve the quality and efficiency of producing our existing products but also makes it possible in the future for us to develop parts with more complex geometries that can’t be produced by conventional methods.

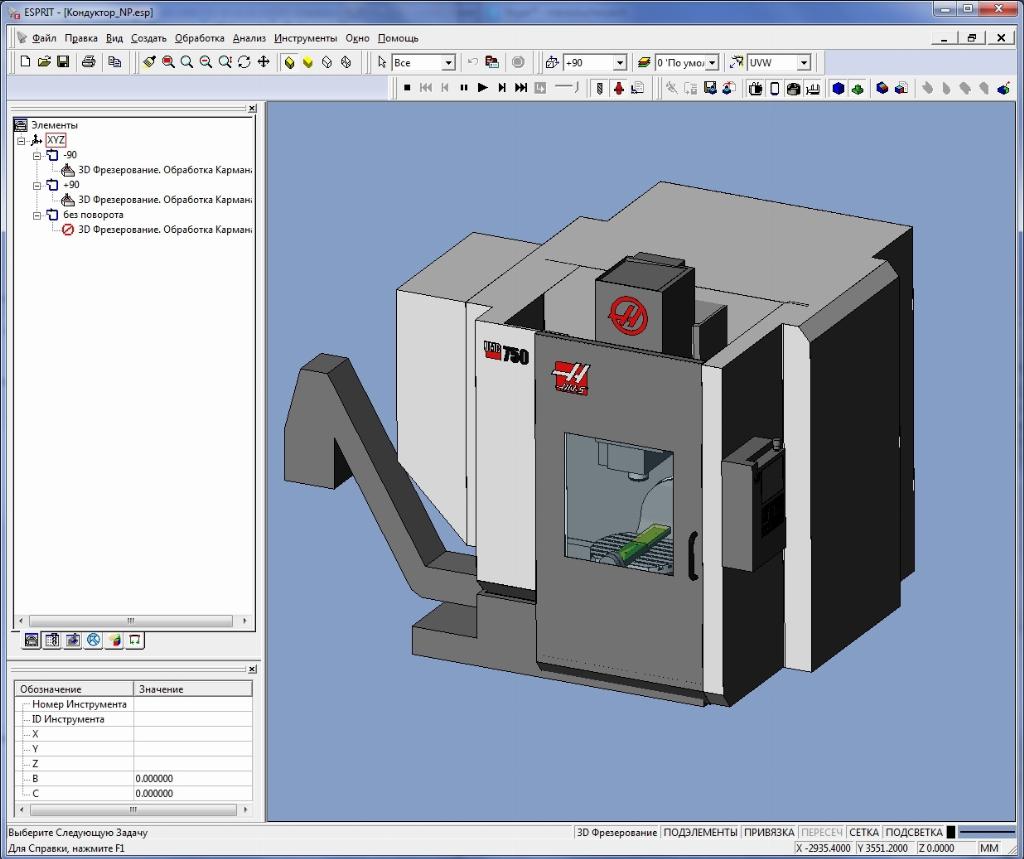

“After spending a long time evaluating different machine tools, we purchased the Haas UMC-750 5-axis universal machining centre. We believe that using modern equipment and software in the production cycle will reduce the cost and delivery time and also improve the quality and artistic value of the product. This in turn will help to expand the overall market for custom motorcycles.”

Multi-axis machining reduces set-up time and increases processing precision of complex parts that are machined at multiple angles. The Haas UMC-750 is a versatile 5-axis universal machining centre with 762mm x 508mm x 508mm axis travel and an integrated dual-axis trunnion table. The machine is equipped with an inline direct-drive 40 taper spindle (8,100 or 12,000rpm) and comes standard with a 40+1 tool side-mount tool changer. The trunnion allows manufacturers to orient parts to almost any angle for five-sided machining or provide simultaneous 5-axis motion for contouring and complex machining. The machine provides +110 and -35° of tilt and 360° of rotation for excellent tool clearance and large part capacity.

Igor Bystrov, who is a designer and technologist at Box39 recalls the process of choosing CAM software: "After we ordered the machine, cutting tools, and equipment, we started to search for the optimal CAM package. We looked for software capable of programming 3-axis and 5-axis milling that is compatible with our SolidWorks CAD software at a reasonable price – and obviously we needed a post-processor for our CNC machine.

“Only two CAM software packages offered in Russia met these requirements. We selected Esprit by DP Technology because it includes a Haas-certified post processor and a UMC-750 virtual model. Another factor in our decision is the strong training and technical support provided by DP Technology in Russia.”

In late 2014, Box39 received its Esprit licenses. “We had some experience with our CAD system, but we were not familiar with G-codes and M-codes nor with CAM software,” Mr Belyakov recalls. “Our engineers attended a weeklong training course and immediately began creating CNC programs for the 5-axis machine. We were able to get up and running almost immediately because the post-processor worked perfectly from the start. Since that point we have produced many CNC programs and continue to increase our programming skills. Today, we can offer our customers dramatic improvements in quality and productivity relative to other companies in the custom motorcycle components market.”

The Box39 team has set ambitious goal of bringing the latest CNC manufacturing methods to custom motorcycle component manufacturing. “The combination of a modern CNC machine and powerful CAM software is helping us to create beautiful and powerful bikes,” Mr Belyakov concludes.

In the UK, sales and support for Esprit is provided by Mid-Glamorgan-based CAM Supplies & Services, and Scotcam located in Wishaw, Lanarkshire.

DP Technology Europe www.espritcam.fr