German automotive manufacturer is also a Heller beta test site

With the accelerating emergence of electromobility and hybrid technology, the components machined by German firm Stöferle Automotive GmbH are becoming more and more complex, while dimensional accuracy and surface finish requirements are steadily increasing.

So in 2019, the Laupheim-based company started looking for high quality horizontal machining centres (HMCs) on which to produce mild hybrid car components in diameters ranging from 240 to 320mm with fits between H6 and H7.

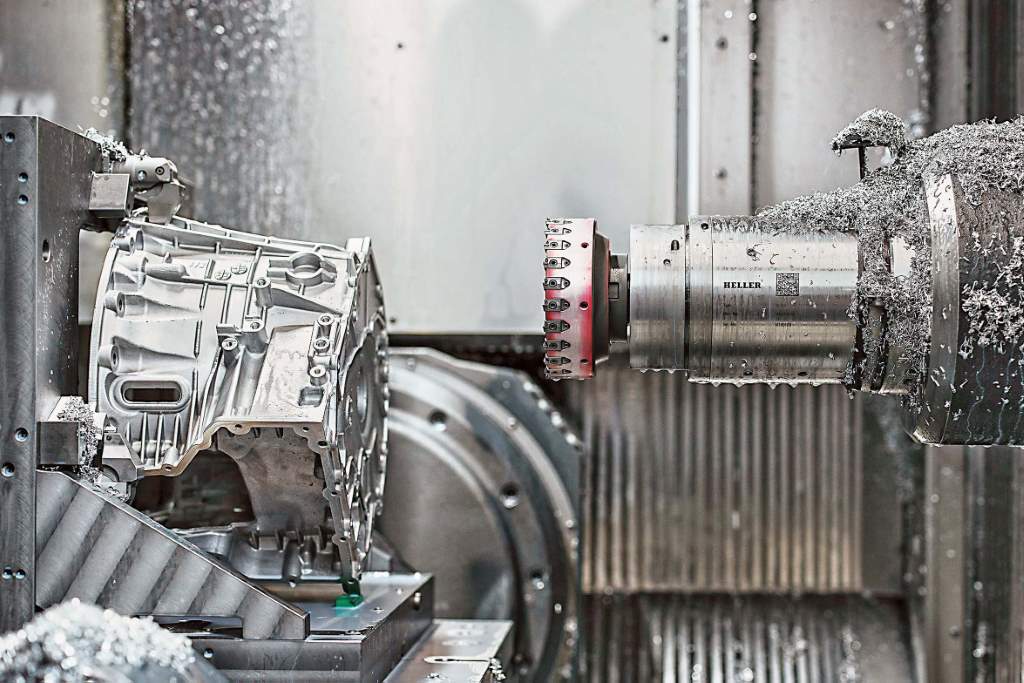

After evaluating numerous machines on the market, Stöferle decided to invest in two second-generation HF 5500 5-axis machining centres from Heller, located in nearby Nürtingen. The machines were installed well in advance of their official launch date, as the Laupheim firm is a long-time Heller user and a beta test site for its machines.

They were integrated into a production line operating three shifts, seven days a week, and produce up to 350,000 components annually. In addition, Stöferle has bought two H 2000 4-axis models from Heller's fourth generation H-series.

Joint managing director Erich Stöferle says: "We perform real endurance tests on Heller machines lasting years. We run them to the maximum, operating at a small percentage below the performance limits specified by the manufacturer.

"If the maximum weight of a milling cutter is specified as 16kg for example, we go up to 15.5kg. We use a 160mm diameter milling cutter at 15,000rpm, which may not be a problem in single part manufacture but we produce continuously over three shifts.

"Another aspect of the tests is that the two HF 5500s are part of a manufacturing line comprising five or six machines. As annual production quantity has been set at 350,000 pieces, a high level of reliability is crucial.

"Our tests show that Heller's aim of delivering machines capable of high productivity and precision day in day out has again been implemented in the new-generation HF-series."

The engineers in Laupheim believe that Heller's new HSU inline spindles produced in-house provide clear advantages over earlier versions. The latest spindles are much more rigid, lowering vibration, and the design allows rapid, cost-effective replacement. Stöferle opted for SC (speed cutting) spindles rated at 18,000rpm and 103Nm torque.

Vibration is also reduced by the construction of the HF-series, which features a shorter distance from spindle nose to the centre of the B-axis rotary table, allowing shorter tools to be used and often avoiding the need for extensions. The machining centres provide impressive precision. Large components are machined within 20µm parallelism and have a high quality surface finish.

Stöferle also carried out field tests on the fourth generation of Heller's H-series of 4-axis HMCs. Starting in February 2020, a year before their launch, a pair of H 2000 machines was used for large volume production and continue to work around the clock.

The other managing director Katja Stöferle adds: "This was a logical consequence. We operate more than 20 machines in this series and have reliably manufactured over a million components on quite a few of them without major repairs. We had one H 2000 that ran for 15 years with the same ballscrew drives.

"For producing transmission components in batch sizes of 250,000 pieces per year, machine stability, the quality of the drives and chip disposal efficiency all have to be right. In short, these are our best machines."

Electromobility increases requirements not only in terms of component accuracy but also batch size so Stöferle is constantly looking for ways to reduce cycle times. In this regard, it is notable that Heller has improved the dynamics of the latest H-series of HMCs, measurably reducing the chip-to-chip time for some components produced in Laupheim.

Heller Machine Tools

https://uk.heller.biz