Gordon Murray moves supercar production to new HQ

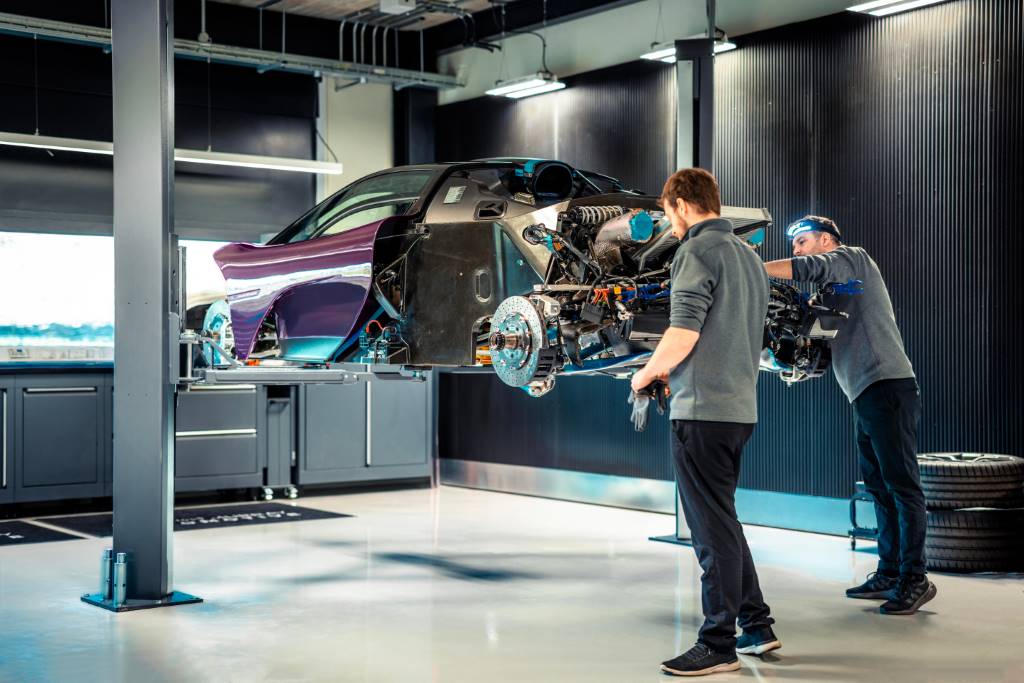

British supercar manufacturer Gordon Murray Automotive (GMA) has moved production of the T.50 to the company’s newly built group headquarters at Highams Park, Surrey.

The new site has already taken over manufacturing of the GMA T.50 supercar from its previous production facility at Dunsfold Park. T.50 production will benefit from a wealth of efficiencies, while enabling the business to streamline carbon fibre monocoque production for T.33 prototypes and future models at Dunsfold Park.

Used for development, testing and homologation-related crash testing, the monocoques will now be produced on-site, accelerating the supercar’s pre-production processes.

Building the new Gordon Murray Group headquarters at Highams Park near the village of Windlesham saw investment of more than £50m, and the creation of a broad range of specialised job roles to support full scale production. The new campus will be the group’s global headquarters – home to a purpose-built 4,300m2 Vehicle Production Centre, and the Gordon Murray Heritage collection.

The site also features a specially-designed Vehicle Dynamics Test Road, used for final validation and pre-delivery checks of new GMA supercars – all set in 54 acres of beautiful English parkland. For customers opting to take delivery of their cars from Highams Park, the new HQ offers the ideal setting at its dedicated Driving Perfection Customer Centre where owners can specify, set-up, and take delivery of their GMA supercar.

Phillip Lee, Gordon Murray Group CEO, commented: “The new Gordon Murray Automotive HQ at Highams Park represents a significant investment for the business and is a statement of intent for the company’s future. It is extremely satisfying that we’re able to continue T.50 manufacturing at the new site, while also streamlining production of T.33 development prototypes.”

Following the move to Highams Park, where all future GMA models will be produced, the company is on course to complete all 100 exclusive T.50 customer cars. The build of the 25 track-only T.50s Niki Lauda models will follow the completion of the T.50 run. Next, the production team will transfer to building the T.33 coupe, before that supercar’s open-top sibling – the T.33 Spider – enters the Highams Park Vehicle Production Centre.

The move to the new HQ will bring significant manufacturing efficiencies. The purpose-built site consolidates logistics, parts supply, and testing, while supercar production teams benefit from the latest technologies and optimised production layout, boosting efficiency, cross-team collaboration, and production quality.

Mofid Elkemiri, Gordon Murray Automotive CEO, added: “Moving production of our T.33 experimental prototype monocoques into the vacated Dunsfold Park facility accelerates the programme and boosts efficiencies significantly. We are already making excellent progress with T.33 development with our first three mule cars undergoing intensive early testing. The move means we’ll soon be at the stage to share details about the prototype with customers and fans around the world.”

In total, GMA will build more than 27 prototype versions of the T.33 coupe and Spider for a combination of pre-production testing and development activities including chassis dynamics, aerodynamics, durability, performance, emissions, crash testing, and certification. The car will be fully homologated for all major markets including Europe and the United States. As part of the development, the team will perform more than 30 different crash tests with prototype vehicles.

Gordon Murray Automotive

www.gordonmurrayautomotive.com