Grob extends 5-axis portfolio with new compact machine

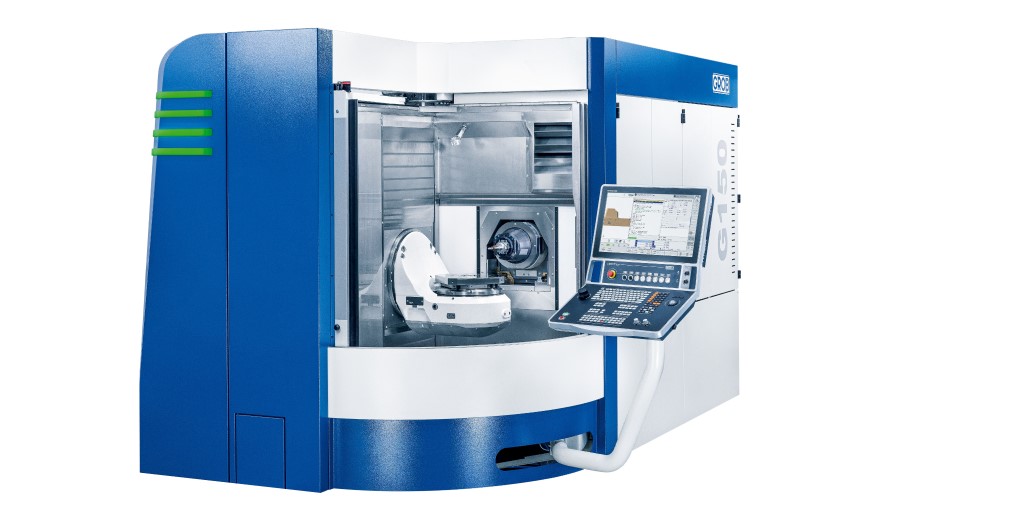

Due to its compact size and impressive specification, the new G150 5-axis horizontal machining centre from Grob has been developed with the medical sector in mind.

Showcased at the recent Global Industrie in Lyon, the MECSPE in Bologna, and MetalMadrid in Spain , the G150 is the smallest machine in Grob’s 5-axis portfolio and will complement its existing G350, G550 and G750 models.

“The development of the G150 was predominantly customer driven,” reveals Grob UK’s area sales manager Carl Downing. “A number of customers, particularly in the medical industry, considered the G350 a little too large for their needs. The G150 from a technical perspective has all the features of its larger stablemates, but comes in a compact package with a smaller working envelope. Nothing has been sacrificed in terms of specification.”

And on the subject of specification and design, Mr Downing references Grob’s ‘tunnel’ tool change concept’ which is an integral feature of all Grob 5-axis machines: “Basically the tool change process takes place away from the working envelope, optimising the machining space available,” he explains.

“We believe this concept is unique in the marketplace; the tool changer itself is located at the rear of the machine, allowing the largest possible component – even when using very long tools – to be machined within the work area without risk of collision.”

A universal machine such as the G150 will no doubt have a multitude of uses. Medical manufacturing is a target market for the machine, but Grob has also enjoyed significant successes in a wide range of other industries such as aerospace, energy, automotive and mould and die.

Grob has never had a showroom in the UK but that all looks set to change with a new facility planned for the end of 2022/beginning of 2023. Until then, customers can get up close and personal with the company’s entire machine tool range, software, and automation systems at its headquarters in Mindelheim, Germany.

“We have also established close partnerships with leading tooling manufacturers Seco, SGS, CIS and Guhring in the UK with machines installed at their respective facilities for demonstrations and process optimisation purposes,” Mr Downing adds. “This works really well for our customers and it’s an arrangement that we’ll probably continue with, even after the new showroom is open for business in 18 months’ time.”

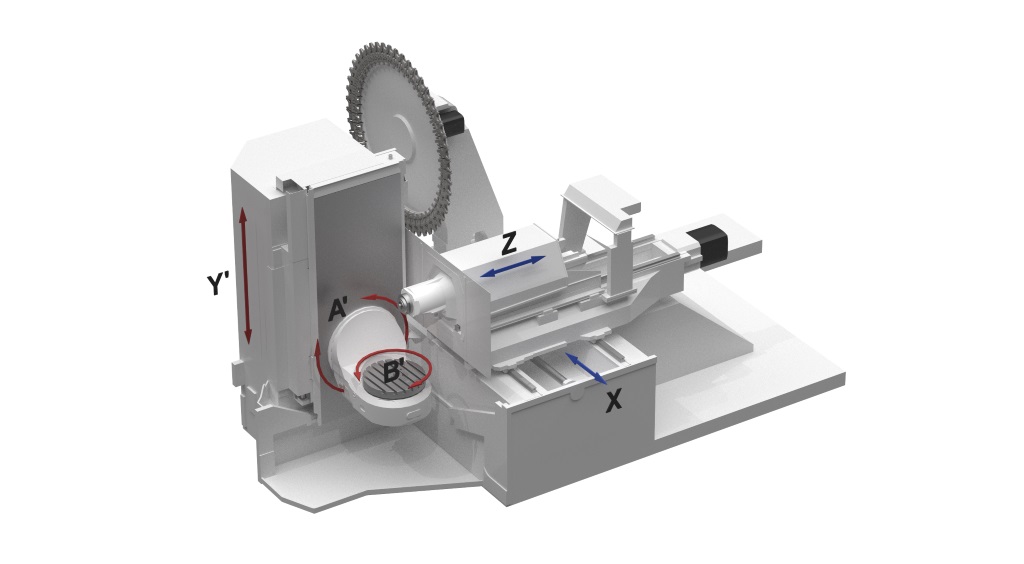

According to Jonaz Diez, Grob area sales manager in Germany, the G150’s standout features are its build quality, range of features and compact footprint with excellent process reliability. An innovative axis concept allows for a 580mm contour diameter and a 359° A-axis swivel range. The machine comes with a 320mm x 320mm pallet.

“Accuracy was a top priority in the development of the G150 with a contour accuracy of ±5µm on a reference workpiece,” he explains. “This was achieved by optimising the cooling concept and integrating drive simulation into the development process enabling five-sided machining in a single setup.

“It can accommodate a range of workpiece sizes using multiple setups and due to the variety of available options, the G150 is not only ideal for light machining applications, but also for heavy-duty cutting, offering 206Nm of torque with extreme stability. This is reflected in the performance of the machine: some of our customers are reporting up to 30% increases in productivity and 25% longer tool life.”

The machine's warm-up cycle is individually adaptable to the application in hand. The G150 detects when it can start the cycle and when it can end based on geometry parameters. If recalibration is required, the calibration software notifies the operator accordingly. In combination with a pallet storage system, calibration can be initiated automatically.

An important foundation for the success of the G-series is the combination of ergonomics with automation making it suitable for a job shop environment as well as for series production. In combination with a pallet storage system, the machine can be used for prototypes in the day shift and then for series production at night, for example.

Automation options include a pallet changer, the PSS-R rotary pallet storage system or the PSS-L linear pallet variant. New additions to the modular option system are the HSK E40 spindle with up to 42,000rpm and a compact table with central clamping.

As with all Grob machines, the specification of the G150 leaves nothing to chance. XYZ travels are 450, 670 and 665mm respectively with 50/40/60m/minute rapids, positional accuracy is an impressive 0.006mm in all axes and the 380mm diameter table can accommodate loads of 250kg without pallet changer and 220kg with. Machine weight is 14,600kg standalone and 15,400kg with pallet changer.

Construction wise, the horizontal spindle position permits a long Z-travel path and efficient chip evacuation. The three linear and two rotary axes permit five-sided machining as well as 5-axis simultaneous interpolation. The axis configuration also allows overhead machining and optimum accessibility.

The G150s drive train is courtesy of two symmetrically arranged ballscrews and a weight compensation function in the Y-axis. Torque motors in the A- and B-axes ensure the dynamic and wear-free machining of parts.

The arrangement of the three linear axes minimises the distance between the guides and the machining point (TCP), which adds to the G150s overall stability.

Grob Machine Tools UK

www.grobgroup.com/en/