Optimised toolpaths for medical components

Open Mind Technologies now offers hyperMILL Medical Solutions for companies that handle demanding machining tasks in that industry.

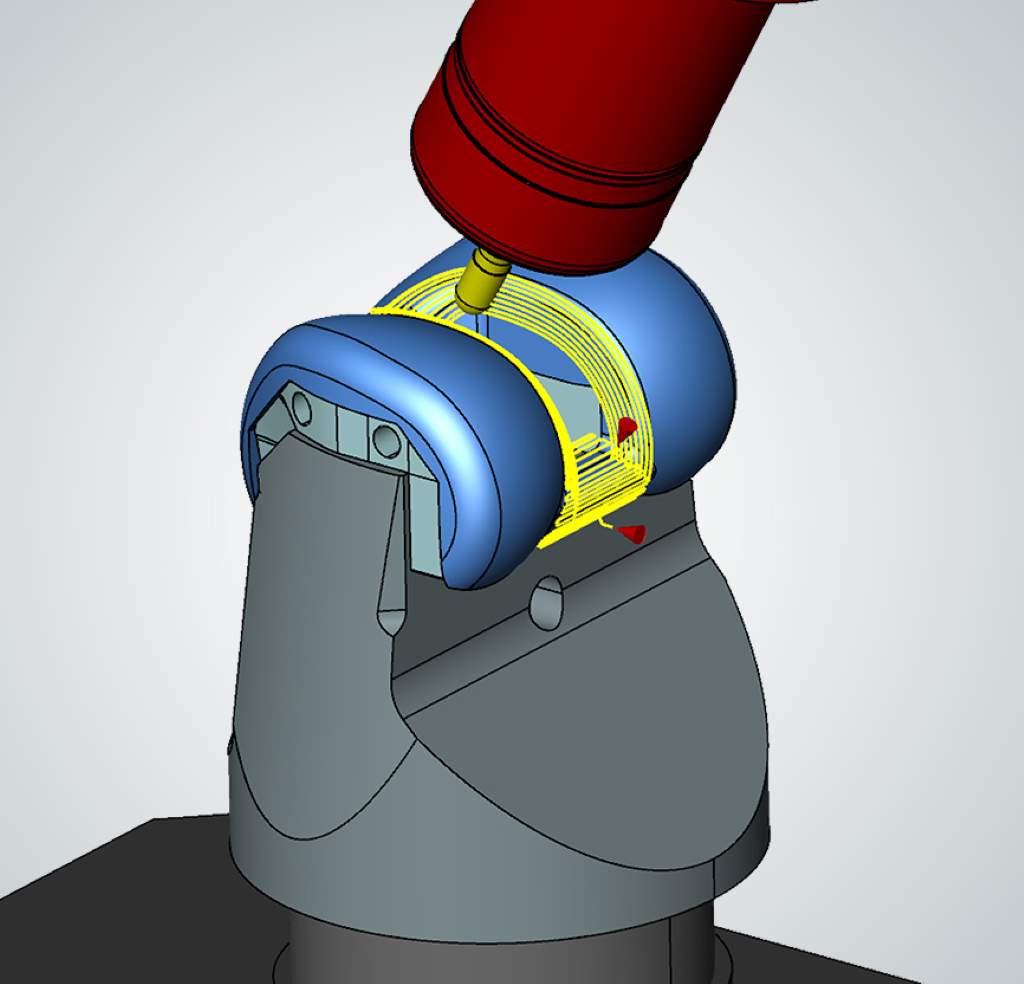

Manufacturers of implants and bone plates in various standard sizes can benefit from automated CAM programming. Optimised toolpaths protect machines and tools, enable safe and efficient processes, and ensure high surface qualities.

Despite the diverse range of shapes and materials used in the sector, what most machining tasks have in common is a high level of complexity. hyperMILL has made a name for itself in programming efficient toolpaths for implants and other medical engineering products.

When it comes to producing high-quality surfaces with minimum need for finishing, Open Mind offers optimised finishing strategies that ensure perfect transitions between different sections.

A key feature of hyperMILL Medical Solutions is its powerful tool database with interfaces to catalogues from well-known tool manufacturers. Special tools can also be mapped in the tool database. Materials suitable for medical applications – titanium, cobalt-chromium alloys or temperature-sensitive plastics such as UHMWPE – are usually difficult to machine so it’s important to select suitable tools and cutting parameters and to account for these when programming the toolpaths with 2.5D, 3D or 5-axis strategies.

hyperMILL Medical Solutions is ideal when it comes to accommodating the need for patient-specific adjustments, the various standard sizes and part families, as well as the associated automation of NC code generation. The hyperMILL Automation Center allows users to define and standardise CAD/CAM processes. This includes the specification of steps for data preparation and programming, right up to simulation and NC program generation.

Once this has been done, the process is deployed and carried out on new components making it possible to automatically prepare and programme machining projects. Automation can be learned easily by any CAM user but Open Mind also offers support for the automation of CAD/CAM processes.

Open Mind

www.openmind-tech.com