Innovative auto-adjustable fine boring head debuts at EMO

ActiveEdge Apex, the latest fully automated fine boring innovation from Rigibore, shifts the concept of what is expected from a fine boring head as the perfect solution for accurate machining of small bores.

Apex delivers new levels of control in setting and maintaining critical tolerances through a fully automated process. Making use of Rigibore’s ActiveEdge technology, Rigibore says Apex is a world-first in terms of fully integrated, automatically adjustable fine boring heads, delivering precision performance on bores ranging from 0.25mm – 26mm diameter.

Rigibore will unveil the Apex system at this year’s EMO show in Hannover, held from September 16-21, which has a theme of ‘Smart Technology Driving Tomorrow’s Production’, therefore providing the perfect opportunity to showcase this solution.

With manufacturing industry’s ever higher expectations regarding production of high-value components, Apex’s auto-compensating system creates significant and lasting benefits in reducing machine downtime, improved part quality and operator safety. Of greater significance, however, is the ability to consistently meet and maintain critical tolerances, while at the same time eliminating the risk of part scrap.

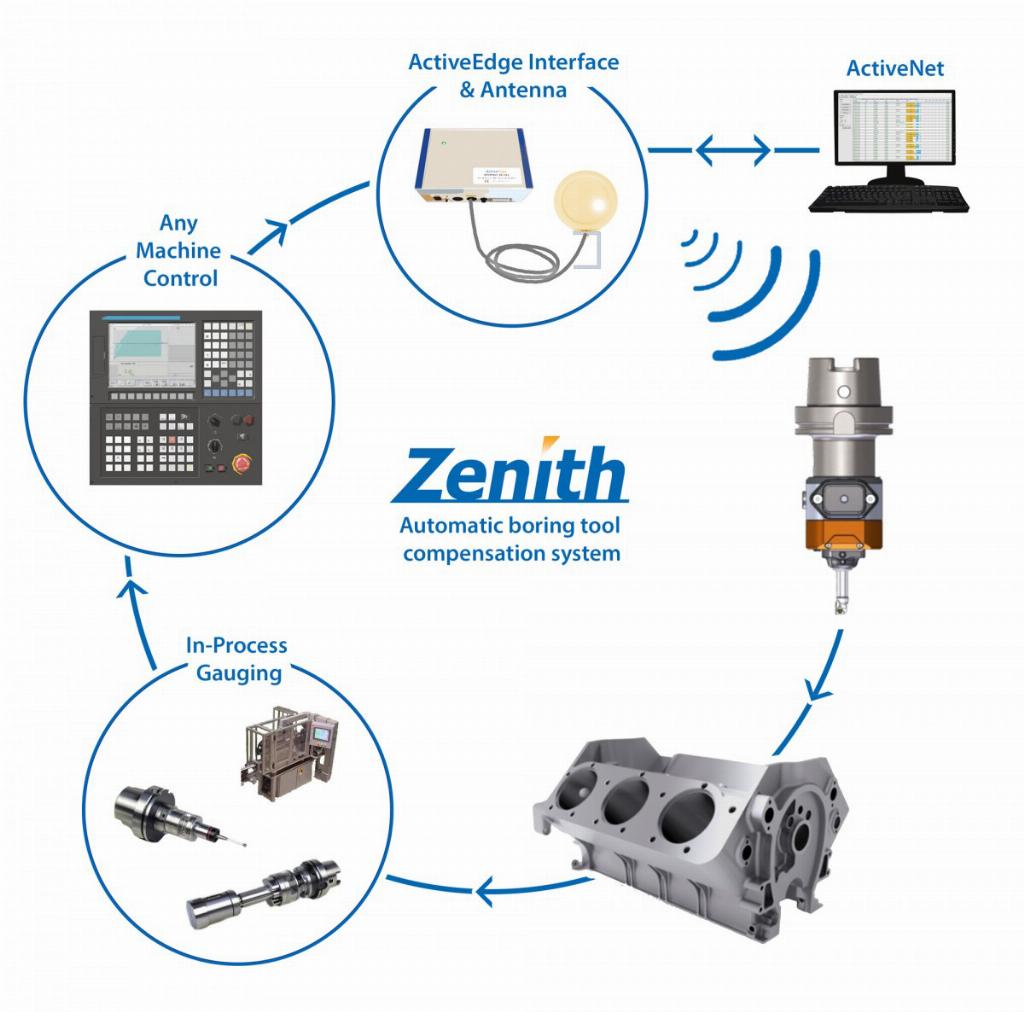

The Apex boring head revolutionises boring operations thanks to its application of a closed-loop compensation system that automatically adjusts the diameter being cut as a result of commands sent directly from the machine tool’s control, based on values calculated by in-process measurements.

The boring head is adjusted with micron accuracy, anywhere within the machine, completely independent of operator intervention. Compensations can be made with the head in the spindle or even whilst it remains idle in the tool carousel while another operation takes place, creating the most efficient machining cycle. Assurance that the correct adjustment value has been made is confirmed via direct feedback from the tool to the ActiveEdge interface.

EMO provides the ideal platform to build on what has already been significant interest in the automated Zenith solution from Rigibore from customers within the aerospace, automotive, wind power and injection moulding sectors, where consistent bores and uninterrupted production are of primary importance.

“Typically, manufacturers experience all too familiar problems with conventional boring heads, mainly the headache of accurately setting and maintaining fine tolerance limits, with high scrap rates impacting on bottom line performance. The requirement for operators to constantly check boring heads for accuracy, and then living in fear of backlash, and slowing production can now be eliminated,” comments Rigibore chairman Roger Bassett.

“Rigibore’s Apex boring head provides manufactures with a perfect bore, first time, every time, using macros to accurately adjust the boring head within predetermined tolerance parameters, all whilst reducing cycle time.”

Rigibore www.rigibore.com EMO: Hall 4, Stand D03