Less of a grind automation

Faster, more accurate, and more cost-efficient machining is just one of the advantages of automating grinding processes. Factors such as health and safety for machine operators also plays a role. This is why Swiss grinding CNC machine tool specialist Studer says it has become a technology leader in automation. Ed Hill reports.

“There are still a lot of prejudices about automation in grinding," says Daniel Schafroth, systems division manager at Studer. “There are frequent concerns that people or jobs could become redundant. However for us at Studer the opposite holds true. Automation should enable human operators to do their work more easily, efficiently, and safely.”

He continues: “For grinding, it is particularly important that processes are performed repeatedly in the same way, with high precision and reliability, for example clamping workpieces and aligning them correctly with micrometre accuracy. Automatic solutions for multi-machine operation are also relevant, as these can greatly relieve the workload of the operators, who no longer need to laboriously load each machine.

“However, grinding fundamentally requires operators with a high level of competence, and automation should not be something that hinders them in their work. Automation only makes sense where the operator doesn't have a decisive influence on the process.”

If correctly used, automation can be a real gamechanger for grinding companies – regardless of whether it is a small business or a large company with several systems.

“Automation pays off for all sizes of companies,” Mr Schafroth asserts. “This may mean that a small workshop with only a few employees can fill the grinding machine in the morning and let it work autonomously for extended periods while the employees take care of other things.”

easyLoad

Studer says its easyLoad system for external and universal cylindrical grinding machines (S31, S33, S22, and S41 models) offers excellent value for money, including integration with the machine control, which is explicitly aimed at small companies.

easyLoad is suitable for use as a gantry loading system for shaft parts with a workpiece length of up to 300mm, a diameter of up to 30mm, and interfering contour diameters of maximum 50mm. The adjustable synchronised conveyor allows autonomous processing of a maximum of 50 workpieces. The standard gripper is designed for individual parts, the V-gripper for two parts, and the heavy-duty gripper for workpieces that weigh more than 5kg. Changeover time is only around six seconds which enables the machine to run autonomously for half an hour or longer with ease.

Larger volume

Studer has also optimised automation solutions for larger-volume series production.

“Small companies mainly benefit from flexible systems, whereas speed and precision are the important factors in the production of large quantities,” Mr Schafroth says. “Here, good automation concepts can produce a large number of high-quality workpieces and make the most of every second.”

The ecoLoad for the Studer S22 production platform is an automatic loading system for large series production using high-speed grinding, production-orientated cylindrical grinding, as well as form and thread grinding.

The system can load workpieces with a diameter of up to 50mm and a length of 250mm. This is either achieved using a carousel magazine or an insertion prism, which can also be used as the interface for standalone tool magazines. The programming is integrated into the grinding machine control to ensure short retooling times.

Studer’s uniLoad automatic loading system also makes it possible for operators of the Studer S31 and S33 external cylindrical grinding machines to significantly increase productivity without any loss of quality.

The system docks into the machine from the left side and with a prismatic conveyor and with all racks at full capacity, it can perform automatic processing for around an hour. It is suitable for workpieces with a length of up to 350mm and 100mm diameter and therefore covers a large range of the parts normally produced on these machines.

Smaller space options

Solutions for applications with limited space are another important trend in the automation of grinding.

“In modern production halls, it is particularly important to make efficient use of space,” Mr Schafroth comments. “With the smartLoad system for the S11 – a production cylindrical grinding machine for small workpieces which has a footprint of only 1.8m² – the accompanying smartLoad unit is also compact. It can feed in workpieces from outside the machine, using either a conveyor or a swivelling unit, as well as clamp them and place them back after machining. Thanks to the wide variety of configuration options, numerous applications are possible, for both small and large volumes.”

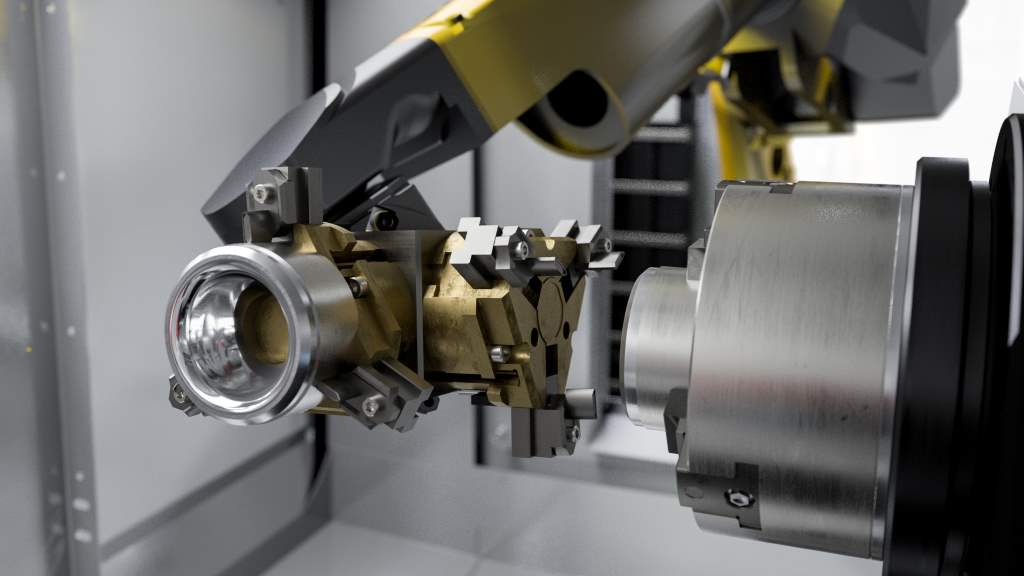

In the past, radius internal cylindrical grinding machines used for manufacturing drawing dies for example, have been particularly difficult to automate due to the limited space available. One reason for this is the restricted enclosure geometry resulting from the high workhead. Studer has now developed an optimal solution for this as well called roboLoad.

This external loader for S121, S131, and S141 machines is designed as a gripper arm with quick change jaws and has a lot of space for workpieces on six trays (each 1,080 x 320mm). At 1.5m, the system is only half the width of the machine itself.

“With the robot arm outside the machine we gain a lot more freedom thanks to the rotation axis,” Mr Schafroth explains. “RoboLoad can load and unload without a direct path available. Until now, automation solutions for grinding were largely based on linear technology such as beams and slides, however, roboLoad is not primarily intended for large series work, but more for automated production during night shifts or extended breaks.”

Digital solutions

Automation in grinding means more than just machine tending. It is equally important to have digital assistance such as that offered by Studer’s grinding software and in particular its C.O.R.E. control, the new cross brand hardware and software architecture of the United Grinding Group’s machines.

On the large C.O.R.E. touch display with intuitive icons, operators can quickly find what they need and important information regarding the machining process is displayed. RFID access chips can be used to let the machine only display the options and information for which the individual users are qualified.

“This prevents unqualified employees from making changes that could cause an error or a crash,” explains Mr Schafroth. “With the application of United Grinding Digital Solutions, efficient remote monitoring of the machines is also possible, and in the future, machines will monitor themselves for optimal functioning and proactively provide information on required maintenance measures.”

The possibilities for automation in grinding are very diverse and offer big advantages on many different levels. However, as Mr Schafroth emphasises, the focus must always remain on people.

“Automation also protects the safety and health of the workers. Robots can not only help with lifting heavy loads and performing repetitive, boring tasks but also handle a wide range of different materials without problems. This makes the workplace safer and more comfortable. The best machine technology and automation in the world is useless if it is not accepted by the people,” he concludes.

So, although prejudices regarding automation still remain, they are decreasing and its application is becoming more and more frequent in grinding.

Studer

www.studer.com