MACH 2024: A highway to industry innovation

Five dedicated Knowledge Hubs will feature at MACH 2024 aimed at promoting the latest manufacturing advances to visitors and guiding them on how to adopt technology that will improve efficiency and boost productivity. Ed Hill attended a press event at the Manufacturing Technology Centre in Coventry to hear more.

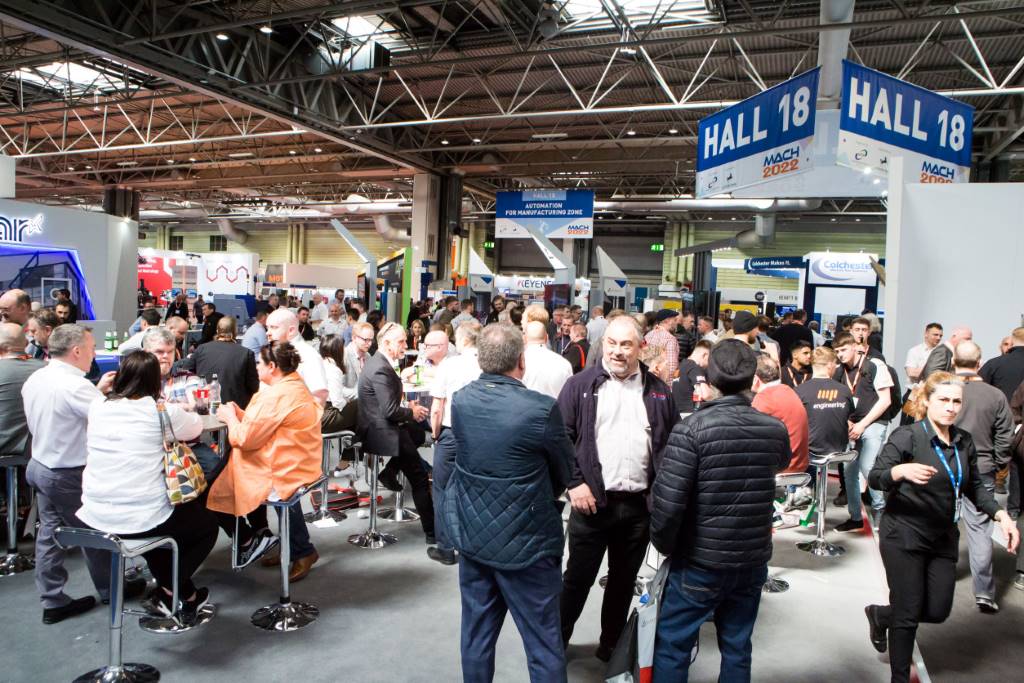

This year’s MACH 2024 press launch focused on initiatives to try and tackle UK manufacturing’s poor record for adopting new technology, so it was appropriate that the event took place at one of the UK’s leading institutions dedicated to the R&D of advanced manufacturing innovations, the Manufacturing Technology Centre (MTC) in Coventry.

In areas such as automation, additive manufacturing and energy efficiency the UK is lagging behind both its European and global competitors.

In fact, when it comes to automation and robotics, according to a report from the International Federation of Robotics, the UK does not even make it into the top 20 when it comes to our use of industrial robots in manufacturing – well behind not only economic giants such as China and the USA, but also the likes of Slovenia, Spain and Finland.

James Fudge, head of operations at the Manufacturing Technologies Association (MTA), which organises the event, began by outlining why MACH is the ideal show to communicate the benefits of adopting the latest manufacturing advances to visitors.

“MACH is the national manufacturing show run by the industry for the industry, he said. “At the MTA we are not just an event organiser; we are the association representing the industry which means we are at its heart and can utilise the knowledge of our steering committee, comprised of leading practitioners in manufacturing, and industry partners to mount the show from that perspective.”

Info in focus

With this in mind, this year’s show will feature a number of ‘Knowledge Hubs’ run in association with the High Value Manufacturing Catapult centres such as the MTC and Advanced Manufacturing Research Centre (AMRC), that will give independent advice on how companies can begin or further their journey towards adopting the latest manufacturing advances.

The five hubs, which will have dedicated stands within the various exhibition zones, will each focus on a particular type of manufacturing technology: Automation and Robotics; Data and Artificial Intelligence; Energy Efficiency; Additive Manufacturing and Tooling.

“We have created the Knowledge Hubs because we wanted to find a way to get information to visitors in an easy and manageable way,” Mr Fudge explains. “This could be companies looking for a specific solution to a problem they have. It could be that they are starting their journey in a new sphere of advanced manufacturing and want to know how to begin. The hubs will provide impartial know-how from people involved in the Catapult Centres, and also direct visitors to appropriate exhibitors in their respective zones so they make the most of their time at the show.”

Mike Wilson, chief automation officer at the MTC, explained why it was participating in running the Automation & Robotics hub this year.

“Automation helps address the challenges that we face in manufacturing including productivity, labour shortages, achieving Net Zero, and most importantly ensuring we have manufacturing capability in the UK to meet our needs,” he said. “According to Make UK there are 70,000 vacancies in manufacturing today that are not going to get filled anytime soon. The only way we are going to address that problem is to adopt more automation. It can also help with reshoring and bringing back manufacturing to the UK.

“Robots can automate repetitive, mundane tasks and allow companies to focus their human labour to where their skills add the most value. However, it’s difficult for SMEs to take the time to investigate their options and know who the best suppliers might be, so they need help to find a solution.”

He continued: “MACH is a key show for manufacturers and 20% of visitors in 2022 said that automation was one of the main reasons they had attended. The Knowledge Hub will help raise the profile of automation and robotics and promote its benefits to the market. Most importantly it will demonstrate that incorporating automation does not have to be a major hurdle. It’s not as difficult or expensive as many people in manufacturing believe.”

Mixing and matching

Exhibits at the automation hub will include a second-hand FANUC Robodrill vertical machining centre attended by a collaborative robot (cobot) loading and unloading system, demonstrating how robots can be retrofitted with existing equipment.

There will also be an ABB autonomous mobile robot, delivering parts to the Robodrill, showing that it is possible to have a mixture of robotic and automation providers. Also, a KUKA additive manufacturing cell will demonstrate the role automation and robotics can have in this relatively new sector of manufacturing.

Mr Wilson added: “We hope these exhibits will engage with the audience and encourage them to ask us how they might be able to invest in automation and implement it in their own manufacturing facilities.”

Tom Bouchier, managing director of FANUC UK, explained why his company was backing the Automation and Robotics hub at MACH.

“All stakeholders involved in automation have a responsibility to grow the market and the only way to do that is by initiatives such as the automation hub at MACH this year, so we can demonstrate all the solutions available.

“The entire range of FANUC products will be on show at MACH – and many of these technologies can be combined. At the hub we will have one of our oldest refurbished CNC machines operating with a new FANUC cobot, being serviced by another company’s conveyer, showing how you can mix new automation equipment with old. Many factory owners have older production technology and think they can’t introduce automation without having to buy a new machine tool, but this exhibit shows that isn’t necessarily the case.

“Automation and robotics is widespread in manufacturing; nearly all consumer products have been touched by a robot, whether they are employed in manufacturing or assembly. We can achieve tangible growth in UK manufacturing by adopting more automation. Things are improving; we expect an 18% rise in robotic installations in UK manufacturing this year, but we still have to do more to keep up with our competitors.”

The automation destination

To conclude the press launch attendees were given a tour of FANUC’s UK headquarters, just over the road from the MTC, featuring the company’s latest CNC systems, robotic and machine tool products, special project areas, and service and support facilities.

The MTA reiterated that MACH is the UK’s only live, national event showcasing sustainable, innovative technologies used across industry making it the destination of choice for companies looking to adopt and invest in the digital manufacturing revolution.

James Selka DL, CEO of the MTA, said: “The MTA is part of a united front of UK manufacturing organisations, along with the MTC, AMRC and MACH 2024 headline sponsor Lloyds Bank, to increase the uptake of technologies such as automation and robotics.

“Only by embracing what the Knowledge Hubs are trying to achieve will the UK restore its position as a sovereign manufacturer and re-establish itself as a major player on the global stage. To have the High Value Manufacturing Catapult centres running our Knowledge Hubs is an indication of the importance these organisations place on our initiative, and with MACH 2024 providing the showcase and the opportunity to see the latest technology live and in action, we couldn’t ask for anything better.

“Greater adoption of the latest technologies will be vital to help improve manufacturing efficiency and optimise productivity. We will do everything we can to help UK manufacturers focus on the new technology, explain when to adopt it and how to implement it to best effect.”

At the time of the press launch more than 85% of exhibition space at MACH had been sold. However, the MTA says companies still considering exhibiting shouldn’t delay so they can secure a location of their choice.

MACH 2024

www.machexhibition.com