MACH 2024: Heller focuses on UK customer support

German-owned Heller Machine Tools, whose factory in Redditch produces selected 4-axis and 5-axis horizontal machining centres (HMCs) for world markets, will stress at MACH 2024 that this facility places it in an excellent position to provide customers with an elevated level of applications and service support.

The Worcestershire facility, which is celebrating its 50th anniversary in 2024, is also a global competence centre within the group for top-level turnkey projects and innovative manufacturing solutions.

360-degree solutions

360-degree solutions is Heller's name for its pre- and post-sales services. Based on this principle, the machine tool manufacturer provides users with solutions to maximise machine availability and productivity, helping them to produce parts reliably and at a competitive cost per part in day-to-day manufacturing.

The holistic Heller service includes time studies which are accurate to ±5%, evaluation of requisite workholding, consideration of automation and unmanned running requirements, built-in chillers for cooling the machine elements if they are required to achieve tolerance, tool life monitoring and broken tool detection.

Machining difficult metals

A particular focus at the show will be Heller's ability to supply turnkey cells for highly efficient machining of tough titanium and nickel superalloys, notably in the aerospace industry but also in other sectors including oil and gas. With this in mind, the machine manufacturer will stress the considerable range of different spindles that it manufactures in-house to suit a vast range of applications.

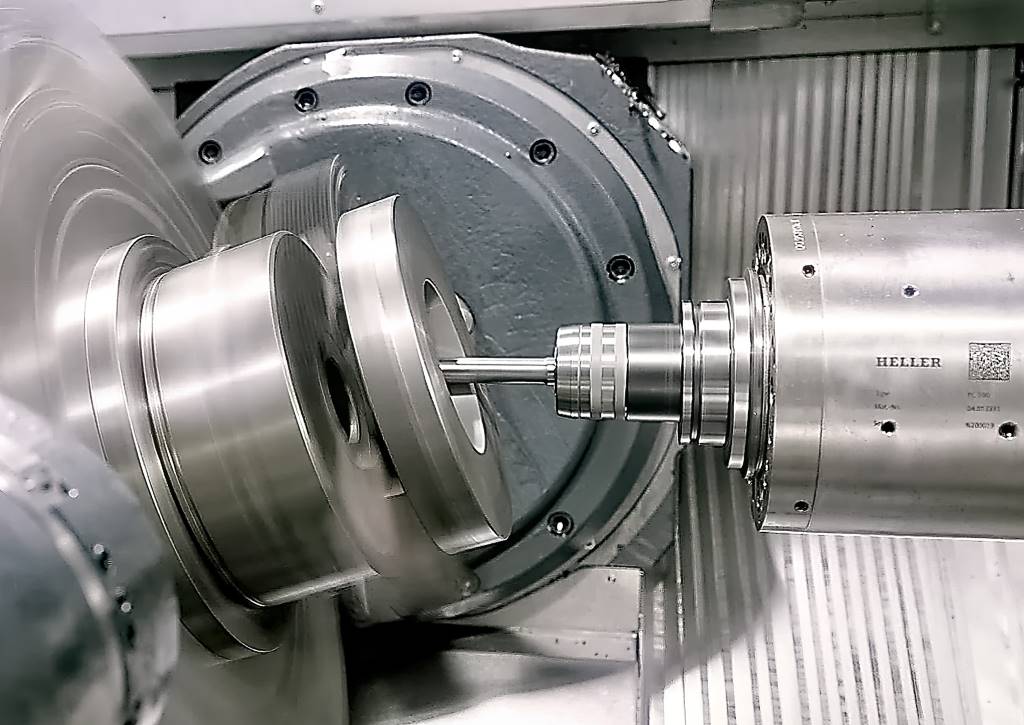

For example, the HMC on the stand will be an HF 3500 second-generation 5-axis model for which it is possible to select a DC (dynamic cutting) universal direct-drive motor spindle, rated at either HSK-A63/16,000rpm/56kW/180Nm or HSK-A100/12,000rpm/45kW/400Nm.

There is also a PC (power cutting) spindle rated at HSK-A100/10,000rpm/45kW/360Nm and an HSK-A100/13,000rpm/45kW/228Nm SC (speed cutting) spindle.

Two further options with an HSK-A63 interface are rated at 12,000rpm/45kW/228Nm (PC) and 18,000rpm/45kW/103Nm (SC). All are produced at Heller's headquarters in Nürtingen and feature the company's Zero-Spindle system for rapid interchangeability.

The 5-axis machine itself, which is built in Redditch, has a 710 x 750 x 710mm working volume. In this case, the machine will be exhibited without a DDT (Direct Drive Turning) rotary table and spindle locking function for turning tools.

New 5-axis capability

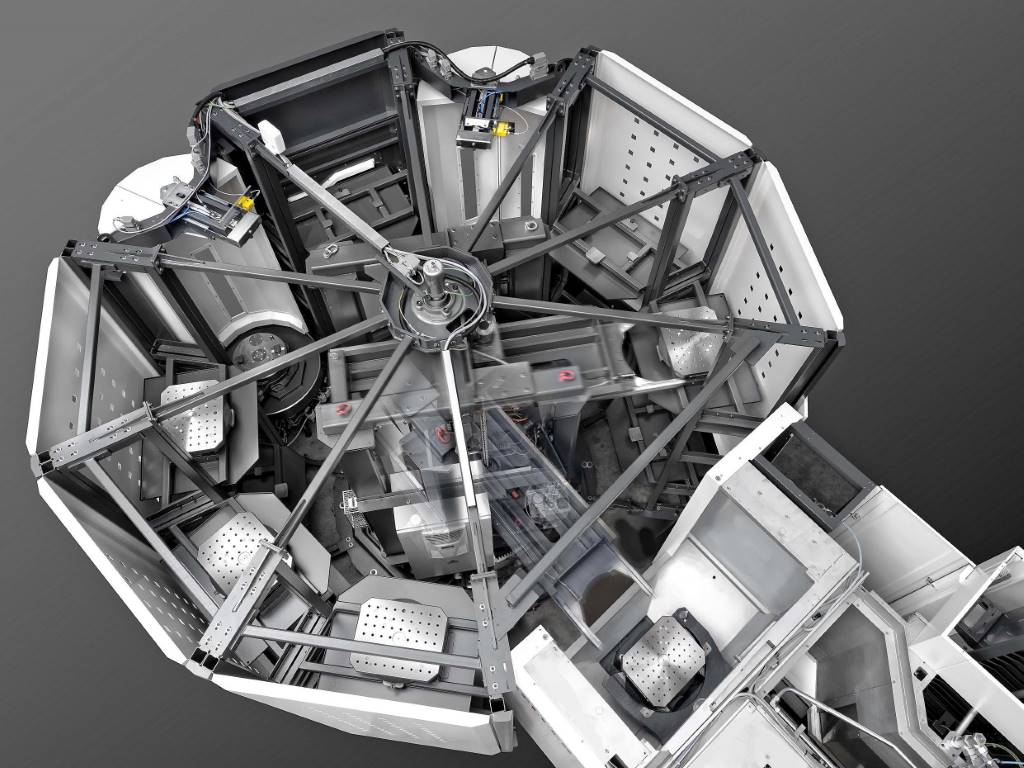

Although not at the show, to be featured prominently on the stand will be the new F 6000 5-axis mill-turn machining centre launched by Heller at the last EMO trade show held in Hannover last year. It has been designed from the ground up following extensive research with the manufacturer's customer base.

Highlights of the new generation include new swivelling heads with integrated motor spindles developed in-house and an optional direct-drive torque table for carrying out in-cycle turning operations. A pallet changer is included as standard for first-level automation, enabling easy integration later on of a rotary or linear pallet storage and retrieval system.

To ensure that all of the above benefits are maximised in production, Heller’s design engineers have focused on clear and easy operation, as well as good accessibility to all work areas. Operation is simplified by the new Siemens Sinumerik One control, which is fitted as standard, and the convenient control unit in panel design with 24-inch touchscreen.

Automation solutions

The main purpose of automated manufacturing on production centres is reduction of idle times to optimise system availability. For this purpose, Heller offers proprietary automation solutions that can be optimally combined with its HMCs.

Due to the wide variety of market requirements, this portfolio is complemented by a range of specialised solutions for pallet exchange, and component handling and storage that the company offers based on best-in-class partnerships, such as with Fastems and Gressel as well as subsidiary companies STS, Paatz and Wenzler. The manufacturer also has a special arrangement with KUKA KMR Cybertech for the integration of automated tool loading and unloading.

Industry 4.0

Featured at MACH 2024 will be Heller4Industry, the group's worldwide drive towards integration of its machine tools and controls into the Industry 4.0 environment. Within the multi-faceted portfolio is the Heller4Services interface, which focuses on transparency of digital manufacturing and maintenance.

The module forms the basis for evaluating machine data and statistics to reduce downtimes. Additionally, visualisation of specific information such as status displays of axes and spindles enables a user to predict wear and implement preventive maintenance.

Other services within Heller4Industry include Energy Monitoring, Axes Condition and Spindle Condition, while the new myHELLER customer portal helps customers keep track of their shopfloor activities, such as ordering spare and wear parts and service visits.

Heller Machine Tools

www.Heller.biz/uk

Hall 19, Stand 330