Mitutoyo engages clutch production

When searching for ways to improve efficiency levels most manufacturers concentrate their efforts mainly on increasing the productivity of manufacturing plant and improving the effectiveness of operational systems.

Although achieving progress in these areas is important, a growing number of businesses are discovering that significant efficiency gains can also be made in the areas of inspection and quality control.

For instance, the impressive speed and accuracy of the latest generation CNC Coordinate Measuring Machines (CMMs) allows users to lower their inspection times and by extension reduce their lead-times.

In addition, by cutting the time that elapses between the manufacture of components and their inspection, parameters that are found to be drifting from nominal conditions can be identified much sooner, adjustments made and company scrap levels slashed.

Finally, the ability of the latest generation CMMs to perform rapid unmanned inspection routines on large batches of complex components releases quality control staff to perform other duties. All these advantages contribute to a company’s bottom line and ensure rapid returns on CMM investment.

Typical of the forward-thinking businesses that has not only improved its production efficiency standards but has also upgraded its quality control efficiencies by embracing the use of cutting-edge CMM technology is Sunbury-on-Thames-based SSS Gears.

SSS Gears manufactures advanced overrunning clutches for high-power/high-speed applications. Conceived for use in automotive transmissions, the requirement for the company’s ‘SSS clutches’ was transformed when gas turbines began to be used for power generation and marine propulsion systems. These two important sectors now account for the vast majority of its business.

The company’s clutches are based on a sophisticated freewheel design and are now used globally on demanding applications where reliability and long life are critical. Owing to industry’s increasing emphasis on energy efficiency and flexibility, the demand for SSS clutches continues to increase.

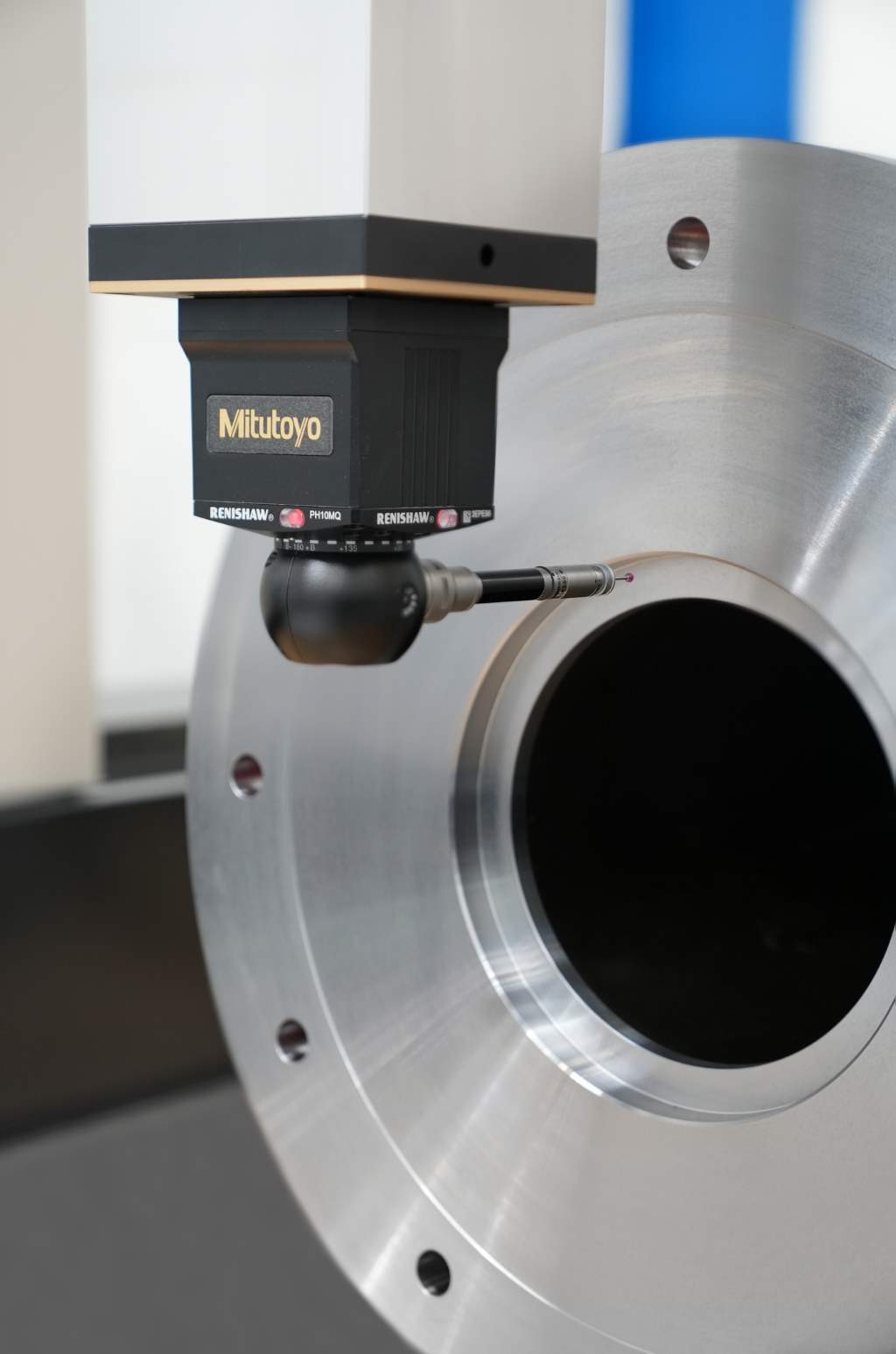

Following the installation of a recently launched Mitutoyo Crysta-Apex-V CMM, the busy company is now enjoying a wide range of quality and efficiency advantages, including improved precision capabilities, reduced scrap and rework levels and significantly reduced inspection times.

Explaining the reasons behind the recent Mitutoyo CMM installation, Vince Masi, engineering manager at SSS Gears says: “Our clutches are used in military naval applications in the USA, UK, Japan and many other countries where individual stringent national quality standards apply.

“Quality is all important to SSS Gears and our quality procedures are equivalent and, in most cases, superior to the requirements of ISO 9001. Our procedures have been developed to help maintain and improve our already proven operating practices and to ensure that all our clutches perform flawlessly throughout their long lives.”

Designed for the connected production environment, Mitutoyo’s new generation Crysta-Apex-V CMMs deliver advances in accuracy, speed and versatility, not only for today’s inspection challenges, but also for the smart factory of the future. The new Mitutoyo CMM range offers advanced capabilities across a range of ten models to cover practically any measurement application in the small to mid-sized part range.

The Crysta-Apex-V series sports a range of advanced features including a real-time thermal compensation system that makes accurate measurement possible even in environments with varying temperatures, such as on the shopfloor.

Now, unlike earlier generation CMMs, a controlled environment is not necessary as the new series machines maintain their high-accuracy specification over the temperature range of 16-26°C. This feature allows automation of inline and line-side measurements within the manufacturing process, significantly reducing measurement times and streamlining workflows.

The CMMs’ active scanning feature enables high-speed measurement by rapidly detecting discrepancies between design values and actual workpiece dimensions, while maintaining the advantages of 3D optimal-path scanning. The intricacies of some workpieces, such as turbine blades and impellers, cause their accuracy to vary or renders them more susceptible to misalignment, causing measurement to be difficult. The V Series enables trouble-free measurement of this type of complex workpiece.

According to Mitutoyo, when compared to conventional CMMs, Crysta-Apex-V models achieve higher maximum drive speeds and acceleration of around plus 20% and 40% respectively. The new CMMs’ faster movement combined with typically 60% higher measuring speed significantly reduces total inspection times.

V Series machines also feature Mitutoyo’s Quick Launch function that enables simple and intuitive operation for easy part-program execution, including prompts via barcodes and QR codes, reducing learning times and making the CMMs’ operation a simple process.

Mitutoyo offers a wide choice of touch-trigger, scanning and non-contact probes to enable Crysta-Apex-V Series CMMs to inspect almost any component surface. An extensive choice of application software is available for automatically generating part programs and to enable the efficient measurement and evaluation of both simple or complex components including gears and aerofoils.

As a response to the advent of smart factories and the arrival of the Internet of Things (IoT), the Crysta-Apex V Series CMMs are equipped with Mitutoyo’s Smart Measuring System (SMS) technology. SMS allows the online monitoring of the CMMs’ operational status and enables the capture of records related to key parts.

Moving forward, Mitutoyo will drive the installation of SMS technology, not only in the company’s CMMs, but also in its other CNC measuring instruments. Leveraging IoT, Mitutoyo will support the realisation of smart factories that controls the flow of information relating to production and quality matters.

Mitutoyo

www.mitutoyo.co.uk

SSS Gears

www.sssclutch.com