Small scale deep hole drilling advances

Conventional deep hole drilling, especially when producing small diameter holes, is usually a slow and unreliable process.

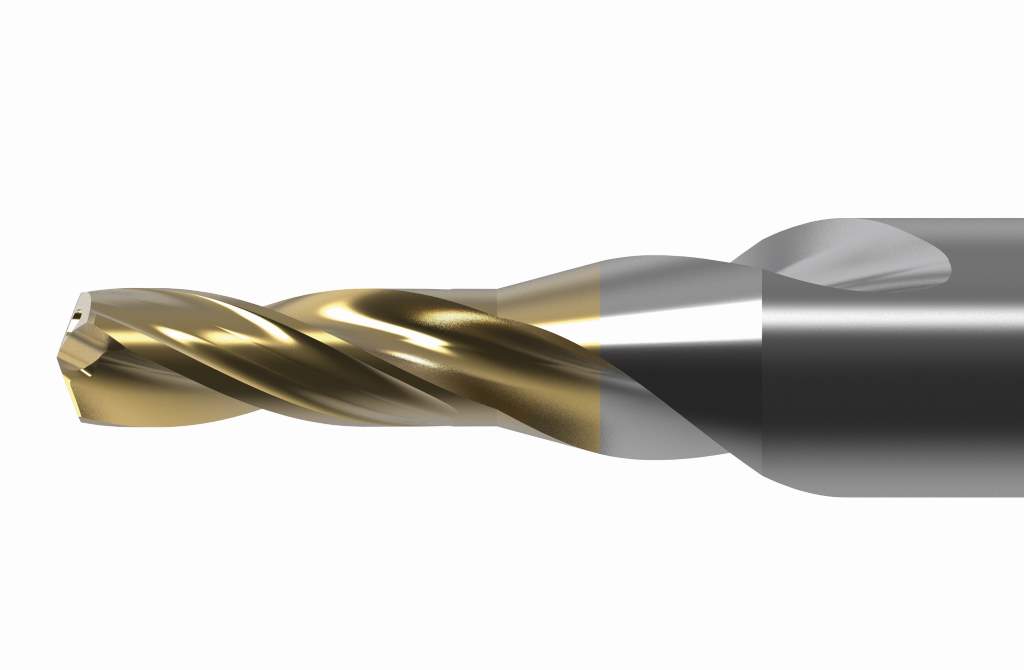

The special purpose DVAS mini drills from Mitsubishi Materials Corporation, and available from MMC Hardmetal UK, have been designed from the outset specifically for drilling small holes in a wide range of materials.

The DVAS series is a total small drilling solution package with a vast range of lengths ranging from L/D = 2 up to 50 L/D and a dedicated set of short pilot drills that start at a diameter of 1mm and are available in 0.1mm diameter increments up to 2.9mm. This means that the pilot drill sizes match the sizes of longer length drills and thus ensures complete compatibility across the whole drilling process.

Starting with the important base material, a brand new micro-grain cemented carbide PVD coated grade called DP1120 has been developed. The new multi-layer coating has an ultra-smooth surface that prevents chip clogging and reduces the instances of breakage commonly found when drilling small diameter deep holes. Additionally, the excellent crater wear resistance helps to maintain cutting edge sharpness that reduces cutting force and also provides long tool life.

The Tri-cooling technology is optimal for small diameter drills and can achieve more than double the conventional coolant discharge volume. This dramatically improves chip discharge and heat dissipation and contributes greatly to tool life and stability.

The straight cutting edge and thinned point are connected by a smooth curved geometry that significantly enhances fracture resistance. The geometry of the rake angle and land also improves tool wear and chip disposal.

The new point thinning breaks chips into the optimum shape for a streamlined flow and achieves a much lower cutting resistance.

The neck is designed for high rigidity and good chip evacuation by tapering the flute instead of having a conventional shoulder. A chip discharge area, provided over the tapered flute section, increases tool rigidity by 20% more than conventional models. Additionally, the extra strength improves hole position accuracy.

Suitable for drilling aluminium alloys, steels, stainless, ductile cast irons as well as titanium, heat resistant and cobalt chrome alloys, the Stub drill series is available from 1 to 2.9mm diameters in 0.1mm increments.

Regular to extra long drills are available from diameters of 1mm to 2.9mm in L/D 7 to L/D 40 with the diameters 1, 1.5, 2 and 2.5mm also having an L/D50 type as standard.

MMC Hardmetal UK

www.mmc-hardmetal.com