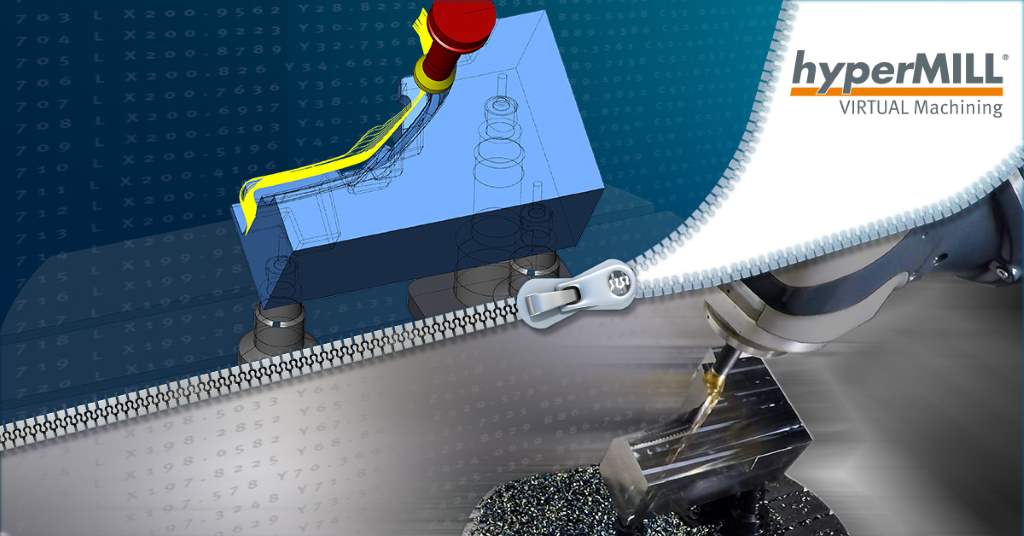

All the process steps for virtual machining

Open Mind is further closing the gap between CAM systems and physical machine environments with its latest version of its hyperMILL Virtual Machining solution.

The integrated all-in-one system eliminates the need for various software solutions as it maps all steps virtually, giving manufacturers absolute control over the machining process. This includes programming, NC code generation and optimisation, simulation of the NC code and networking with the machine.

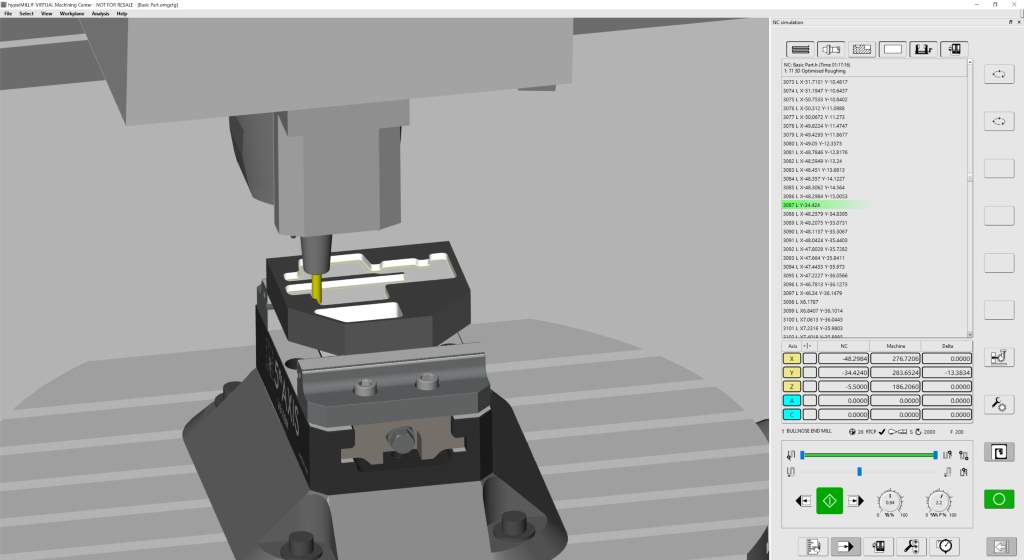

At Open Mind, the development of a safe simulation solution starts long before the NC code. The CAD/CAM developer relies on in-house innovative solutions to build an integrated system where NC code generation and simulation are closely interlinked. The generated NC code is tested extensively, taking into account the limitations of the machine tool. It is guaranteed to run on the respective machines and all process-relevant data is available in the NC code simulation, delivering high levels of accuracy and safety.

Open Mind has equipped hyperMILL Virtual Machining with three modules for merging the virtual and real worlds. In the Center module, real machining situations are virtually mapped for the machine and controller. They are then simulated based on the NC code. The Connected Machining module enables in-depth networking and synchronisation with the machine. For example, the simulation software can detect deviations in the origin or tool positions.

The Optimizer module provides powerful optimisation algorithms that ensure efficient multi-axis machining. It also automatically identifies the best solution for optimal machining results. Moreover, users can write the CAM programs for portal milling machines in the same way as for 5-axis machining centres.

The Optimizer automatically adds the rewinds necessitated by rotary and linear axis limits and by collision control based on the machine’s digital twin. This eliminates unnecessary retract movements to safety positions between two machining steps with the same tool. When combining jobs with the same tool (linking), 2D and 3D machining steps are transformed into smooth movements. The Optimizer can also distinguish between roughing and finishing operations.

Another tool for ensuring greater efficiency and cost-effectiveness in machining is the intelligent component alignment of CAM in real-time using hyperMILL Best Fit. The unaligned part is probed on the machine using 3D probing, and the probing points are sent back to the CAM system as a measurement log. hyperMILL Best Fit then precisely adjusts the NC code to the actual part position. The adapted NC code is subsequently simulated in the virtual machine on the actual clamping setup and optimised automatically.

To ensure safe and accurate machining, the machine operator performs a final verification measurement. After that, the operator can start machining without having to align the part on the machine beforehand. The advantages include immense time savings, collision-free machining, and well-planned processes.

Open Mind

www.openmind-tech.com