Optimised machining begins in the software

Open Mind Technologies AG has now introduced version 2018.2 of its hyperMILL CAD/CAM suite.

In this new release, numerous features – such as drill hole and pocket recognition as well as 3D-optimised roughing have been further improved. The most important additions are to be found in the CAD section: hyperCAD-S. This CAD software, which is specifically designed for CAM programming, provides working solutions to many familiar challenges posed by meshes, faces and volumes, enabling the creation of precise components and tools. The data is prepared for subsequent NC programming independently of the original CAD system.

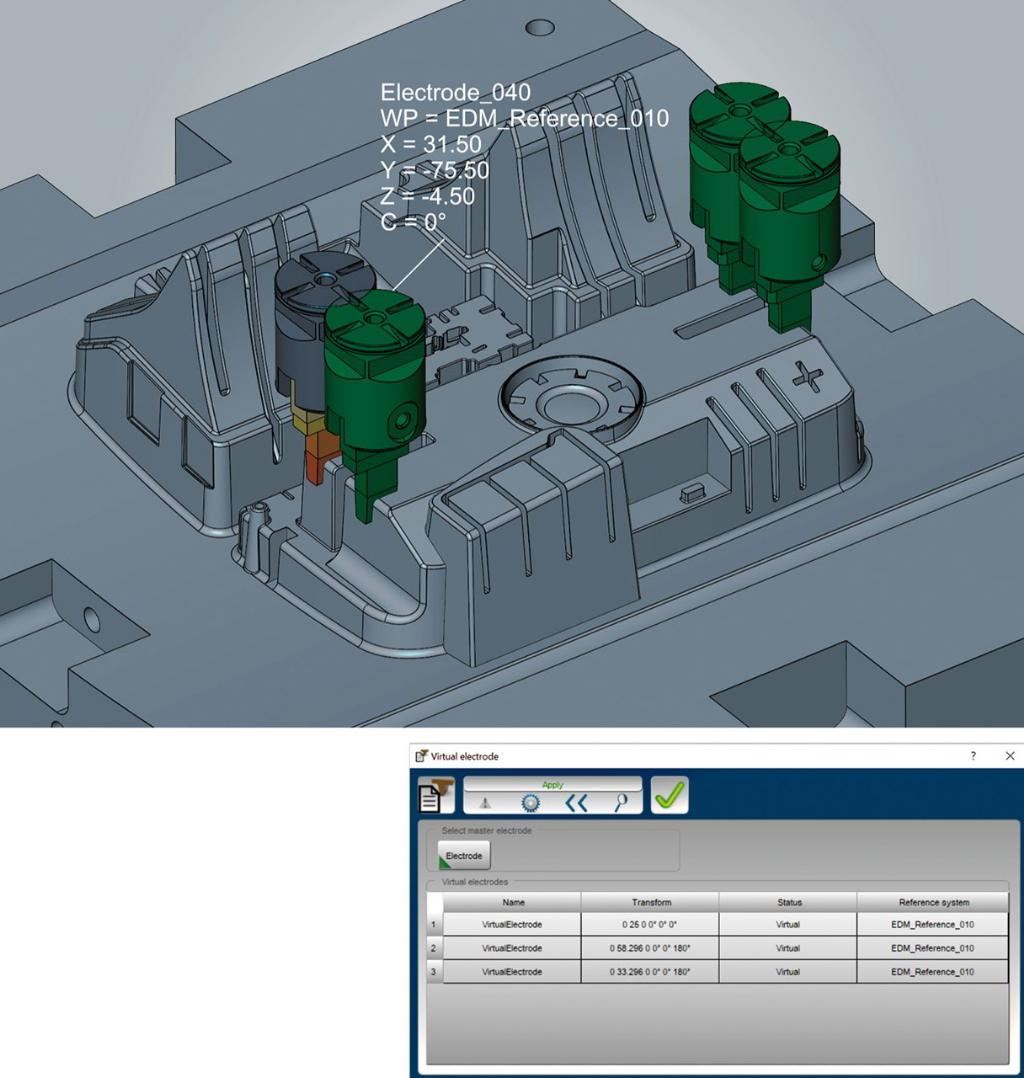

One important new feature introduced in the previous version has been improved even further in hyperMILL 2018.2: the electrode module, which automatically derives electrodes from the faces to be die-sunk within the component geometry. With the ‘Virtual Electrode’ function, copies of an electrode that has already been created can now be generated in various different positions. These are checked for collisions and can be assigned the technology values of the master electrode or new technology values. During electrode milling, these values are processed accordingly. The reference system and eroding position for each copy are included in the report.

Two new functions have now been added to the 3D Z-level Shape Finishing strategy to reduce programming times and improve milling results. The Automatic Face Extension function can be applied during programming to extend the selected milling surfaces. This CAD-for-CAM feature eliminates the need to modify the milling surfaces in the CAD system beforehand. The New Tool Types feature allows barrel cutters to be applied to the 3D Z-level Shape Finishing strategy as a standard tool. Furthermore, this new addition supports tangential and conical barrel tools.

One of the new functions in hyperCAD-S makes it possible to measure the distances between two shapes. This function can be applied to face models, solids, meshes or stock which allows a face created using the ‘Global Fitting’ function to be compared with the original face.

Moreover, casting allowances can be reviewed quickly. The frequently-used ‘Unwrap’ command has now had a ‘Radial’ mode added which allows radially aligned curves or texts on rotational solids to be unwrapped with a constant radial length, which is useful for engraving and tyre labelling.

For easy changes to milling boundaries and turning contours, hyperMILL 2018.2 offers a ‘V sketch’ command, used to assign geometric constraints to 2D contours. When individual contours are changed, the sketch is automatically updated using their dependencies. The values of the V sketches are edited using dimensional constraints and the parameter list.

Open Mind Technologies www.openmind-tech.com