Slide on over

The MACH show may be a distant memory for some but now the rigorous task of chasing up leads and following up enquiries begins.

MACH has always had both short and long-term benefits: some companies are lucky enough to make sales directly from the stand at the show, while others reap the rewards weeks, months and sometimes years afterwards.

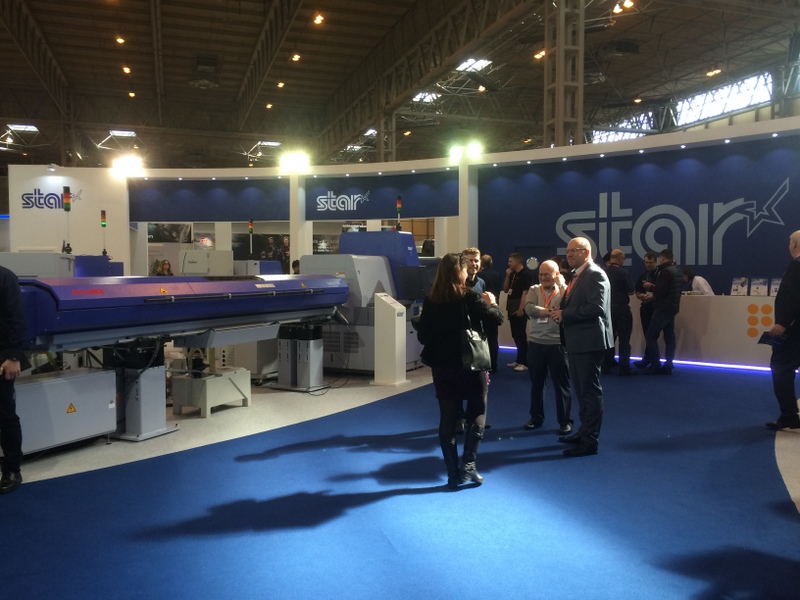

One of the highlights of the event was the presence of Star GB, whose open plan stand showcased the latest and greatest sliding head machines from its extensive range.

Star GB managing director Steve Totty is a stalwart exhibitor at MACH and a firm believer in its power to bring its machinery to new markets: “We do the MACH exhibition every two years because it's a great opportunity for us to promote our brand to a wider audience of potential users within the turned parts industry.

“Star as a company are now building larger diameter sliding head machines in Japan – up to 42mm – so we can now attract companies who previously had to rely on fixed headstock machines into considering sliding head technology – taking advantage of benefits such as improved speed and accuracy.”

Among Star’s array of machines at MACH were a couple of new additions, each representing significant advancements in capability.

The largest diameter Star machine to date, the SR-38, can accommodate bar up to 42mm diameter in non-guide bush mode – putting the machine in direct competition with twin spindle, twin turret fixed head machines. The machine is equipped with a fully programmable B-axis enabling angular features on both front and back working along with 5-axis simultaneous capabilities where required.

Fitted with the Fanuc 31-IB5 control system, the machine can work bar as small as 5mm diameter with high levels of accuracy. It also offers excellent metal removal rates and can machine 40mm bar down to 20mm in a single hit – all with a footprint just 12% bigger than the current Star SR-32J.

Designed with ease of set up in mind, the SR-38 is ideal for both small and large batch production. The flexibility on offer has already proven popular with existing customers – so much so that there were five orders placed last October before any delivery dates were even available.

However the main draw on Star's stand was the unveiling of the brand new SV-20R. The smaller sibling of the SV-38R, this machine is designed to handle intricate, high value parts, making it particularly attractive for demanding industries such as medical and aerospace.

The SV-20R's platen is equipped with five cross-working driven tools, seven turning tools and a flexible eight station turret making it ideal for the high-speed machining of complex components. The ability to perform balanced turning and milling operations, together with the Super Positioning function, empowers the user to reduce the majority of idle time within any program, therefore significantly reducing cycle times. The independent eight station driven rear tool platen further increases the amount of overlapped operations that can be carried out to improve cycle time and productivity.

An unexpected attraction at MACH was Star's demonstration piece. The team produced an all-new giveaway item named the Star Saber – an entirely CNC turned replica based on the iconic Star Wars weapon.

Each component was produced on a different machine to showcase the specialities of each lathe, and individual sabers could even be finished with a custom engraved name. A light feature was also added, which used an acrylic lens to focus light from a bulb at the end of the shaft in the shape of the Star logo.

With the exhibition now wrapped up and all eyes on the future, Steve Totty sees Star in a stronger position than ever before: “We'd like to think over the last ten years we've strengthened our position in the market and now we'd be seen up there as the number one supplier of sliding head lathes here in the UK.

“We're having a new factory built as we speak in the centre of Derby; it'll give us a springboard to move forward, rebrand ourselves and further educate both existing and prospective customers about the real benefits of our sliding head technology.”

Star GB www.stargb.com