Southern Manufacturing & Electronics – be involved in its 25th anniversary year

The annual Southern Manufacturing & Electronics will take place early next month. A firm favourite on the show calendar, PES takes a closer look at what visitors can expect to see at the Farnborough Exhibition Centre from 7-9 February 2023.

As in previous years at Southern Manufacturing, hundreds of firms will highlight a vast array of mechanical, electrical, electronic, electromechanical, hydraulic and pneumatic components and assemblies, PCBs, connectors and sensors, as well as items such as drives, rotary encoders, linear scales, fasteners, pressings, wireforms, springs, plastic and rubber mouldings, gaskets, and much more.

There will be suppliers of machine tools and tooling, workholding systems, metrology equipment for both tactile and non-contact measurement and inspection, finishing machines, laser cutting and marking equipment, additive manufacturing machines and consumables, production and planning aids, and engineering and business software. Industry 4.0 solutions will be in evidence alongside controls, displays, HMIs, data acquisition systems, virtual reality, robot and cobot machine tending and other automation solutions.

Other diverse and no less essential products and services on offer will encompass oil and coolant supply, workshop equipment, dust and fume extraction, humidity control, workplace storage systems, bespoke case and foam manufacture, plastic packaging, injection moulding, hand tools, adhesives, industrial flooring, waste removal and recycling, training, freight services and financial consultancy.

A large proportion of exhibitors have supported the show since the very beginning in 1998. Then it was a small, regional gathering of entrepreneurial engineering firms but it has grown to become the UK's largest annual engineering exhibition and one of international significance, attracting visitors and exhibitors from all over the world.

It moved to its present location in 2008 and was the first event to be held in the Farnborough exhibition centre when it was newly built in 2018. The show that ran two years later, just before the pandemic, hosted nearly 800 companies and welcomed 9,256 people through the door.

Having the best of mechanical engineering and electronics operating at the forefront of technology and innovating across a multitude of sectors under one roof gives the event a real character. Companies looking to strengthen their order books and find new business opportunities in these turbulent times will do well to visit.

At a time when supply chains are under pressure, it is the go-to place to address multiple sourcing requirements efficiently, an endeavour helped by there being no physical barriers between the different engineering disciplines. Visitors often say this is useful, as it can lead to the discovery of suppliers and technologies that would otherwise be missed. Firms with expertise in similar areas are grouped together, allowing Technology Trails to guide visitors logically around the showground.

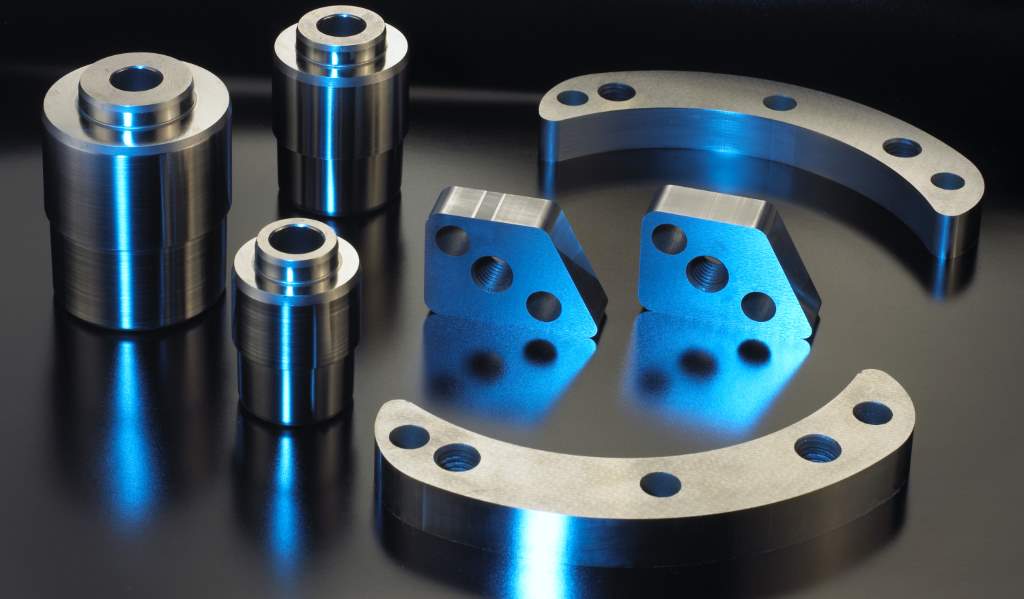

The event is also an important destination for engaging with subcontractors. Leading companies will show samples of components they have machined from a vast array of materials, from exotic alloys through castings to composites and plastics.

Subtractive machining firms will be joined by others specialising in metal and plastic 3D printing. Further subcontract engineering services will include electronics assembly, finishing, test and inspection. All will be keen to explain how they can help industrial companies maintain momentum and profitability throughout 2023, despite the well-publicised financial and supply chain headwinds.

Alongside the exhibition and demonstration areas, over the three days there will be an extensive technical seminar programme, which will be particularly strong this year. It will give visitors and exhibitors alike valuable learning opportunities, with a particular focus on the technical, managerial and environmental issues facing manufacturers today.

Presentations will span such topics as lean continuous improvement, design for test, marketing, team motivation, additive manufacturing, business succession planning, management techniques, CE and UKCA marking, the role of IP in commerce, social media for lead generation and other marketing strategies, commercialisation of ideas, and testing.

Southern Manufacturing & Electronics 2023 opens from 7-9 February and will co-locate again with AutoAero, a specialist theme within the exhibition devoted to aerospace and automotive engineering. There is a regular, free bus service between Farnborough’s railway stations and the show. Parking is also free of charge, as is admission to the show. More information regarding entry and a full list of exhibitors are available from the event website. www.industrysouth.co.uk

Machine tools and peripherals

There will be much to interest readers at the exhibition in many different areas. Here is a taste of some of the products and services on show.

The presence of machine tool companies is particularly prevalent this year, with more than a dozen leading names represented, either the UK and Ireland subsidiaries of global OEMs or their sales and service agents. Ajax Machine Tools (Stand J220) will have examples of Atom CNC lathes with Fagor and Siemens control options on its stand, as well as Proton 3-, 4- and 5-axis machining centres with Siemens controls. The company additionally supplies manual lathes and mills, drilling machines and grinders.

AMOB UK (Stand G210) offers one of the largest ranges of equipment for tube and pipe bending and end forming. Solutions range from simple manual machines to electrically powered CNC systems. A leading manufacturer specialising in mandrel, rotary draw and section bending, the company designs and develops products for bespoke applications in the automotive, marine, offshore, aerospace, chemical, construction and power generation industries.

Bruderer UK (Stand N235) will be back to promote its servo feeds, coil and wire handling equipment, gas springs, tooling, roller and spray lubricants, press and tool protection monitoring systems, quick tool change and workholding devices, spotting and try-out presses, die turnover units, and high tonnage mechanical presses. Chester Machine Tools (Stand D270) will present its own brand of CNC and conventional machine tools as well as its portfolio of third-party equipment including Kitchen & Walker drilling machines, Brierley grinders and Astra lathes, mills and saws.

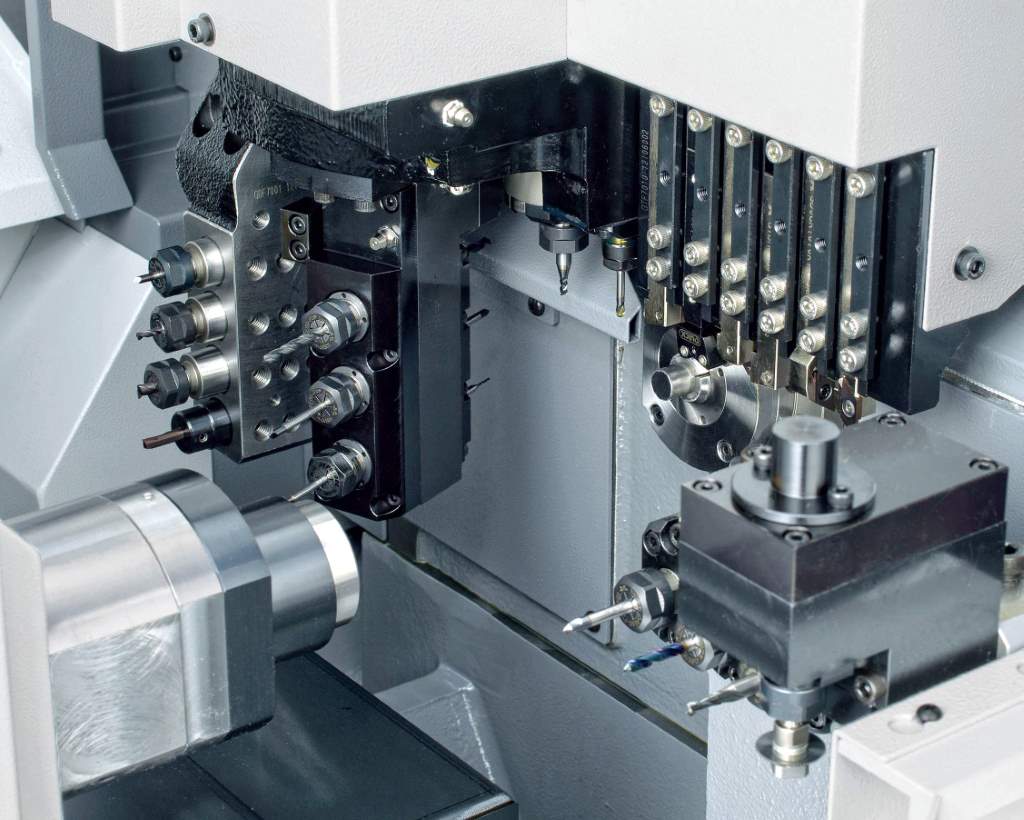

In the area of sliding-head turn-milling, Citizen Machinery (K170) will have a Cincom L12-VIILFV with integral laser cutting capability on its stand. There is almost unlimited scope for machining geometric shapes and precision holes into solid bar previously drilled within the same production cycle, or directly into tubular stock.

Features are produced much more quickly than could be accomplished by milling cutters in driven stations in the lathe's tool carriers, and to higher precision. The company will also remind visitors of the merits of its LFV (low frequency vibration) software for efficient chip-breaking.

Acknowledged as one of the largest CNC machine tool manufacturer in the world, with over 100 models in its range and more than 14,000 unit sales per year, Haas Automation (Stand G220) asserts that its global installed base of more than 250,000 vertical and horizontal machining centres and CNC lathes are used in virtually every OEM and subcontract manufacturing environment.

Vertical machining centres including 5-axis and dual-column machines as well as CNC turning centres are the specialism of Hurco Europe (Stand G200). The products are designed to suit all types of application, from small one-off components and moulds through to large volume production.

Its easy-to-use Winmax control provides conversational programming at the machine as well as full CNC capability. Exhibited at the show will be a VM-series 3-axis machining centre to underline Hurco's claim to offer in all its models a generous working volume in a small footprint.

Chinese firm Jinan Bodor CNC Machine Co (Stand J210) is another company claiming to be the largest in its field, in this case the production of high-power fibre laser cutting machines at its 30,000 m² factory in Jinan. Total floor area amounts to 50,000 ², including administration, research and development. The company has over 2,100 employees including 350 in R&D.

Staff from MACH Machine Tools (Stand J275) and Machine Tool Sales Online (MTSO) (Stand H310), both part of the Vigilance Group, will take two separate stands. The first will showcase its range of new CNC and manual machines. Models being exhibited will be the high-productivity, DynaPath-controlled MDS 845-8T and MDS 900-4T toolroom mills with integrated toolchanger, a large capacity MDL 1800 flatbed lathe with an integrated automatic tool post, a VS-1SP high precision, turret-type mill and a recently-introduced 1440 UV training lathe. At the same time, MTSO will promote the company's extensive stock of high quality, pre-owned machines.

Live 5-axis machining demonstrations on a 10-pallet, 90-tool MX-330 PC10 machining centre will be a highlight on the Matsuura Machinery (E260) stand, alongside 3D printing on the Desktop Metal Studio System 2 and the Desktop Metal Fibre composites 3D printer, both of which will be running exclusive demonstrations for the show.

The company's strategy is to convince manufacturers that it can supply the best platforms for both subtractive machining and additive manufacturing.

Mills CNC (Stand C160), the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, will feature an SVM 4100 machining centre manufactured by the former, Korean principal.

The machine's BT40 18.5kW/12,000rpm/95.5Nm spindle, impressive rapids and fast acceleration and deceleration are said to dramatically improve customers’ part processing times. Furthermore, a versatile M1509 Doosan cobot will demonstrate the significant productivity and efficiency gains that can be achieved with relatively low-cost automation.

Formed in 1964, NCMT (Stand G230) is one of the longest established names in CNC machining. It is sole UK and Ireland agent for two major Japanese machine tool brands – machining centre, turning machine and grinder manufacturer Okuma, and machining centre and EDM machine producer Makino. At the show, it will be exhibiting an Okuma M460V-5AX 5-axis, compact, vertical machining centre designed to manufacture high precision parts while delivering impressive metal removal rates.

XYZ Machine Tools’ (Stands G260/H260) portfolio includes CNC vertical machining centres, turning centres and the popular ProtoTRAK-controlled mills and lathes which are ideal for one-off to medium volume production.

The highlight at this year’s show will be the company's new TMC range of four toolroom machining centres, which combine the advantages of the latest ProtoTRAK control with a fully enclosed machine design and up to 20-station toolchanger. Each model is equipped as standard with electronic handwheels in all axes, so users can work the machine as if it were a bed mill, using the DRO facility for manual machining. One of two stands booked by the company will be dedicated to demonstrating this product line.

One of the world’s largest manufacturers of machine tools and laser cutting machines, Yamazaki Mazak UK (Stand F180) will return to the show with a stand centred on accessible, 5-axis, automated machining for subcontractors, start-ups and job shops.

In pride of place will be its UK-made CV5-500 vertical machining centre equipped with a compact, plug-and-play MA-20/400 automated component loading and unloading system to enable lights-out operation. The workholding structure is of rigid construction comprising a 500 mm diameter rotary table on a trunnion travelling in the Y-axis to deliver a high accuracy, compact machining solution.

With rapid traverse rates of 36m/minute in the linear axes, the machine delivers agile performance that can be boosted by an 18,000rpm, 18.5kW spindle.

Another firm specialising in the supply and support of advanced machining centres, CNC turning centres and integrated automation is YMT Technologies (Stands E210, E215, E220).

It also has a division providing workholding and tooling at competitive prices. The company will be exhibiting new, high precision toolholders from Tuscan and a range of machine vices and tables, as well as Jergens fixturing and workholding.  There will also be Tuscan rotary tables on the stand and a mist extraction system from AR Filtrazioni. In addition, Diebold heat shrink machines will also be promoted.

Many accessories in and around the machine tool will be present on numerous stands. Oemeta (Stand E190) and Kernow Oils (Stand K225) will promote their coolants, cutting oil, lubricants and greases. The former says it is keen to explain the advantages of its HYCUT multifunctional metalworking fluid concept based on a coolant, neat oil and washing fluid, each of which is compatible with the other, allowing a user to control independently the amounts of oil and additive in an emulsion.

Cutting tools and toolholders will be represented by Industrial Tooling Corporation (Stand H250), Guhring (Stand H185), Hoffmann (Stand F190) and Mapal (Stand E180), while Zoller UK (Stand J200) will demonstrate its tool presetting and measurement equipment.

Heidenhain (Stand A230) will show its CNC systems, DROs, encoders, touch probes, camera systems, length gauges, signal converters and inspection devices. The use of modern, modular workholding equipment and automation instead of machine vices and manual loading will be advocated by 1st Machine Tool Accessories (Stand G205), Lang Technik UK (Stand L250) and Thame Workholding (Stand J230). Roehm (Stand K260) will make clear the advantages of using its new Duro-M series of two-, three-, four- or six-jaw lathe chucks for clamping parts on turning and milling machines, rotary tables and dividing attachments.

Thame Workholding (Stand J230), a renowned UK manufacturer and solution provider will be demonstrating new products at Southern Manufacturing & Electronics 2023.

Making its first showing in the UK will be AirVise’s precision self-centring pneumatic vice. Available in a 4-inch or 6-inch table version as well as a 4-inch variant for rotary applications these vices provide adjustable clamping force (11kN at 110psi), quick change soft jaws and a compact footprint.

The vices can be used both manually or as part of an integrated system using collaborative robot loading and unloading for maximum productivity (UR+ ecosystem certified).

Also, on show will be the new 52 pneumatic zero-point plate manufactured by HWR which compliments its extensive range of mechanical zero-point technology. This plate will allow automatic loading and unloading when integrated into the machine operation.

3D printing

Additive manufacturing solutions will be almost as strong as subtractive machining, considering that many firms in the latter category are offering the former functionality as well.

In addition to the Matsuura offerings already noted above, many companies supplying additive manufacturing equipment only and bureau services will be exhibiting. Additive-X (Stand E185) is a 3D printing specialist selling and repairing 3D printers, as well as providing professional advice and a print service. Displayed on its stand will be a range of machines and additively manufactured parts and its engineers will be able to answer any questions visitors may have.

Carfulan Group company SYS Systems (Stand J200), which distributes Stratasys 3D printing technology and specialises in both PolyJet and FDM-based printing technology, is another additive manufacturing equipment provider taking part. So also is CDG 3D TECH (Stands P230, P225), which partners with 3D Systems, Intamsys, Sinterit, Omni3D, Fusion, Zmorph and Inkbit, while also offering 3D scanners as well as Evatronix, Shining3D and Geomagic software.

Creat3D (Stand J270) similarly supplies 3D printers together with consumables, support and services including training, maintenance, managed services and applications engineering. Additive technologies include FFF, SLA, SLS, composite, metals and high temperature, large build format 3D printers.

The company will allow visitors to get hands-on with the latest materials including nylons, high performance ULTEM, composites and fibre reinforcements, metals and flexible materials. Samples displayed will range from components for drones and electric vehicles to industrial equipment and end-of-arm tooling.

Europac3D's (Stand J145) scanning and printing equipment will be on show and its bureau service will be promoted. Its Artec3D handheld scanners offer fast, portable digital capture of almost any 3D shape, ideal for reverse engineering and quality inspection.

Uniontech SLA resin additive manufacturing systems are focused on large build volume applications and are compatible with a comprehensive range of open source materials. Kreon portable measuring arms in both 6- and 7-axis versions will also be on the stand. New for 2023 is Supar Augmented Reality Interactive Inspection software that utilises the scanning technology embedded inside the iPad Pro.

Lastly, the latest MakerBot METHOD X 3D printers will be shown by GTX Europe (Stand K100). Designers are able to use the machines to print parts with accuracy and speed from their desktop in a range of plastics, carbon fibre and other materials. The company offers 3D imaging devices and scanners as well.

Metrology

Many established names in the area of inspection, measurement and quality control will be encouraging attendees to check out what they are presenting.

Arc Metrology (Stand M235) offers support, equipment and software solutions encompassing metrology workstations, enclosures, custom fixtures, fixture kits, baseplates and CMM artefacts. The firm is able to provide subcontract inspection; training in CMM programming, operation and GD&T (geometric dimensioning and tolerancing); fixture design; reverse engineering; 3D scanning and inspection; and cover for absent CMM operators and programmers.

Ash Technologies (Stand A205) is an Irish company specialising in digital magnification and imaging solutions for production process improvement and fault detection. Its cost-effective inspection and measuring devices are able to raise operator productivity and assist in training.

Blum-Novotest (Stand L210), a developer of in-process component and tool measurement solutions for the machine tool industry, will demonstrate its products for supporting automated CNC machining to ensure that every part is good and that work and scrap are avoided. On display will be the latest Digilog family of products. Working demonstrations will seek to persuade visitors that data feedback for shop floor quality control is essential for boosting a manufacturer's bottom line.

Moore & Wright, Baty, Sylvac, Trimos, Wyler and Gagemaker are all brands of the Bowers Group (Stand L240), which will be exhibiting a variety of metrology instruments. In addition to a range of standard and bespoke products designed and developed by its application team in Bradford, a selection of third-party calibration tools, height gauges, hand tools, vision systems and optical profile projectors will also be on show.

Carfulan Group is active in metrology as well, with member companies OGP UK and Vicivision UK (Stand J200) present at the show. Another firm, Optimax Imaging Inspection & Measurement (Stand D190), markets products from Alicona, Starrett, Inspekto, Mahr and Vision Engineering. On its stand will be the Alicona InfiniteFocus universal optical 3D measuring instrument, while other products will include the latest AI-guided visual inspection tools, 4K video microscope and video endoscopes. The company specialises in difficult-to-inspect, high precision engineering applications.

Claiming to be a global leader in the manufacture of factory automation solutions, renowned for its wide variety of high-performance products including sensors, machine vision, microscopes, metrology systems and laser markers, Keyence UK (Stand A200) will be showing its latest measurement and inspection line-up.

They include the VHX-7000N, a 4K digital microscope with very high resolution that delivers images rivalling those of a scanning electron microscope. It has an intuitive interface and advanced features such as optical shadow effect mode, one push calibration, automatic report generation and handheld observation mode. Metrology engineers will also see the latest iterations of the IM and LM measuring and inspection systems, which have the repeatability and speed for verifying up to 300 part features in a matter of seconds.

Sempre Group (Stand E270) is another company offering optimum, connected quality control systems and software designed to drive productivity. Visitors will be able to witness an entire quality process completed efficiently with little operator intervention or opportunity for error, from auto ballooning a drawing, through generating inspection plans, loading parts and automating measurement, to importing results directly into FAI (first article inspection) and PPAP (production part approval process) reporting templates.

On the stand will be a Micro-Vu optical CMM, Opticline shaft measurement and Sensofar optical profilers, as well as High QA Inspection Manager software, capable of importing results from any CMM and automating the process of scanning entire drawings and extracting GD&T data.

PC-DMIS powered CMMs and CHOTEST flash measuring machines will be on the stand of Status Metrology (Stand F245), which is also involved in retrofit, service, support, programming and training.

Ergonomic microscopy, digital 3D visualisation and metrology are provided by Vision Engineering (Stand J260). Its stereo microscopes and measurement systems are widely used across the medical, aerospace, electronics, automotive, telecommunications and biomedical sectors. Its Discover DRV-Z1 Deep Reality Viewer is believed to be the only digital stereo inspection system that creates full 3D HD images that can be viewed without 3D glasses.

Software

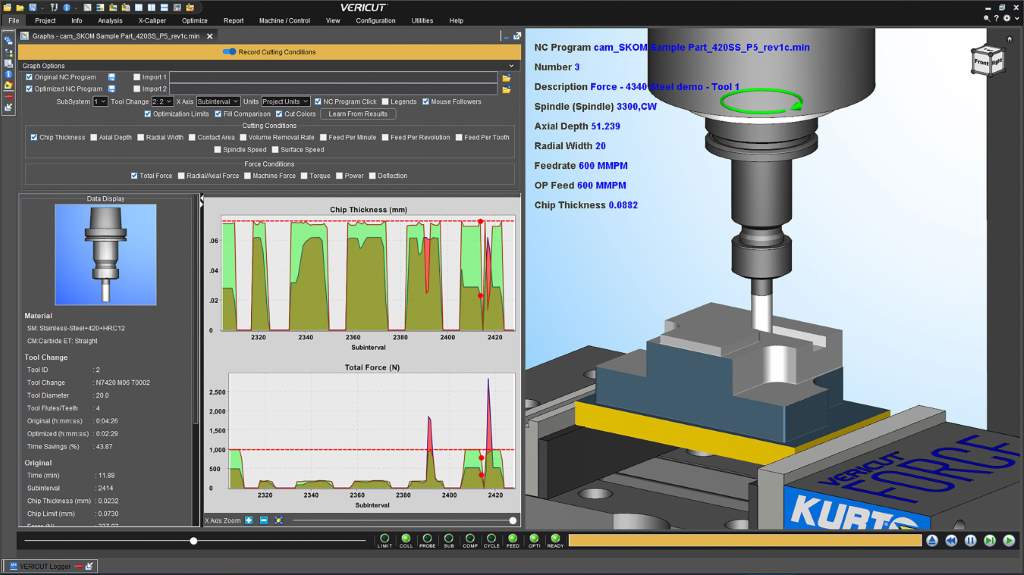

A global leader in NC code simulation, CGTech (Stand C215) offers software solutions that ensure CNC machine tools run collision-free and manufacturing processes operate more efficiently and with increased profit levels, as the company will explain at the show by demonstrating its Vericut CNC simulation, verification and optimisation software.

The software operates independently, but also integrates with leading CAM systems. The company will highlight its Force optimisation module, which in combination with Vericut provides an integrated simulation/optimisation solution that can significantly reduce machining times when running new or legacy programs, extending the lifetime of cutting tools and of the machine tool.

The reduction in program run time typically achieves savings of 8 to 15% when machining aluminium and more when dealing with difficult-to-cut materials.

Another software company, E-Max Systems (Stand G145), is active in the area of enterprise resource planning. Its E-Max ERP is a solution designed to help anyone struggling with spreadsheets or legacy systems, finding it difficult to manage MRP, having to deal with large, multi-level bills of materials (BOMs), or lacking clarity around capacity on the shopfloor.

It covers all manufacturing processes in any production environment. The software has the functionality needed to make informed decisions for optimising production planning, scheduling and works order management, while tracking resources and raw materials.

Described as a true quote-to-cash system, it includes integrated financial accounting for controlling costs. The company is keen to return to Southern Manufacturing & Electronics to promote its new cloud product, as the show's visitor profile very closely matches its customer base of SMEs, precision engineers, job shops, fabricators and subcontractors.

Medatech UK (Stand G120) supplies creative ERP and other IT-related solutions with a wide scope of functionality. Smaller additional modules can be provided for customers in specific vertical markets. Its Priority Manufacturing ERP gives businesses a holistic view of their production facility on a desktop computer, tablet or smartphone so they can optimise manufacturing performance, run leaner operations, boost analysis capability, strengthen customer loyalty and increase their bottom line.

The software focuses on the automation, personalisation and customisation of the system for each user, from hiding unused fields automatically to suggested fields for each user as they log in, as live demonstrations on the stand will attest.

Another provider of ERP and production control software with over 25 years' experience is MIE Solutions UK (Stand B230). MIE Track Pro has been developed to streamline workflow and business practices in manufacturing industries and promote competitiveness at an affordable price. Used by hundreds of UK companies and many more worldwide, it is a comprehensive, non-modular software package that is easy to install and use.

SapmanV12 (Stand E105) is manufacturing and distribution control software that encompasses inventory management, barcoding and labelling, batch and serial number traceability, BOM, shopfloor data capture, MRP and full audit trail. Integrated with Sage 50 or Sage 200, the software takes care of all business processes, from the first sales enquiry through to customer delivery and invoicing.

Visitors to the Theorem Solutions (Stand E250) will experience augmented, virtual and mixed reality and be able to see how full-scale, in-context, collaborative visualisation is changing design.

The company will showcase Theorem-XR, a software suite that delivers extended reality experiences for manufacturing and design related tasks, including immersive visualisation, factory layout, design review, visual digital twins and training guides.

Today, products are rarely developed from a single location and XR is proficient at facilitating creativity via remote collaboration. For many, entering 3D data into XR is the most difficult part of adoption. Visualisation Pipeline automates the CAD data preparation process, as it brings 3D data assets directly into Theorem-XR or allows the creation of assets for internally developed XR solutions. There will also be an opportunity to learn about CADverter direct CAD translation tools, and 3D PDF suite, which enables collaboration and data sharing through interactive documentation.

Finally, Canadian firm VKS (Stand G140) will espouse its intuitive work instruction software that allows quick and efficient step-by-step creation of digital work instructions to standardise and optimise processes, from entry-level to full smart factory applications.

Without the need for paper, users can digitise work instructions, checklists, maintenance processes, audits and much more by recording process and quality data in real-time and integrating it into existing systems. Characterised by maximum flexibility and applicability in production, benefits include increased productivity and quality. It also reduces training times, delivers complete traceability and increases flexibility.

Automation

A couple of independent exhibitors at the show will explain what they are able to offer in the area of automation. Denny Bros Engineering (Stand G255) has over 40 years' experience in manufacturing automation machinery in its Bury St Edmunds production facility for a range of different industries including the label, packaging and pharmaceuticals sectors.

Indus Engineering (Stand C260), a new entrant to the show, specialises in the design, manufacture and installation of bespoke, turnkey factory automation and control systems, offering integration of electrical and mechanical components from all leading brands.

Having worked on major control and automation projects for a number of major customers in the South, the company has recently acquired new premises with the aim of increasing production capacity. The expansion will also allow the firm to support a wider range of engineering activities carried out by the company, such as design, manufacture and test of special purpose machinery.

The virtues of automating machine tools to maximise efficiency and minimise costs in high-wage countries are well documented, but the area has gathered tremendous pace over the past few years, with a plethora of automated pallet, component and tool change options of all sizes being offered.

They range from AGVs moving around a factory floor, through 6-axis industrial robots for machine tool tending and highly sophisticated gantry systems, to cobots working alongside operators on the shopfloor. The many machine tool companies at the show, while not necessarily exhibiting this type of equipment, will be delighted to discuss the possibilities with interested parties.

More products, more technology

Exhibiting on Stand C310 at Southern Manufacturing, thermal processing and ultra-hard coating expert, Wallwork Group, is keen to highlight the significant investments made throughout its UK sites.

Operating from four locations, Manchester, Birmingham, Cambridge and Newcastle, the company provides a rapid turnaround service to customers in aerospace, automotive, motorsport, medical, oil and gas and more.

Since last exhibiting, Wallwork has invested significantly in new capacity for vacuum carburising, plasma nitriding, vacuum brazing, PVD and PVECD coating. “Despite the economy only recently emerging from the pandemic and notwithstanding the current energy and economic setbacks, we are investing to keep up with demand for advanced and specialised processes alongside our more usual heat treatments,” explains director, Simeon Collins.

Besides upping capacity to meet demand, the company has also been upgrading buildings, expanding its own in-house mechanical testing facilities and renewing Nadcap certifications across multiple sites. Maintaining its dedicated pick-up and delivery fleet of vehicles ensures customers can easily, and at less cost than a commercial carrier, get components processed and returned quickly.

“Continuing growth is only part of the story,” Mr Collins concludes. “A strong service ethic is rooted in our people and combining this with low-cost pick-up and delivery, UKAS certified in-house mechanical testing, and Nadcap and multiple aerospace prime accreditations, customers really appreciate the full end-to-end experience with many services accessible from one supplier. Fast, efficient and without compromising quality.”

Developer of visual planning systems T Cards Direct (Stand P150) is celebrating its 60th birthday in 2023 and to celebrate the anniversary, the company will be showcasing the latest release of its T Cards Online system at Southern Manufacturing. The release will include some new innovative features that T Cards has been working on for the last year.

Simple to customise to specific applications, T Cards Online can help improve the efficiency of a business. Benefits are seen immediately as users can start using the software as soon as they register under the no obligation 21-day trial. This includes T Cards Direct’s UK team providing personal support to get you up and running with the minimum of disruption.

“T Cards Online is designed to be used very much like the tried and tested manual system,” explains company partner, Philip Heine. “Clients often need a clear and precise status of work, and this does exactly that but with all the benefits and analysis tools available digitally. Having a ‘Go to Board’ at your fingertips can really help staff get on with their day-to-day tasks in a systematic a structured manner.”

Over the past 10 years the development of T Cards Online has been driven by customers. Suggestions and improvements have been woven into the basic premise of keeping it simple. Being at the Southern Manufacturing show has given the company a platform to discuss these improvements with clients and potential customers alike.

“We have been a regular exhibitor at Southern Manufacturing for the last 15 years, starting with the manual systems,” Mr Heine adds. “Now the Online System is what the industry is most interested in.”

The new release being showcased is a significant step change for the planning and control of work. It includes a new ‘What If’ engine that can generate automated workflows.

“Think of it as an ‘If This Then That’ process – action then consequence,” Mr Heine says. “For example, if a card or job is moved to a predefined position, a consequence or alert is automatically triggered. That consequence could be a clear visual change in colour, an email alert or just a flashing card on the screen. The customer can decide.

“One application already being used is to highlight delays when a due date is passed. Showing automatically on the screen rather than waiting for a report or trawling through pages of data.”

Southern Manufacturing & Electronics

www.industrysouth.co.uk