Springing into accurate action

When Redditch-based Clifford Springs required a precise way of measuring its products it turned to Nikon Metrology for a video inspection solution. PES reports.

How do you determine the diameter of a seal energising spring after manufacture, while it is still an irregular loop of coil with its ends welded together and not yet formed into a circle by the seal it will eventually strengthen?

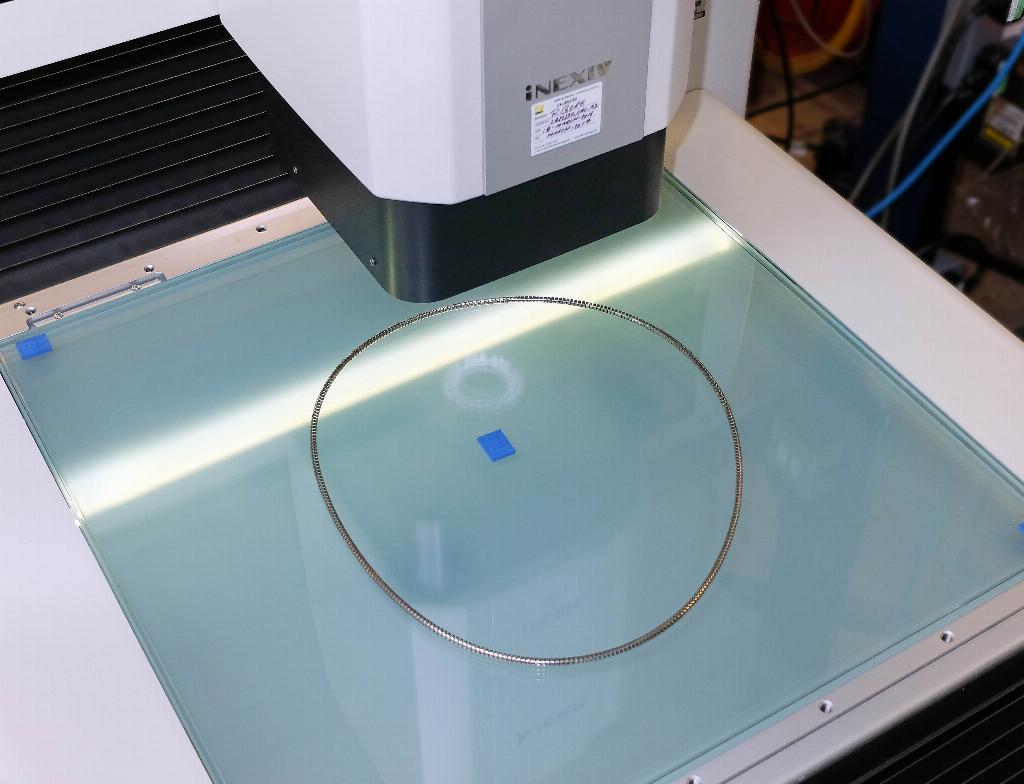

The standard options are traditional circular go/no-go gauges for a specific size of large spring or a conical step gauge rising in 1mm increments for a family of smaller sizes. However, Redditch-based Clifford Springs has established a more accurate process using a Nikon Metrology iNexiv VMA-4540 CNC video measuring machine, installed in May 2016.

To a repeatability measured in single figure microns, the optical measuring equipment automatically determines the length of a freeform loop of coiled spring to determine what its circumference will be when it is circular, after which dividing by pi produces a precise result for the diameter.

Clifford Springs now plans to use the iNexiv VMA-4540 to automatically count the number of coils per unit length of spring, looped or unwelded, which predicts its load deflection characteristics in use. Compared with the present method of manually counting the number of coils in a given length and using a formula to extrapolate the total number for the whole spring, the optical method will be more precise.

Furthermore, measuring the angle between successive coils in a spring and their distance apart is more accurate, as well as much faster, than older manual procedures using an optical profile projector. Another important benefit is that an automated system eliminates the risk of human error.

Managing director John Clifford comments: “Customers are increasingly asking for reports with proof of the numerical values from our inspection of the springs we manufacture, but only the transcription of manually measured results was previously possible.

“Since May this year, the Nikon optical measuring machine has allowed us to print off actual readouts of spring diameter and soon coil count and geometry will be included. It has enhanced the perception of our metrology expertise amongst our customers and increased the confidence they have in our products and reports.”

Springs and springs

Established in 1946, Clifford Springs is one of only a handful of companies in the world that produces such a wide range of canted, helical, garter and meander springs for energising seals. Springs range in diameter from a few millimetres to around 300mm and are mainly of stainless steel, although carbon steel, phosphor bronze and PEEK are also used in the manufacture of some varieties.

Half of production output from the Redditch factory is supplied as coil for the customer to process, the remainder being cut and welded into individual springs. The addition of a spring to a seal provides extra resistance to outward radial forces imparted by a fluid or gas being conveyed under pressure.

With 60% of turnover coming from selling springs into the global oil and gas sector, which is currently suffering a downturn, one would suppose that the company is currently going through a difficult period. This is not the case, however, as market share has been won due to the adoption of innovative production processes, from coil winding to welding and now to product inspection. Other industries in which energising seals are widely used include the aerospace and automotive sectors.

Paul Thomas, development engineer at Clifford Springs explains: “We considered several alternative systems for automating the inspection of our springs. They included blue and white light scanners, but they are better for comparative rather than absolute measurements, and traditional optical profile projectors, which are too reliant on manual intervention.

“Tactile metrology on a CMM was discounted, as touch probing would move the spring during inspection. Trials were carried out using a laser scanner on a CMM, but the resulting point cloud gave profile data that was difficult to translate into a length measurement.

“An optical video measuring system was really the only option and we looked at three or four potential suppliers. The Nikon Metrology iNexiv solution was the only one that worked successfully and has since proved very satisfactory in operation.”

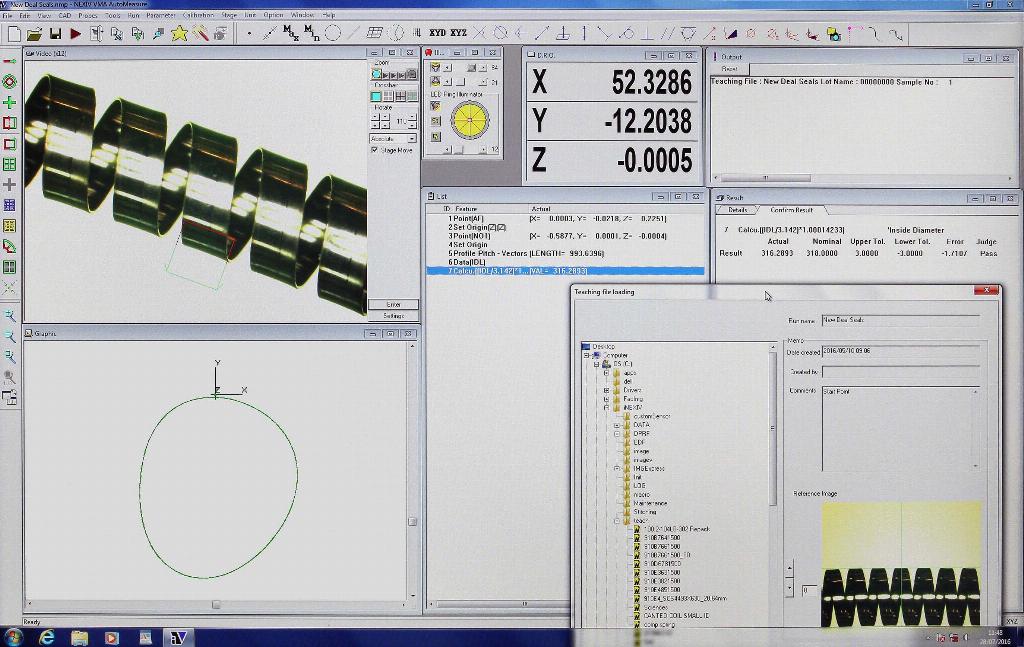

Mr Thomas went on to explain that Nikon Metrology helped Clifford Springs to co-develop a novel method for measuring a spring’s length. The iNexiv’s AutoMeasure software instructs the 2D measuring head to follow the contour of the loop automatically, repeatedly re-orientating itself and taking coordinates of points at the same height at intervals around the outside (or inside) of the spring. The operator simply has to enter the start point, end point and measurement pitch.

Peak to peak

Every measurement is taken at the peak of an individual coil of wire, which is automatically recognised, rather than in the adjacent troughs, so that the true outside or inside diameter of the spring is obtained. Between 500 and 1,000 sets of coordinates are captured, depending on the size of the spring.

Successive points are linked around the entire loop to create a series of very small, straight lines which are added together to determine the length, i.e. circumference of the spring. To allow for the fact that it is the arcs between the points that should really be totalled, AutoMeasure introduces a small correction factor that increases the measured length to arrive at the true circumference.

Each result is not only very accurate but also highly repeatable. If the shape of the same loop is altered on the iNexiv table and the measurements are taken again, the lengths recorded have consistently been shown to be within a few microns of each other.

The iNexiv VMA-4540 at Clifford Springs is currently employed exclusively for 2D inspection. The instrument does, however, have optical auto focus (AF) using the instrument’s generous 73.5mm working distance, allowing measurement of depth. The facility is not used at the moment, as coil width is easily determined manually using a Vernier calliper, but it remains a possibility if the manufacturer decides to increase the level of automation in the inspection of its products.

It is possible to fit a touch probe for capturing point data if, for example, sloping faces or undercuts need to be inspected. The probe is offset from the optical axis but works in the same 450 x 400 x 200mm coordinate space, with only slightly reduced operating range. A stylus changer is provided, so it is feasible to mix optical and tactile measurements in the same cycle.

The instrument’s versatility is further enhanced by a variety of illumination options based on episcopic, diascopic and eight segment ring LEDs. Combining these enables accurate detection of low contrast edges.

Nikon Metrology www.nikonmetrology.com