A gripping tale of workholding efficiency

Located close to the UK’s motorsport valley in Bletchley, near Milton Keynes, Dowse Engineering operates from an 11,500ft² facility and offers a comprehensive range of engineering services, including the manufacture of precision components and the machining of micro mass produced components across a range of materials and finishes.

In addition to the motorsport sector, the company undertakes work for a wide variety of clients, across the aerospace, defence, telecommunications, electronics, automotive and medical Industries, sectors that demand the supply of high-quality components that are manufactured to the most challenging of specifications, often to tight deadlines.

To help ensure the efficient and cost-effective delivery of premium quality components over the past 25 years, Dowse Engineering regularly invests in new technology – including workholding equipment from Thame Workholding.

Company director, Trevor Dowse explained. “Our highly skilled engineering staff cover a wide spectrum of engineering disciplines and we are able to produce a range of complex precision manufactured components, from single prototypes up to large batch runs – often to tight dimensional tolerances.

“Just as we work in partnership with our machine tool suppliers, we also work closely with the staff at Thame Workholding. The depth and diversity of its product range means that whenever we have explained our needs to the company’s technical staff, an efficient, cost-effective solution has been supplied to us.

“A great example of this is the many advantages we have gained through the use of Thame’s InoGrip system. Now, dependant on the application, before loading a billet onto an InoGrip vice for a milling operation, we stamp the workpiece in our InoGrip stamping station. The applied four precise depressions allow the specially shaped ends of the InoGrip vice’s three jaws to lock into the last 6mm of the workpiece. This positive fit makes it possible to securely clamp the workpiece with just a fraction of the previously necessary clamping force. In addition, this arrangement provides an absolutely precise reference point for re-inserting workpieces in the vice with a high degree of repeat accuracy.

“The much reduced machining times, improved precision and substantial cost savings on materials we have achieved through the use of the InoGrip means we anticipate a rapid return on our investment.”

The patented InoGrip Stamping system supplied by Thame Workholding results in the need for a much reduced workholding clamping force to be applied to workpieces, whilst at the same time delivering optimum holding forces across both turning and milling applications. In addition, only 6mm clamping depth is required, compared to the 20-25mm of clamping depth usually needed when using conventional gripper jaws.

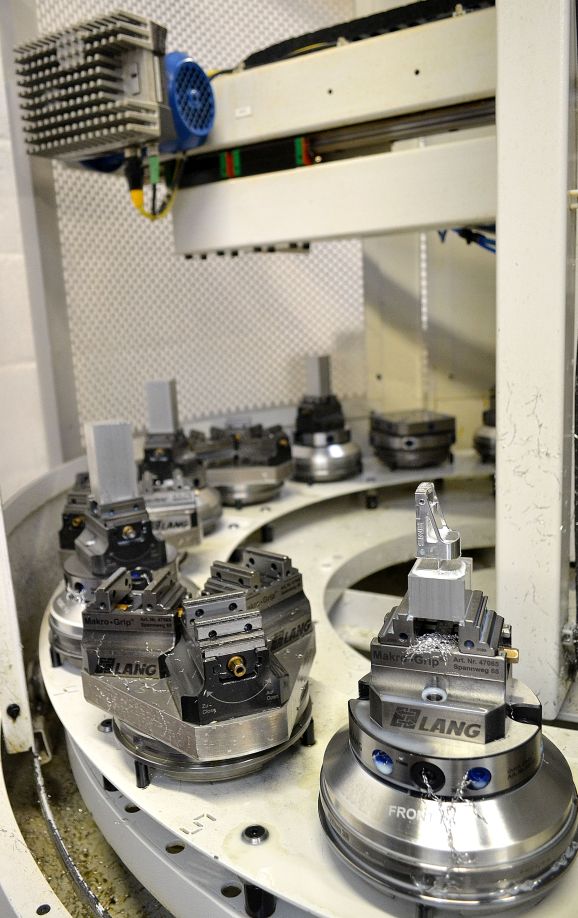

The InoGrip system uses a high-pressure hydraulic press to simultaneously apply four precise cruciform indentations to the last 6mm of the billet to be machined. The system allows all materials with a value of up to 1,400N/mm² to be stamped. Following the stamping operation, when transferred to the InoGrip chuck, the male cruciform features, located on the end of each of the chuck’s jaws, accurately engage with the workpieces’ indentations. The system produces a positive, secure fit with an impressive holding force that is up to 10 times higher than that produced by conventional gripper jaws.

InoGrip chucks can be used on all standard power chucks and deliver a wide range of advantages. When employed in turning operations, users are able to achieve the best possible roundness results on deformable workpieces. Also, when employed on milling applications, the system provides the ability to machine prismatic parts with the application of maximum cutting values.

If the billet to be machined is solid, the higher clamping pressure that can be applied through the InoGrip stamping technique means the workpiece can be securely held whilst both roughing and finishing operations are performed. Also, if secondary machining operations are to be undertaken, the pre-stamped InoGrip indentations ensure excellent repeatability of location from one machine tool to another. Last but not least, the InoGrip system’s ability to clamp on just 6mm ensures that considerable material savings are made.

Based in Long Crendon, Buckinghamshire, Thame Workholding designs, manufactures and supplies a wide range of cost-effective standard and bespoke workholding products to its global customer base. Complementing its own products, the company also provides a range of efficient workholding solutions from leading global manufacturers, such as Lang Technik, Horst Witte, Samchully and HWR Spanntechnik, on an exclusive UK agency basis.

Thame Workholding www.thamworkholding.com