Toolmaker dives into cost savings with Guhring

Since partnering with tooling specialist Guhring, a West Midlands-based press tool manufacturer has seen significant improvements in both performance and tool life. PES reports.

As a family-run business, Canterbury Tools has been involved in the design and manufacture of press tools since it was established almost 50 years ago.

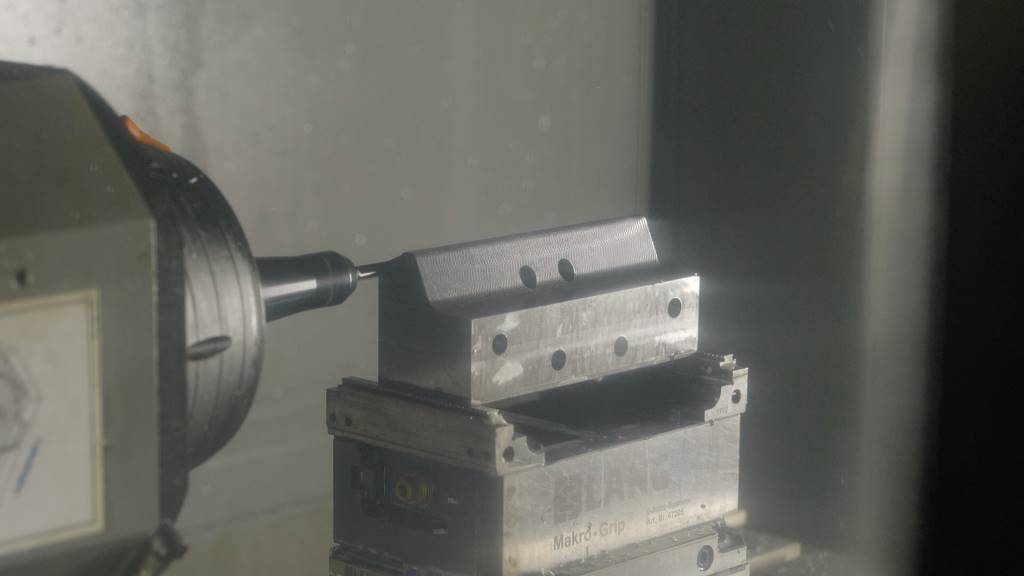

To optimise the production of specialist press tools, the Walsall subcontract manufacturer uses wire EDM machines from Sodick, machine tools from Hurco and cutting tools supplied by Birmingham-based Guhring.

The West Midlands manufacturer specialises in the production of single operation, progression, and transfer tools, as well as components and assemblies for automated and robotic processes in sectors as diverse as the agricultural and construction industries through to the medical, IT, aerospace and automotive sectors.

As a leader in the marketplace, the ISO: 9001 manufacturer is always looking for opportunities to accelerate performance and productivity – and it is this determination to succeed that led the company to Guhring.

At Canterbury Tools, the company uses a selection of 3-axis machines from small capacity to 3m bed machines as well as simultaneous 5-axis machining. Discussing the daily operation of the business, Josh Bennett, operations team leader at Canterbury Tools says: “We pride ourselves on manufacturing high-quality press tooling and this includes everything from single operation to progression tools and small fine blanking work to automotive tooling.

“Press tools can be quite complex projects, so we use a lot of different machine tools – and as technology has advanced, what was once done on manual machine tools is now moved to CNC machines.”

When the going gets tough

The company machines a lot of challenging materials that can rapidly erode tool life and profit margins if the correct tools are not selected. Alluding to this, Mr Bennett says: “We take pride in what we use in terms of cutting tools, as we have to cut very tough materials daily. This means the tool life does make a difference. We don’t cut materials like your everyday mild steel and aluminium where you can get away with using the same tools for a long time. When you are cutting things like D2 tool steel and running intricate forms with a high material removal rate, you really can burn through tools quite quickly.”

In terms of Canterbury Tools’ relationship with Guhring, Mr Bennett comments: “We were introduced to Guhring at the MACH 2022 exhibition. We have always prided ourselves on being at the forefront when it comes to cutting tools. It is an ever-evolving industry, so you have to keep up with the technology.

“When we spoke to Guhring at MACH, they made promises that we have heard from many other cutting tool companies in the past. Things like: ‘We will improve your tool life; we’ll cut your tooling costs; and we’ll improve your material removal rates’. At the time, we were in the market to improve on what we were doing and we thought we were already using very good cutters – but as always, were open to be proven wrong.”

Proving a point

Discussing the first tool that Canterbury used from Guhring, Mr Bennett continues: “The first Guhring tool was the Diver Series of end mills. We were told that it was the ideal tool for our applications and everyday use. We trialled the Diver against the tools we were using at the time and to our surprise they absolutely annihilated the performance of the apparently high-end tooling that we were using at the time.”

“We found a 3x increase in performance compared to our existing tools which was a big surprise to our management team, the accountants who deal with the daily costs of our business and most importantly to the machinists on the shopfloor.

“The machinists really saw a difference in what they were doing every single day with the new cutting tools. From this point, we took Guhring seriously and really put their tools through some rigorous testing. We saw a threefold increase in our tool life when we ran at the same speeds and feeds as our old cutters. With help from Guhring, their Navigator system and their engineers, we honed our skillset and started to use this skill to push the cutters to within an inch of their lives.”

“So we wanted to see exactly what we could get out of the Guhring tools,” Mr Bennett recalls. “We were increasing our cutting depths and stepovers by 1 to 1.5 times as well as increasing our speeds and feeds while maintaining a much higher tool life than what we were previously getting.

“By switching to Guhring, we enjoyed much higher material removal rates and this meant that jobs were on machines for less time. In the world of CNC machining, this is a big deal because you always want the job to be on and off the machine as quickly as possible.

“Additionally, not having to change the cutters as often has reduced the downtime incurred by tool changeovers. To remove, reset and replace tools is a process that can take anything from five to 15 minutes – now, the number of these tool changeovers has been drastically reduced. If you have a tool that you expect to change every hour, and then you change to a Guhring tool that gives you four hours of tool life, you have cut out three tool changes in just one job cycle. Additionally, you have slashed your tooling costs.”

In terms of Guhring’s service levels, Josh Bennett is equally complimentary: “Another advantage with Guhring is their next-day delivery. The service is excellent and if we are really stuck, they can often help us with same day delivery.

“Sometimes we will have a customer with a breakdown. If it is an automotive press tool breakdown, it can be a very costly experience, so they will want items repaired or replaced immediately. We will pull late shifts, night shifts and work weekends to get everything done – but sometimes you may not necessarily have the tooling in stock to complete the job.

“So, being able to offer customers this rapid turnaround service and adhere to very short lead-times is critical to our business – and it's something we can only offer if we have the cutting tools and support available from Guhring for the job.”

Guhring

www.guhring.co.uk

Canterbury Tools

www.canterburytools.co.uk