Winning ways with WNT

Oxford Brookes University leads the way in developing engineers of the future, many of whom go on to take prominent roles in the world of motorsport – in particular Formula One.

Virtually every team on the Formula One grid employs Oxford Brookes graduates. Driving much of this success is the University’s involvement in Formula Student, the world’s leading educational motorsport competition, under the guise of Oxford Brookes Racing.

At the launch of its 2016 (OBR16) Formula Student car team leader Chris Shawe highlighted the many successes the team has had since first entering the competition in 1999. It has been the top UK team five times; it has been at the forefront of chassis development, creating carbon monocoques, aluminium monocoques and, for 2016, developing a folded carbon monocoque chassis, which with other developments it hopes to come out top of the 630 teams that enter from around the world.

“The entire team, all 160 members, has worked extremely hard and pushed the boundaries for 2016,” Mr Shawe explains. “Since we started to enter Formula Student Oxford Brookes has scored more points, entered more competitions, produced faster laps than any other UK formula Student team. For 2016 we want to take that further and win Formula Student outright and become world beaters. We can’t achieve this without the support of our partners.”

Winning is obviously in the blood at Oxford Brookes. When Masters Student Chris Warburton attended MACH in April he visited the WNT stand as the company he is employed by, Helix Autosport, is a customer. While he was there he entered the prize draw.

As one of the winners, the University is now benefitting from his good fortune to the tune of £1,000 worth of WNT tooling which has been put to good use machining parts for the OBR16 car assisting in achieving one of the team’s goals for 2016, to reduce the mass of the car. This has the knock on effect of improving reliability as parts are under less strain and also delivering handling gain through corners.

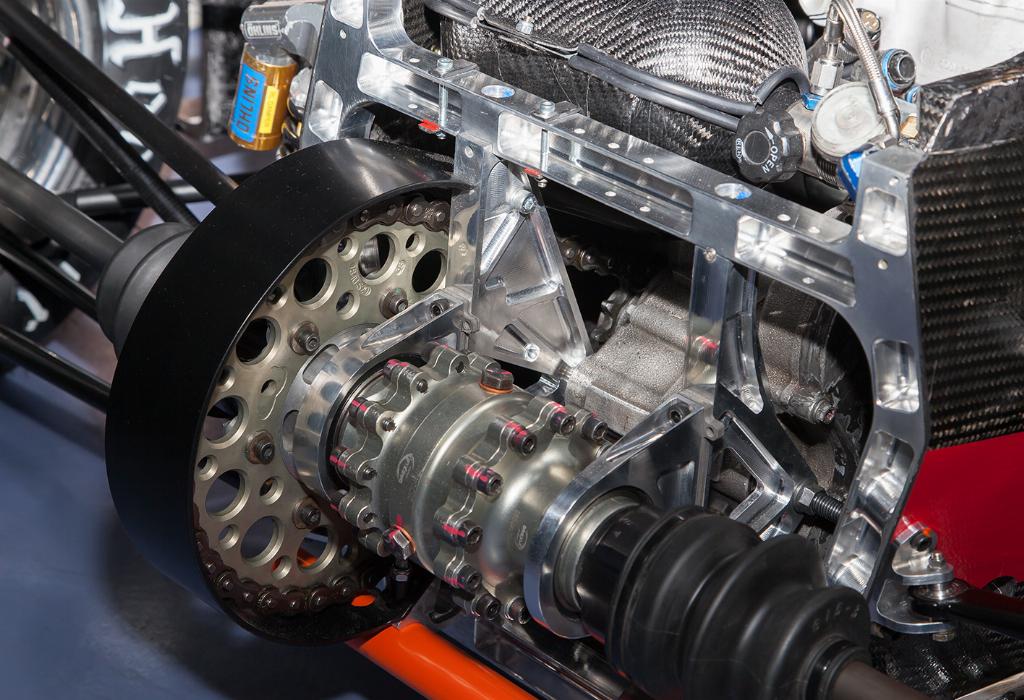

Mr Warburton adds: “The areas of focus for components that need to be manufactured to improve the development/optimisation are: suspension components which have been redesigned to be stiffer and lighter, reducing both compliance and mass; aerodynamic components to improve efficiency of the wings and the floor without increasing the mass of the aerodynamic package by more than 5%: and Powertrain components where the focus is on mass reduction, while also concentrating on components that can also reduce inertia within the system. With the help of WNT tooling we believe that this is more that obtainable.”

Since winning the tooling voucher at MACH, WNT (UK) has started to develop its partnership with Oxford Brookes University where its cutting tools can help to produce parts that are lighter and stronger – for example suspension components, an area of the 2016 car that has seen major changes. Oxford Brookes Racing competes against some of the best funded universities in the world, with some benefitting from multi-million pound budgets to develop their cars. At OBR the emphasis is less on financial power and more on engineering solutions, which may explain the success of its students as they leave university and embark on their careers.

“We are excited to be involved with Oxford Brookes and its ongoing challenge in the Formula Student competition,” WNT Oc(UK)’s managing director, Tony Pennington states. “In addition to the £1,000 prize, they are also taking advantage of our standard 50% discount to all educational establishments and we are available to offer technical support through our technical sales and applications engineering team.

“We are confident that the determination shown by the team members will lead to success sin the competition and in their future employment across the world of motorsport and engineering.”

WNT www.wnt.com