Workholding and automation technology from Thame

Experts in its field, Thame Workholding has been providing clients with workholding, chuck jaw design and manufacture for over 75 years.

Working closely with its partners at VersaBuilt robotics, it also provides solutions for integrated UR cobot machine tending, designed to improve the cost and productivity of milling and turning applications.

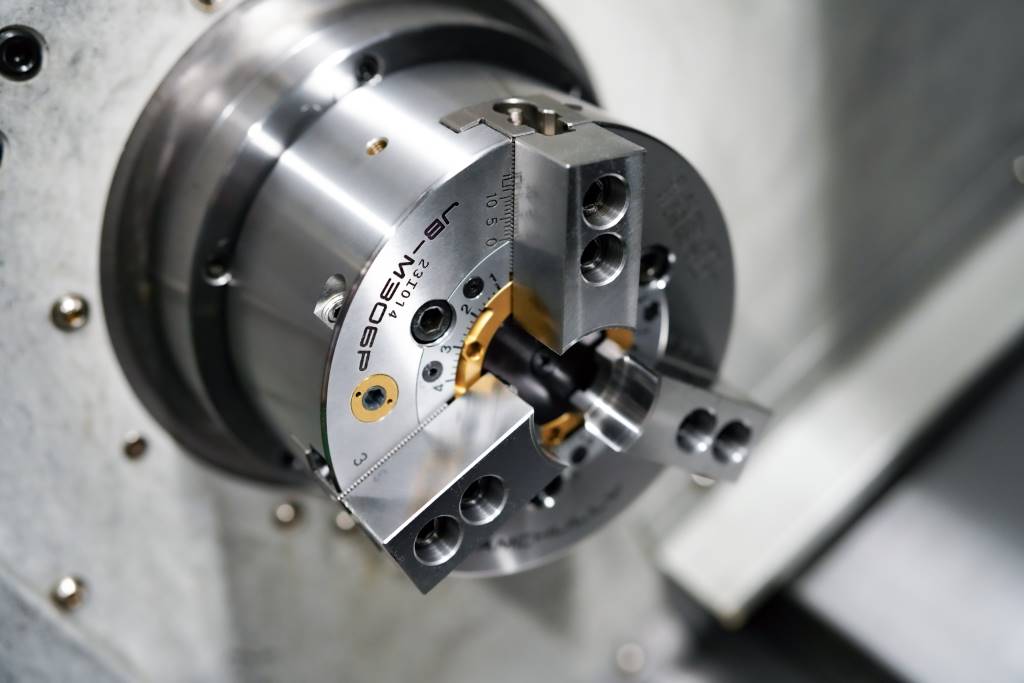

At MACH, Thame will be showcasing a large variety of workholding solutions and products. Included is the new Samchully jaw boring open centre hydraulic chuck – said to be the first of its kind to have a built-in jaw boring ring. It has been designed to reduce set-up time for boring soft jaws, increase jaw life with the ability to re-skim 0.1mm, and it is compatible with existing MH and HS chucks.

Visitors can also take a look at the Samchully HC40 (groove type) – a three-jaw power chuck and a four-jaw manual independent. It offers flexibility in both styles and is available from 800mm to 1,600mm.

Thame will have representatives from Universal Robots on the stand to discuss visitors’ cobot options and solutions. The universal cobots at the event will be set up using the VersaBuilt systems which have been designed to work seamlessly with UR cobots to provide users with a production-ready cost-effective solution.

On the stand will be the VersaBuilt universal robot machine tending cart – a simple plug and play machine tending solution designed to be ideal for companies struggling to find machine operators. Users won’t need to buy multiple vices, know how to program robots, or buy expensive ancillary equipment. The VersaBuilt mill solution allows flexibility, and quick item changeovers.

“For some hands-on interaction, visitors are invited to play our UR3 game,” enthuses Thame Workholding managing director, Mark Thomas. “Get involved and test the ease of programming a universal robot yourself and find out how easy it is to control. If the idea alone of getting to play with one for yourself isn’t enough, you might even win a prize.”

The stand isn’t all about robots: the company will also be showcasing its popular ranges of UK manufactured workholding equipment and accessories, including bespoke variants. This includes the ‘Magic Chuck’ – designed for medical applications in order to gently and securely hold acetabular liners used in hip replacement operations.

HWR has been partners with Thame Workholding for over 30 years and will have representatives on the Thame stand. HWR’s products include the HWR SOLIDLine system, a simple to use, high performance zero-point system with 96/52 combo mounting plate which offers excellent pull-down retraction forces. The innovative SOLIDBolt system along with its new big brother, SOLIDBolt MAXX system will have its first UK showing at MACH.

SOLIDBolt MAXX is suitable and approved for turning operations. With the MAXX series, holding forces of 120kN per zero-point plate can be achieved, ensuring positionally accurate and secure clamping even on large machine tables with visual clamping control

Also available is the HWR INOflex chuck, which is the original compensating four-jaw chuck (only available from Thame in the UK). On the stand the company will have the VL070, a four-jaw compensation weight reduced manual chuck. Its application capabilities include clamping round, square/rectangular and irregular shape parts, milling/turning centres and internal and external clamping. Technical features include centric compensating clamping with four jaws, centric clamping with two jaws, clamping with fixed stop, and centrifugal force compensation.

Additional brands and products to be showcased include: Witte vacuum workholding; Rotor, a leading Swiss provider of high accuracy live and dead centres; Air Vise’s table vice – ideal for maximising efficiency, running smaller parts and frequent changeovers. A T-Hook allows the jaws to disengage in an open position for rapid changeout; they will be shown as part of the cobot demonstrations.

Also on show is Rapid’s high precision pneumatic vice actuator/closer. This helps automate the CNC machine tending process by allowing a robot to load and unload the workpiece without a human operator.

Thame Workholding

https://thameworkholding.com

Hall 20, Stand 540