Built on experience

A new turn-mill centre has been introduced by DMG Mori for highly productive, complete machining of components up to 1.5m long from bar of 102mm maximum diameter.

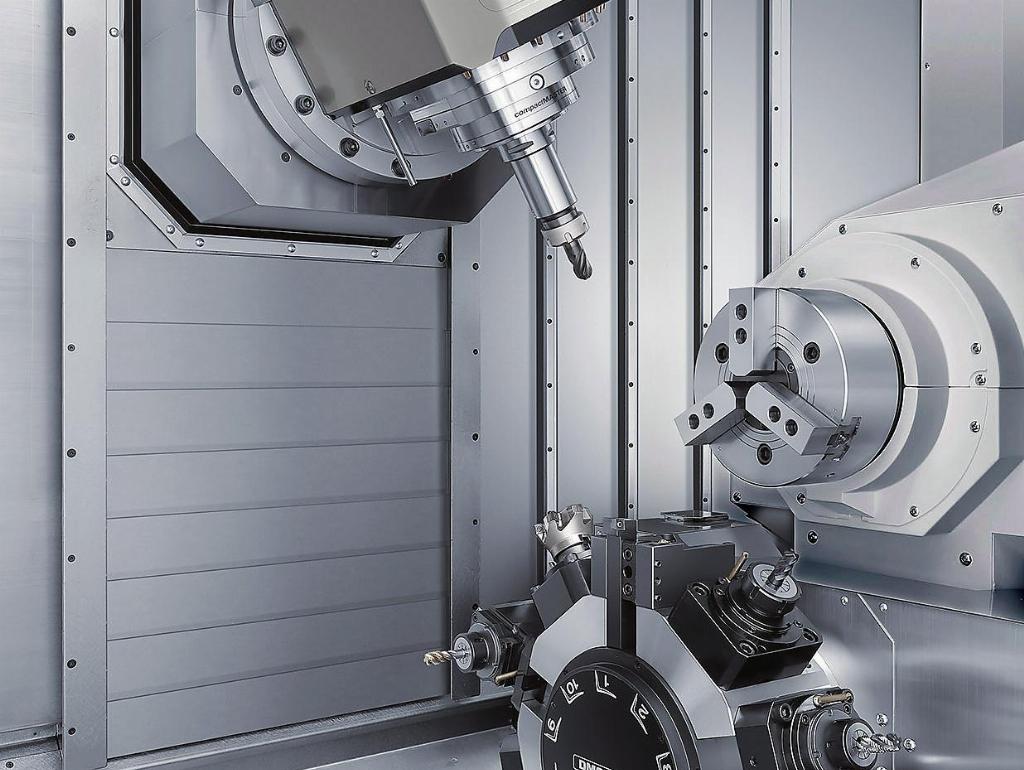

A new turn-mill centre with an upper B-axis spindle having a ±150mm Y-axis and an optional lower BMT turret with the possibility of a ±40mm Y-axis and live tooling and has been introduced by DMG Mori for highly productive, complete machining of components up to 1.5m long from bar of 102mm maximum diameter.

The generous 675mm X-axis travel of the compactMASTER direct-drive milling spindle, which is just 350mm long, to 125mm below the spindle centreline adds to the machine's versatility. It is served by a tool magazine with 38 stations, optionally expandable to 114 pockets. Tool breakage monitoring and integral tool measurement in the work area ensure efficient machining.

The NTX 3000 2nd Generation multi-tasking centre is capable of simultaneous 5-axis CNC machining of complex workpieces yet occupies a footprint of only 16.5m². The main spindle is capable of rotational speeds to 3,000rpm and has a maximum torque of 1,194Nm. A counter-spindle is optional for machining on all six faces of a component, while alternatively a tailstock may be specified.

Experience gained from installing more than a thousand of the smallest 65mm bar NTX 2000 model has been brought to bear in the design of the new machine. The latest model has a robust machine bed with roller guideways and offers high process stability and flexibility. Comprehensive water cooling of the spindles, ballscrews and ball nuts ensures thermal stability in continuous operation. Magnetic scale feedback of linear position to a resolution of 0.01µm is a further option, as is a range of automated workpiece handling systems.

The NTX 3000 2nd Generation is equipped with the proprietary Celos app-based control and user interface to either a Siemens or Fanuc CNC system. The 21-inch, multi-touch Celos display works as an Industry 4.0 interface, providing the basis for cross-company networking.

DMG Mori technology cycles are available, including Easy Tool Monitoring which monitors spindle load and axis thrust.

DMG Mori www.dmgmori.com