Good health

Matchmaker CNC has introduced a range of equipment specifically to combat the potential threat to health and environment within the workplace.

Part of a new initiative by the Leatherhead-based company, the new oil mist separator and coolant management systems will help to improve workplace and environmental conditions, with the added benefit that they can be supplied with an original machine tool order, or as a retrofit solution to help keep machines operating efficiently and the environment as healthy as possible.

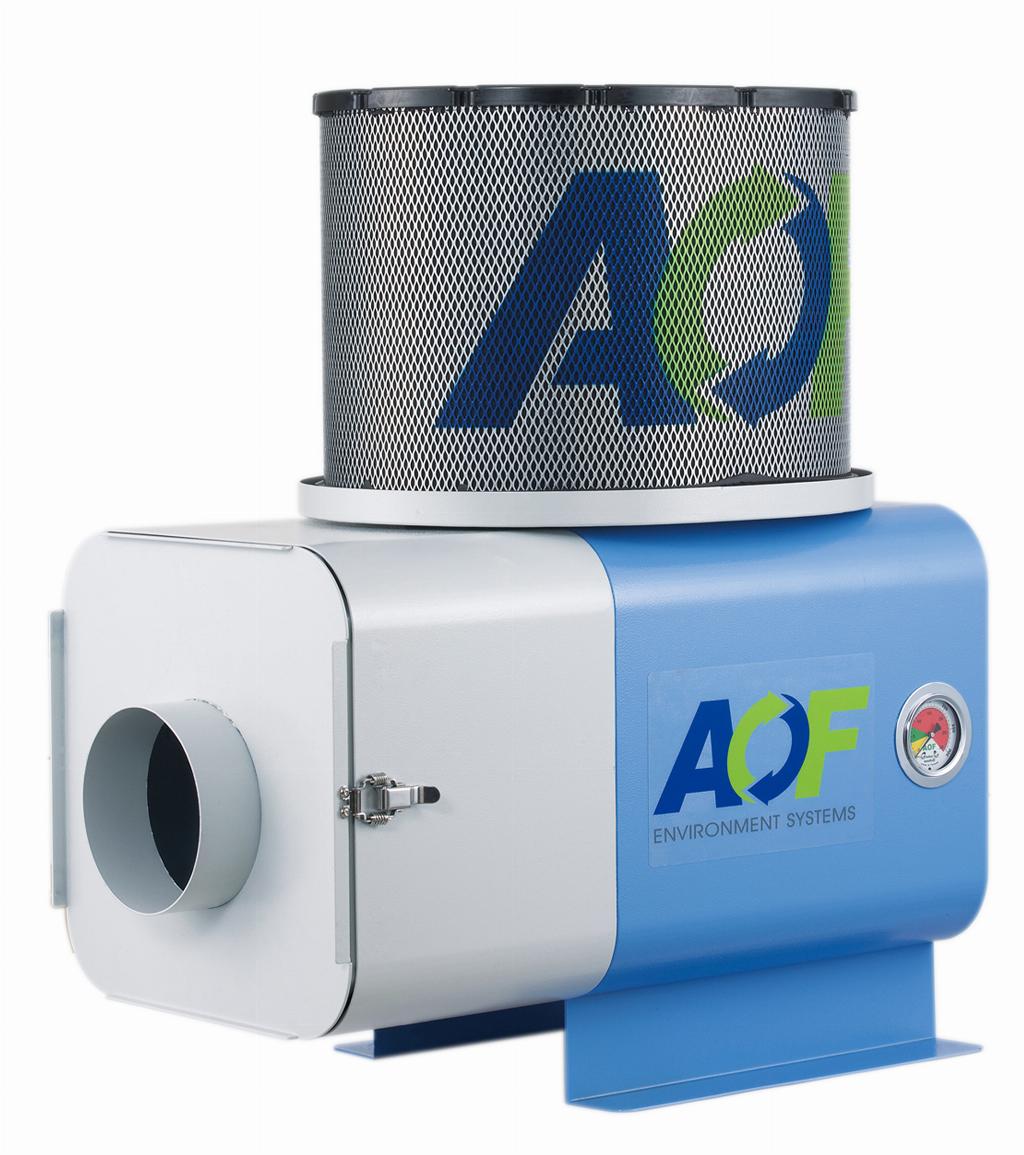

The Matchmaker oil mist extractors feature a low maintenance, patented conical filter with a service life of up to five years. Its high efficiency particulate arresting (HEPA) filter removes up to 99.97% of particulates measuring 0. 3µm, which is particularly beneficial in applications where dry smoke is created, such as when using neat oil metalworking fluids.

The filter’s performance is monitored by a pressure gauge and carbon filtration module (active carbon module available as an option) can be replaced quickly and easily when required. The oil mist filters make use of a pre-filtering system that uses the principle of wind shear to separate oil, smoke, haze and toxic aerosols; the oil is then separated for recycling.

Designed to meet all European standards and surpassing the Euro F8 and F9 limits, the Matchmaker oil filtration system is a highly efficient route to reducing the environmental impact of day-to-day machining. In addition to helping to prevent respiratory problems within the workplace and reclaim expensive oils, the filters will also reduce fire risk, reduce cleaning bills and allow users to maximise a machine tool’s potential by increasing cutting data.

Alongside the oil filtration systems, Matchmaker CNC has also introduced a series of mobile oil separators for machine coolant systems.

Maintaining the quality of metalworking fluids is vital to both efficiency and environmental concerns. Once coolant becomes contaminated it can quickly lead to bacterial growth, skin irritation and reduced machine efficiency.

Traditionally, belt-type skimmers would be used to remove tramp oil, but these can be both inefficient and also require additional manual input to remove the extracted oil. With the Matchmaker oil separator, only one unit is required to service the entire machine shop due to its mobility and requirement only for an air supply as no electricity is required to operate the unit.

While compact and easy to relocate around the factory the unit still has the capability to pump up to 400 litres of coolant per hour. Once next to a machine the system operates efficiently, removing and separating tramp oil and other contaminants from the coolant emulsion. Maintenance of the unit is also straightforward thanks to the wide use of stainless steel in its construction – the only maintenance item being the stainless steel filter that requires cleaning occasionally.

“Everyone is aware of the benefits of a clean working environment and the productivity gains that can be made by maintaining coolant correctly,” says Matchmaker CNC’s Mike Maskell. “As a machine tool supplier we were regularly asked for advice in these areas, therefore it makes perfect sense to provide these pieces of equipment either as part of an original machine order or, as one customer has just instigated, a retrofit solution to the 70 Matchmaker machining centres that it has. Being able to source these solutions from a single point of contact is also a major benefit to customers.”

Matchmaker CNC www.matchmakermc.co.uk