Geared for ongoing growth

First established in 1920, Tunbridge Wells-based Muffett Gears has gained a well-earned reputation as one of the UK’s foremost gear manufacturers and solutions providers. Even in these difficult COVID-19 shaped times the company’s gift for adaptability means it is in a strong position to prosper in future years. Ed Hill reports.

For any company to reach the 100-year landmark demonstrates a fair amount of resilience. After all, Muffett Gears – originally started by Stanley Herbert Muffett as a car repair business – has survived global conflicts, economic downturns and upturns, foreign competition, disruptive technologies and not least the current COVID-19 pandemic.

In fact, the family-owned company never actually closed this year, even during lockdown, due to its vital work providing components and assemblies for medical devices.

“We had been preparing to close the business for three weeks following Government instructions but the next day we had calls from our customers saying we had to keep on supplying them,” says operations director Mark Jagelman. “We had to issue our staff with a letter from the Home Office, via our customer, saying that we were a critical/essential supplier so that they could travel to work. We were very proud to be considered an essential company during the height of the crisis.”

Nonetheless, the business was affected by the lockdown, with a dramatic drop in sales in the first few weeks and some staff put on furlough for a time, but since then Muffett has gradually built back its sales to the point where they are almost at pre-pandemic levels.

And even during the recent difficult period the company has continued to invest in new technology, mainly linked to quality and inspection. Now considered to be just as important by the company as new metalcutting machinery when it comes to winning and growing sales.

A new Mitutoyo Crysta - Apex S CMM has just been installed, a Mitutoyo CV-3200 Formtracer contour and roughness device was being unboxed when I visited the company, and there has been a recent purchase of an Opticline C614 visual inspection system which can cut the inspection time of one gear shaft component from around 15-20 minutes to approximately 20-30 seconds.

“We have recently purchased a new Mitutoyo CMM with GearPak software installed for two reasons,” Mr Jagelman explains. “Primarily because it has much lower ongoing costs than our previous CMM but another benefit is because it gives us 100% measurement parity with one of our Japanese customers who also use Mitutoyo equipment.

“Validation and qualification of what you produce to your customers’ standards is becoming increasingly important. You can invest a lot of money on the latest gear cutting or grinding machines but if you can’t validate what you produce to your customer’s requirements it’s a major obstacle.”

An assurance for reshoring

Perhaps unusually for a UK company, Muffett not only supplies its domestic market but also exports components and assemblies overseas to OEMs in countries often considered low cost themselves. In fact, Muffett’s gear cutting expertise and attention to detail has actually enabled it to re-shore business that had previously been sourced from those countries.

There have been several contracts won where Muffett initially began inspecting and sorting the quality of components from low cost countries and was then contracted to start making them.

“If we can get close enough with our quotes, taking account of the total amount of cost for a customer such as scrap and transport, then they will decide to go with us, Mr Jagelman comments. “Sometimes it may be just a percentage of what they require but it’s primarily a need for continuity; customers these days are just as interested in quality reliability, certification, traceability and service as well as the bottom line of cost.”

Mr Jagelman is keen to emphasise that Muffett’s capabilities amount to much more than just gear production. The company likes to get involved early on in projects so it can offer not only gear manufacturing but also design advice, fabrication and electro-mechanical assembly services.

“If we are involved from an early stage it is likely we will continue as part of the supply chain,” he affirms. “We like to grow projects with the customer rather than just being asked to produce 100,000 parts out of the blue. If we are involved in the front end of a project, we can advise not just on gears but further manufacturing solutions.

“Also, we do not pass on a project just because we may not have the capability or capacity. We consider an order and look at what may be needed whether it’s more machines, new technology or more square feet and put forward a proposal. We don’t limit our business by what we can offer today. You have to be reactive and adaptable to the market these days. It’s not just your engineering that counts it’s your whole approach and the service you offer.”

Restyling production prospects

This more holistic approach is the impetus behind a forthcoming re-brand for the company as Muffett Engineering Solutions – although understandably this development, along with expansion into adjoining premises, is delayed while the company deals with what the COVID-19 situation can throw at it.

As for the future there are bright developments on the horizon. The move towards electrification for all forms of transport presents real opportunities for Muffett. In fact, the company has already been involved in the early stages of a number of projects involving electric vehicles.

“We’ve been in discussion with several companies about new projects related to hybrid systems and gearboxes. I am sure electric drive systems will be a very important new market for us, so I am optimistic we can pursue that aspect of the business more.”

The Government’s announcement that it is going to plough money into growing the UK’s sustainable forms of energy is also a potential growth market for Muffett where it can readily transfer its expertise in marine, oil and gas, fluid motion and aerospace which it has built up over its long history.

However, in the more immediate future Muffett is looking to regroup after the pandemic, expand existing contracts and invest in technology that will modernise its day-to-day operations and grow the skills of its workforce.

The company is currently implementing a new Progress Plus ERP system and looking into areas where it can apply more automation.

“Any future investment in automation is not about replacing people; it’s about enabling us to expand the business and our capacity,” Mr Jagelman asserts. “You have to adapt with new technologies. If you just carry on down the same route you will naturally become less competitive as time goes on.”

People power

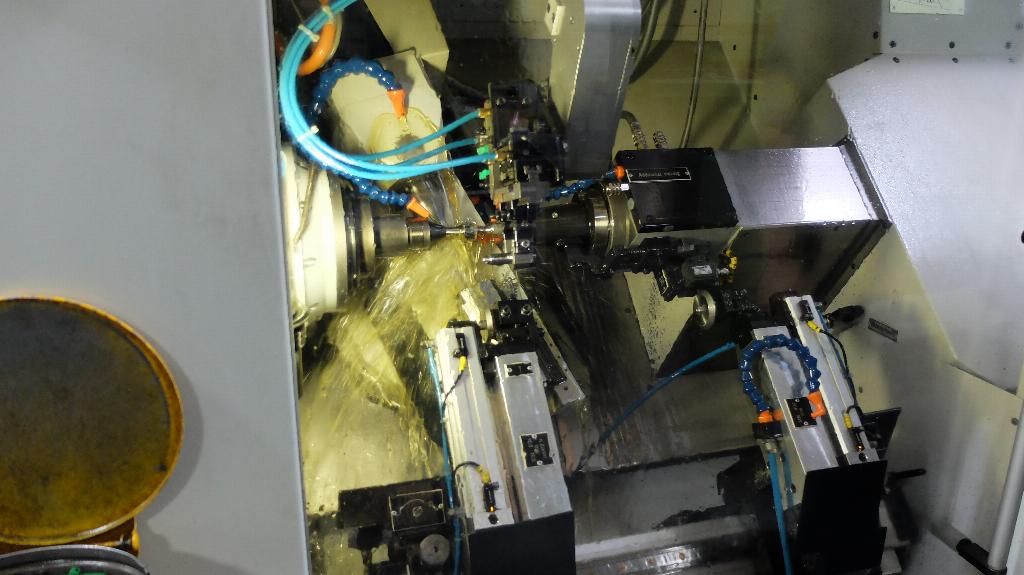

With an impressive plant list, including a state-of-the-art Liehberr LC280 gear hobbing automated production cell, Muffett has always seen the value of having a continuing policy of machine tool reinvestment.

However, Mr Jagelman is also eager to point out that the company’s staff are where he considers the most important value lies: “Investment is not just about investment in machinery; it’s also about investment in people. That’s why we run an apprentice scheme. All of our staff are multi-skilled to a certain degree. They may have specialism but they can work in other areas if they have to. I started as an apprentice over 30 years ago and now I am a director of the business, so there are opportunities to advance in the company.”

With this pragmatic but nonetheless ambitious approach there seems no reason why Muffett might not be trading for another 100 years.

“To last this long you have to continually evolve. We are very aware that we are part of a global market so you can’t afford to be complacent. China and India are always hot on our heels. Often the companies we supply to – whether they are in Europe or low-cost regions – would prefer to do the work more cost-effectively themselves, so we have to maintain a position where it’s not the best option for them to do so.

That means constantly evaluating our costs and assessing our capabilities for every aspect of the business,” Mr Jagelman concludes.

Muffett Gears www.muffett.co.uk