New insert clamping system increases sliding-head turning productivity

When grooving components radially, axially or internally to micron precision on a sliding-head lathe, or when carrying out longitudinal turning or parting-off, production output can be raised following the introduction of a redesigned insert clamping method by cutting tool manufacturer, Horn.

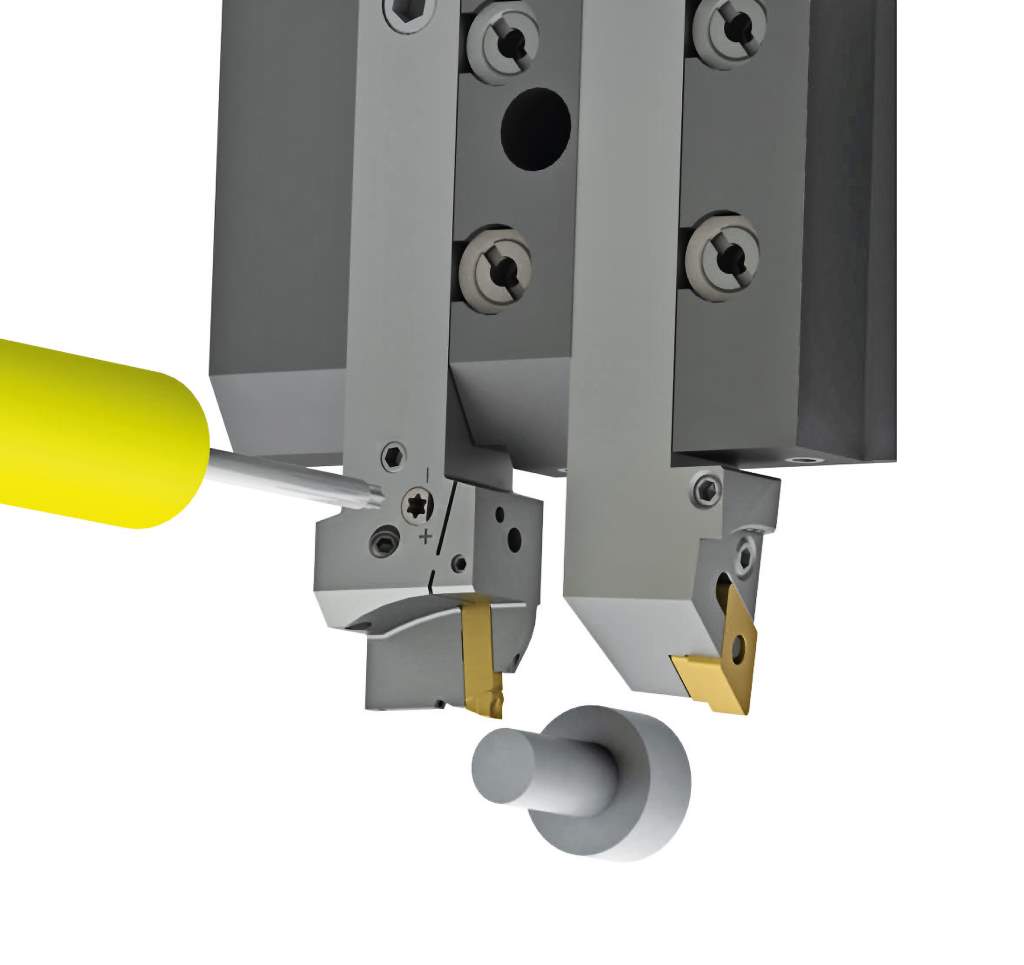

Its S224 grooving system formerly used a clamping screw on the front of the holder, but it has now been relocated to the side and changed to a cam lock action. This means that an insert can be indexed or replaced quickly without having to remove the holder from the lathe.

The screw is readily accessible from the front when the tool is sitting in the gang toolpost and the insert can easily be removed or secured using a torque wrench and star bit. The process of presenting a fresh cutting edge to the component is therefore faster, reducing downtime and maximising productivity.

The need to invest in a special quick-change tooling system is eliminated, saving expense. The 16 by 16mm square shank holder is available from stock in right- and left-hand versions. All variants of the holder are equipped with an interface for internal coolant supply.

Horn Cutting Tools

www.phorn.co.uk