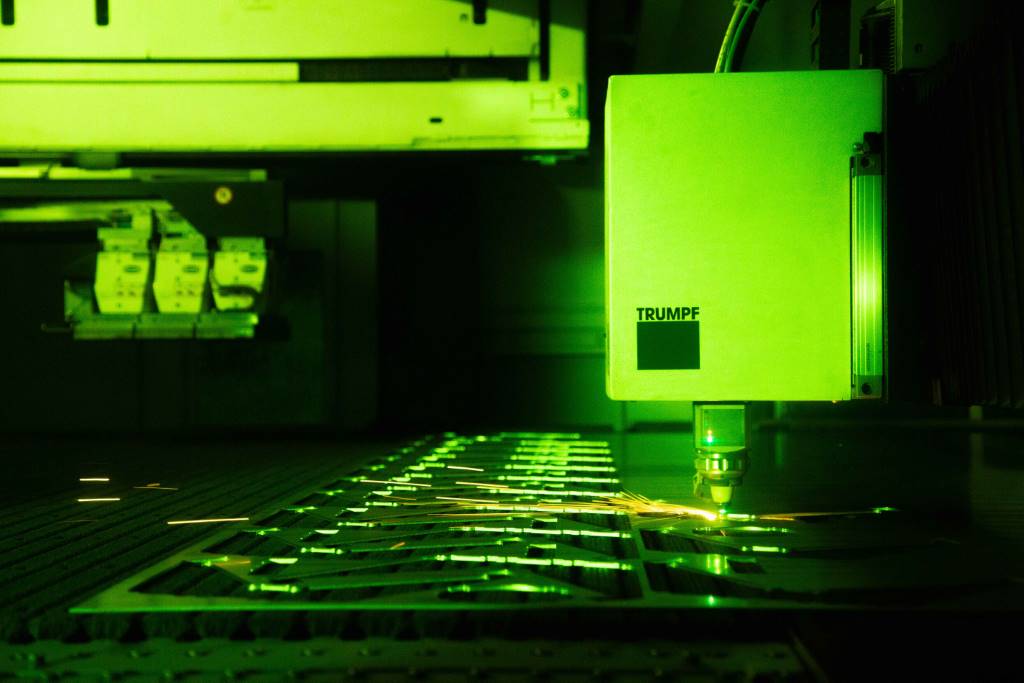

Turning night into day: Trumpf machines take over production at VDL Technics

Trumpf technology is at the epicentre of manufacturing operations at Dutch company VDL Technics. In fact the entire process is practically autonomous. PES reports.

VDL Technics, located at Boxtel in the Netherlands, is a subsidiary of the VDL Group, specialising in the manufacture and series assembly of complex metal assemblies. Its customers include companies from the agricultural, transport and mechanical engineering sectors.

The company operates across three shifts, but staff are present only during the day. During the night and on public holidays, the responsibility falls to machines, including three TruLaser Center 7030s from Trumpf. These innovative, versatile machines handle the entire machining process, from loading raw materials to producing the final parts almost completely autonomously.

Until 2021, VDL Technics had a TruLaser 3030 (4kW), a TruLaser 5030 (6kW) and a TruLaser 5030 fiber (8kW) connected to the STOPA store. Hans Sanders, managing director of VDL Technics, explains: "When these highly productive laser machines ran for approximately 150 hours during the weekend, my employees had to unload all the finished parts on Monday and store them in the STOPA warehouse.

“This process took an additional 125 to 150 hours, negating the time advantage gained from rapid cutting. And it was a repetitive task that valuable skilled workers were overqualified for.”

A machine capable of not just cutting but also automatically removing, stacking and transporting parts to the warehouse would be an excellent solution. This idea was conveyed to Mr Sanders’ contacts at Trumpf a few years ago. When introduced to the TruLaser Center 7030, which could perform exactly these tasks, Mr Sanders adopted a wait-and-see approach to assess the machine's performance in real-world applications.

And then, in 2021, the first fully automated laser machine was up and running at VDL Technics. When placing the order, Mr Sanders stipulated that Trumpf fit the machine with a 12kW laser, double the power of the standard 6 kW laser. This customisation posed no issue, and after approximately ten weeks, the machine successfully completed its initial unattended 24-hour shifts.

The VDL Group currently operates five TruLaser Center 7030 machines. In addition to Hans Sanders, who now has three fully automatic laser machines in his production facility, his counterparts at sister companies VDL Industrial Modules and VDL NSA Metaal have also embraced the process-reliable fully automatic machine.

Program and get started

VDL manufactures components, some of which are highly complex, in batch sizes ranging from 20 to 1,500 units. In addition to design consulting, the company's portfolio includes laser cutting and welding, punching and bending. "Our customers expect high-quality products with short delivery times,” Mr Sanders affirms. “This can only be achieved through automation and digitalisation. VDL Technics has achieved significant advancements in both domains in recent years, a factor that Mr Sanders views as crucial to the company's success.

The three TruLaser Center 7030 full-service laser machines are connected to a STOPA high bay storage rack, which also accommodates another laser system and a bending machine from Trumpf. A 24kW laser system is due to be added shortly.

"The only thing that is still done manually here is the storage of raw sheets in the STOPA warehouse," Mr Sanders explains. However, none of the other machines work as completely independently as its three TruLaser Center 7030s. "We program the systems offline using the TruTops Boost programming software, and that's all there is to it. From this point onwards, the machines do everything automatically.

“Given the high level of automation possible with the TruLaser Center 7030, programming is simpler compared to conventional automated laser cutting systems. My programmers adapt to the systems quickly, and the end result is a fully finished part.

Process reliability takes precedence over speed

Logistics is the most important aspect of production for Hans Sanders: "What's the benefit of fast laser cutting if subsequent processes are delayed due to manual removal, causing everything to grind to a halt," he argues.

He believes that the process reliability of his machines is significantly more important: "If a part were to get stuck during unattended cutting, it would create a problem. The TruLaser Center 7030 is equipped with a host of functions to prevent such situations.

“As an example, the SmartGate integrated into the brush tables prevents parts from tipping over. This system comprises two carriages that move in sync with the cutting head providing support for the sheet during the cutting process. An ejector cylinder, fixed to the cutting head, automatically expels the sheet metal components downward. This means that micro-joints are not required. We get top-quality parts straight away – without any post-processing.

“Punching slugs and scrap drop into a container without the cutting process being significantly interrupted," adds Mr Sanders. "That kind of thing just fascinates me."

Efficient reduction of employee workload

But the TruLaser Center 7030 not only handles unloading reliably and automatically. Depending on the material thickness and the type of part, a full-service laser machine processes up to 850kg of material per hour. This accumulates significantly over a single weekend with three machines.

“We no longer have to worry about it", says Mr Sanders. “At VDL, the SortMaster Speed stacks parts on as many as three pallets and transports them to the deposit position. And it then proceeds automatically to the TruBend Cell 5170 for bending, advancing to the next process step.

"With the assistance of the three TruLaser Center 7030s, we managed to boost our order volume by 20 to 25%. The work that this system performs reduces our employees' workload and also significantly accelerates our processes."

Looking ahead with a competitive edge

Hans Sanders is completely won over by the machine: "The TruLaser Center 7030 is unique; there’s nothing comparable on the market,” he says. “It’s perfect for suppliers who want to process a large number of top-quality parts quickly and reliably.” Mr Sanders is certain that machines such as the TruLaser Center 7030 have great potential due to growing customer requirements and the ongoing shortage of skilled labour.

Hans Sanders recalls, "Several years ago, I mentioned to my Trumpf sales representative that if they had a machine capable of self-cleaning and tidying up, I'd be interested in purchasing it." Now he leaves his production hall on Friday evenings and knows that the three TruLaser Center 7030s will continue working reliably, accurately and productively during their night shift, and will also tidy up all the finished parts afterwards.

Trumpf

www.trumpf.com