WFL reinforces its UK market presence

Linz, Austria-based company WFL Millturn Technologies will present a range of high-end technologies at MACH. In the UK, WFL was formerly represented by Kyal Machine Tools but now, following a decade of working together, a dedicated WFL Millturn Technologies Ltd UK subsidiary has been set up in partnership with Kyal which became effective in November 2023.

WFL customers enjoy tailor-made solutions. Right from the start, WFL’s mantra has been ‘clamp once – machine complete’ and that remains the foundation of the company’s technological innovations. Machining operations are increasing in complexity, so WFL is responding accordingly but the business focuses on much more than just the machining operation itself – it covers the entire process.

This encompasses the machining process, workpiece programming, simulation, production and finally, support throughout the entire service life of a machine.

WFL’s objective is to always exceed its customers’ expectations in terms of quality, reliability, and efficiency. Integrated automatic measuring solutions ensure optimum levels of process quality. These measurement readings can be recorded and monitored in the WFL Process Monitoring advanced software – essential for the traceability required in aerospace applications for example.

In terms of productivity benefits, the main advantage from using WFL’s machine tools is a reduction in the number of different machines required to produce a part. A large tool magazine helps in changeover times since all tools can be kept in the machine for different parts or different clampings. Furthermore, high rigidity for the efficient machining of exotic alloys and the compact design of the machine, as well as the latest in-machine cutting-edge metrology in conjunction with process control software rounds off the total package.

Automation partner

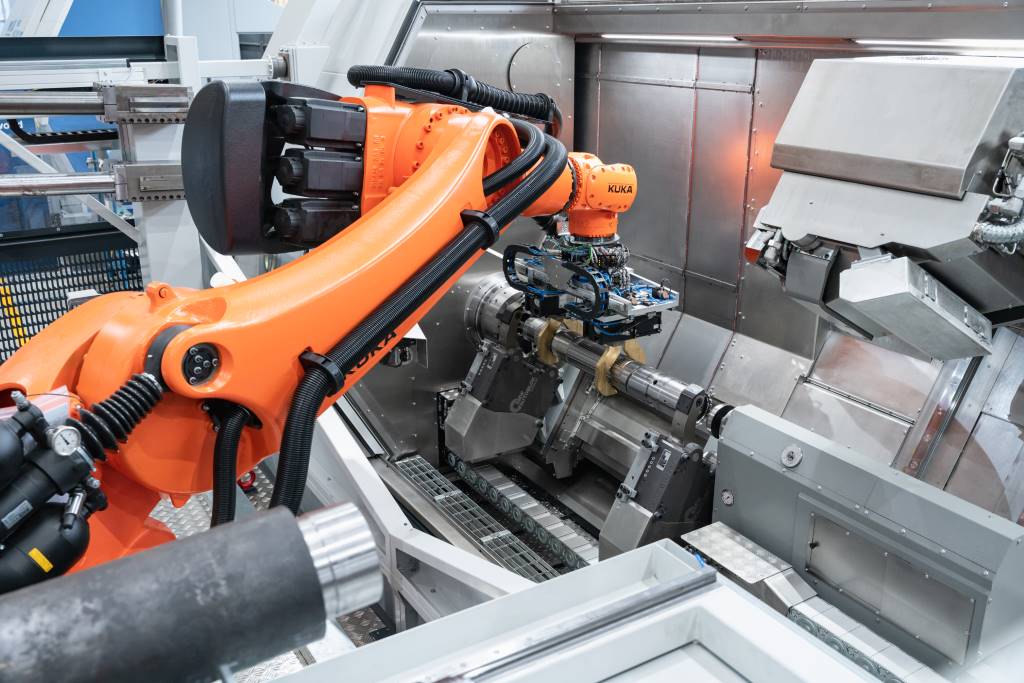

Automation tasks are becoming ever more challenging but using intelligent software in combination with automation solutions not only enables workpieces to be loaded and unloaded but also means that machine tools can be set up fully through automatic replacement of tools and clamping devices.

Together with its automation expert, Frai Robotic Solutions, WFL supports customers at all stages of their project such as initial concept development as well as implementation, commissioning, and maintenance of the automated system. Frai’s gantry robots and robot cells allow for an extensive range of high-quality automation solutions and maximum customer benefit.

The latest innovation is the mobileCELL: a generously sized automated guided vehicle (AGV) with a robot cell design comprising everything a user may need – the robot, workpiece, and tool gripper, along with buffer positions for workpieces and tools, and the necessary control and safety technology.

WFL software solutions

The realistic 3D simulation software CrashGuard Studio is the ideal tool for testing and optimising CNC programs after they have been created or modified. This can be done either on an external workstation or directly on the machine control unit. Thanks to the optimisation of the entire processing sequence and an error correction at an early stage, the risks of collisions and machine downtime are now a thing of the past.

This allows the use of a whole new range of potential features offering significant competitive advantages. CrashGuard Studio is the ideal supplement to any CAD/CAM software and the WFL CrashGuard collision prevention software. Data for workpieces, tools and clamping devices can be transferred as required.

Through the interactive graphics on the Millturn PRO programming software, NC programs can be created efficiently and easily, thereby enabling CrashGuard Studio to become a universal programming system for complex workpieces (without freeform surfaces). Additionally, WFL’s technology cycles cover an extremely broad range of standard and special technologies for all conceivable cases of application.

Furthermore, WFL offers the appropriate technological solution for every gear cutting operation – from filigree internal gears with high accuracy requirements to large external gears, which require high roughing efficiency.

WFL Millturn Technologies UK

www.wfl.at/en/

Hall 20, Stand 351